Overview:

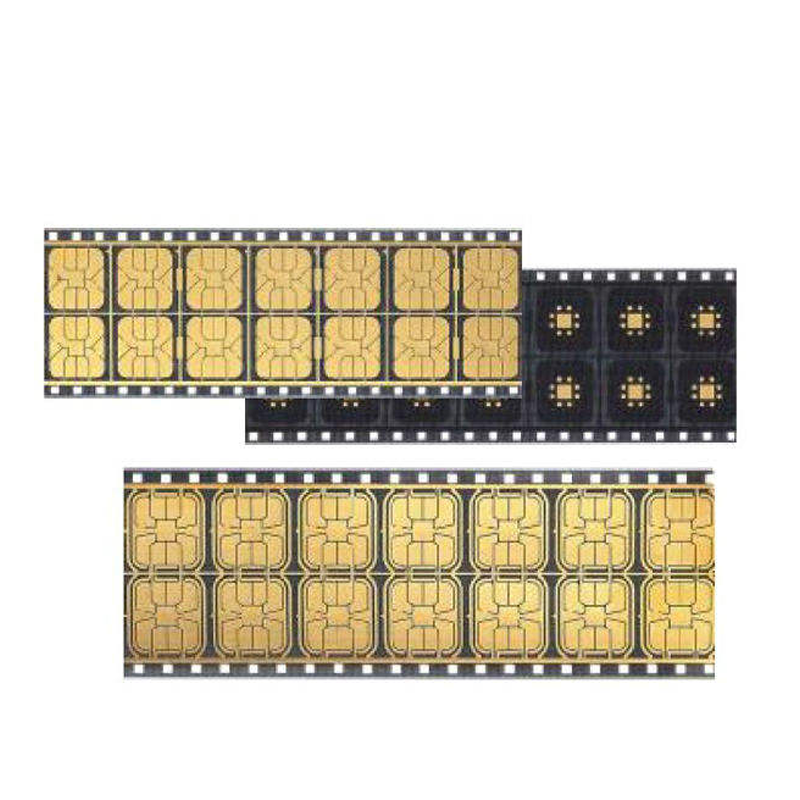

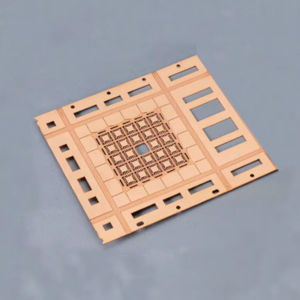

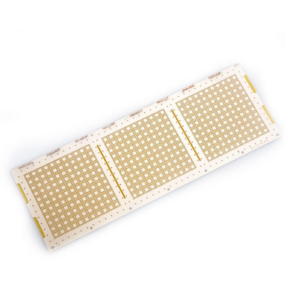

Our OEM Progressive Die Stamping IC Lead Frames with Laser Etching Service Solution is engineered for high-precision applications in the semiconductor and electronics industries. Utilizing advanced progressive die stamping technology, these IC lead frames are manufactured to meet the highest standards of electrical performance, durability, and consistency. By leveraging the efficiency of the progressive stamping process, we can produce intricate lead frame designs with tight tolerances and minimal material waste. We offer integrated laser etching services to add custom markings, part numbers, or logos, ensuring superior identification and traceability. Our OEM solutions cater to the most demanding production environments, providing reliable, high-volume production with excellent repeatability.

Basic Information

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Copper, Brass, Alloy Steel, or custom material |

| Size | Customized based on design requirements |

| Process | Progressive Die Stamping, Laser Etching |

| MOQ | Any quantity accepted |

| Package | Tape and reel, reel, PE bag, or customer-specific packaging |

| Keyword | IC Lead Frames, Laser Etching |

| Certification | ISO 9001, IATF16949 |

| Surface Finish | Tin, Nickel, Gold Plating, Silver Plating, or Custom |

| Drawing Format | 3D, CAD, DWG, STEP, PDF |

Surface Treatment Options:

- Gold Plating: Ideal for corrosion resistance and improved electrical conductivity, often used in high-end applications requiring superior performance.

- Silver Plating: Provides exceptional conductivity and durability, typically used in high-performance electronics and semiconductor applications.

- Nickel Plating: Enhances wear resistance, corrosion protection, and can withstand high-temperature environments, making it suitable for harsh conditions.

- Tin Plating: Excellent solderability, corrosion resistance, and widely used for electronic connections that need reliable performance over time.

Production Process:

- Design and Tooling:

The process begins with designing the IC lead frames using precision CAD systems. Once the design is complete, progressive stamping dies are created to match the required specifications, ensuring the frames meet all dimensional and functional requirements. - Material Selection:

High-quality metals such as copper, brass, and other alloys are carefully selected for their electrical conductivity and mechanical strength, which are critical for ensuring reliable connections in electronic components. - Progressive Die Stamping:

The material is fed into a progressive die stamping press, where it undergoes a series of precise operations, including cutting, bending, and shaping. This multi-step process in a single pass allows for high-volume, efficient production with minimal scrap. - Laser Etching:

After the lead frames are stamped, we offer laser etching services to add part numbers, logos, barcodes, or other custom markings. This process ensures high-contrast, durable, and precise markings without compromising the integrity of the material. - Surface Treatment:

Post-stamping, the lead frames undergo various surface treatments to enhance conductivity, durability, and corrosion resistance. Options like gold, silver, or nickel plating are applied based on customer specifications to meet the desired performance standards. - Quality Control and Inspection:

Rigorous quality control measures are employed throughout the production process, including visual inspections, dimensional checks, and electrical testing to verify contact resistance and overall performance. We use high-precision tools, including ZEISS CMM and 3D optical scanners, to ensure the highest accuracy. - Packaging and Delivery:

Once the IC lead frames pass all quality control checks, they are carefully packaged according to customer requirements, whether in tape and reel, PE bags, or custom packaging for ease of handling and storage during transportation.

Why Choose Us?

- End-to-End OEM Service:

From initial design and tooling to stamping, laser etching, and packaging, we provide complete OEM solutions for IC lead frame production, ensuring full customization and seamless project execution. - High-Precision Manufacturing:

Our progressive die stamping process, coupled with advanced laser etching and plating capabilities, ensures that each IC lead frame is produced with tight tolerances and superior quality. - Efficient and Scalable Production:

With extensive automation, our production lines are capable of high-volume manufacturing while maintaining the flexibility to accommodate small and medium-sized production runs. - Material and Regulatory Compliance:

We ensure that all materials and processes comply with industry standards, including RoHS, and meet the specific performance requirements of our customers in the electronics and semiconductor industries. - Customizable Solutions:

From material selection and plating options to laser etching designs and packaging, we offer fully customizable solutions to meet your product requirements and branding.

Our Factory:

Our advanced manufacturing facility is equipped with state-of-the-art machinery to ensure the highest precision and efficiency in the production of IC lead frames. We operate high-tonnage progressive die stamping presses, along with precision wire EDM machines, CNC grinding tools, and laser etching systems. Our plating capabilities include electroplating, nickel plating, and gold plating, ensuring that we can deliver consistent and high-quality finishes on all of our products. Additionally, our strict quality control processes, ISO 9001 and IATF 16949 certifications, and automated inspection systems ensure that every batch of lead frames meets the highest industry standards for performance and durability.