Overview:

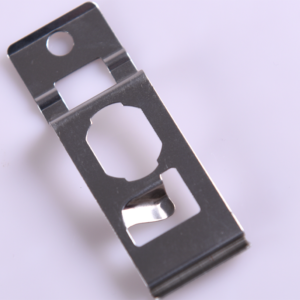

The Personalized Premium Metal Stamping Pin Contacts for Electrical Switch Socket Applications are precision-engineered conductive components designed to deliver superior electrical performance, mechanical strength, and long-term reliability. Manufactured from high-conductivity materials such as copper, brass, or phosphor bronze, and available with custom surface plating—including gold, silver, nickel, or tin—these contacts ensure stable current flow, low contact resistance, and corrosion resistance for extended service life. Using advanced progressive metal stamping technology, each contact is produced with tight dimensional tolerances to guarantee perfect fit and consistency for electrical switch and socket assemblies.

At Plantmetal, we provide fully customized OEM solutions—from tooling design to plating and packaging—to meet your unique design, performance, and branding requirements.

Features:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM / Customized |

| Material | Brass, Phosphor Bronze, Beryllium Copper, Stainless Steel |

| Thickness Range | 0.10 – 2.50 mm (custom available) |

| Tolerance | ±0.01 mm (depending on design) |

| Plating Options | Gold, Silver, Nickel, Tin, or Custom Finish |

| Process | Precision Progressive Metal Stamping, Secondary Forming, Plating |

| Application | Electrical Switches, Sockets, Relays, and Connector Terminals |

| MOQ | Small orders accepted |

| Samples | Custom samples available |

| OEM/ODM | Fully supported |

| Certification | ISO9001, IATF16949, RoHS, REACH |

| Packaging | Custom protective or reel packaging available |

Surface Treatment Options:

- Gold Plating – Provides superior conductivity and oxidation resistance for high-end or precision switch contacts.

- Silver Plating – Offers excellent conductivity at a cost-effective rate for general switch socket applications.

- Nickel Plating – Enhances wear and corrosion resistance, ensuring long operational life.

- Tin Plating – Economical and reliable, ideal for mass-market electrical components requiring solid corrosion protection.

Quality Assurance:

Every metal stamping pin contact undergoes strict quality control from raw material inspection to final testing. Our in-house laboratories perform conductivity, plating adhesion, salt spray corrosion, and dimensional accuracy tests to guarantee compliance with customer specifications and international standards. We utilize precision vision inspection systems, 3D projectors, and surface thickness testers to maintain production consistency. All manufacturing processes are managed under ISO9001 and IATF16949-certified quality systems, ensuring repeatable, defect-free results.

Why Choose Us:

- Precision & Performance: Advanced stamping and forming techniques ensure high dimensional accuracy and stable contact resistance.

- Material & Finish Expertise: Multiple metal and plating combinations available to meet both technical and cost-performance goals.

- Custom Engineering Support: In-house tool design and development enable rapid prototyping and flexible OEM customization.

- Consistent Quality & Reliability: 100% inspection for key dimensions and surface finish with traceable QC documentation.

- On-Time Delivery: Streamlined production scheduling and logistics ensure fast, reliable turnaround for both small and bulk orders.

Our Factory:

Our factory is equipped with 25 precision punch presses (25T–300T), CNC wire EDM systems, and automatic progressive stamping lines capable of high-speed, high-accuracy production. Advanced plating and surface finishing facilities—including gold, silver, nickel, and tin electroplating—ensure consistent coating thickness and superior conductivity. Supporting operations include grinding, deburring, ultrasonic cleaning, and polishing, guaranteeing smooth contact surfaces and excellent mechanical integrity.

Certified under ISO9001 and IATF16949, our manufacturing processes emphasize quality, efficiency, and environmental responsibility. Through automation, in-line monitoring, and rigorous inspection protocols, we deliver premium-grade electrical pin contacts trusted by global switch and socket manufacturers.