Description:

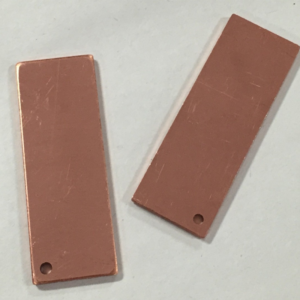

Our progressive die stamped brass terminals & connectors ensure reliable, high-conductivity connections for battery equipment. Precision-stamped from high-grade brass for excellent electrical performance and corrosion resistance, they are essential for energy storage and power systems. We offer full OEM customization.

Details:

| Item | Details |

|---|---|

| Material | High-Conductivity Brass Alloy (C2600, etc.) |

| Mould | Multi-Station Progressive Dies |

| Surface Processing | Tin Plating, Nickel Plating, Selective Gold Plating |

| Stamping Industry | Battery Equipment, Energy Storage, Power Systems |

| Tolerances | ±0.03mm (Critical Contact Areas) |

| Customization | Fully Supported (OEM/ODM) |

| Sample Time | 12-18 Days |

| Production Time | 25-35 Days (volume-dependent) |

| Service | OEM & Custom Manufacturing |

| Size | Customized per Drawing |

| Transport Package | Anti-Tarnish Bags / Reels in Cartons |

| Trademark | OEM |

| Origin | Xiamen, China |

| Production Capacity | 500,000+ units/month |

Production Process:

-

Material Selection & Blanking: Select high-conductivity brass alloy coils. The coil is fed into the progressive die for initial blanking to the required strip width.

-

Progressive Die Stamping & Forming: The brass strip progresses through die stations for precise piercing, bending, and forming into the final terminal shape in a single, high-speed operation.

-

Deburring & Cleaning: Stamped parts undergo tumbling or vibratory finishing to remove burrs and sharp edges, followed by ultrasonic cleaning to prepare for plating.

-

Precision Surface Plating: Terminals are plated via barrel or rack plating processes (e.g., tin, nickel, or gold) to ensure solderability, low contact resistance, and corrosion protection.

-

Quality Inspection & Testing: 100% visual inspection and sample-based testing for dimensions (CMM), plating thickness, and electrical conductivity/contact resistance.

-

Packaging: Components are packaged in anti-oxidation materials, wound on reels for auto-assembly, or packed in labeled boxes for shipment.

Surface Treatments:

-

Electro-Tin Plating: Provides excellent solderability and good corrosion resistance at a cost-effective price point for standard battery connections.

-

Nickel Plating: Offers superior surface hardness, wear resistance, and a stable base for subsequent plating, ideal for high-cycle mating applications.

-

Selective Gold Plating: Applied to critical contact points for ultra-low and stable contact resistance, excellent corrosion resistance, and long-term reliability in premium applications.

-

Passivation (for specific alloys): Enhances the natural corrosion resistance of the brass substrate, often used prior to plating for improved adhesion and performance.

Factory Show:

Our dedicated metal stamping facility features high-speed precision progressive stamping presses (40 to 250-ton) equipped with automatic feeders and in-line vision inspection systems for consistent, high-volume output of brass components. We maintain an in-house tool & die shop with CNC wire EDM for precision die manufacturing. A dedicated plating line handles various finishes critical for electrical components. Rigorous quality control is enforced using measurement systems like optical comparators and X-ray coating thickness gauges, ensuring every terminal meets the stringent conductivity and reliability standards required for battery and power equipment.