Description:

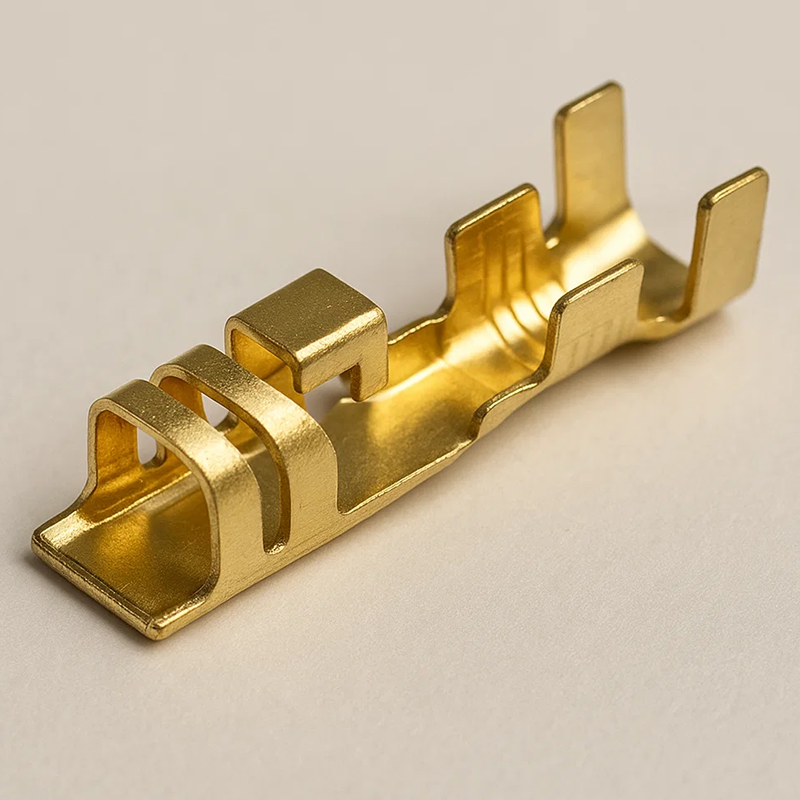

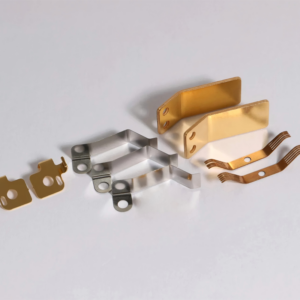

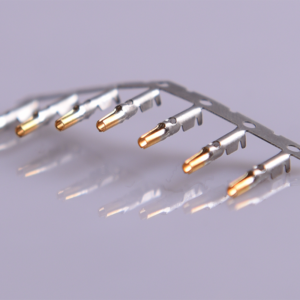

Our Bespoke Gold Plating Progressive Stamping Antifatigue Terminals & Connectors for Electric Vehicles are engineered to deliver superior electrical performance and durability in demanding EV applications. Crafted from high-conductivity copper or brass alloys, these terminals and connectors undergo precision progressive-die stamping to form intricate geometries with consistent spring characteristics and antifatigue properties. Following stamping, each component is finished with a controlled gold-plating process—ensuring optimal corrosion resistance, low contact resistance, and long-term reliability. Our end-to-end OEM service encompasses custom part design, advanced tooling development, progressive stamping, selective plating, and final assembly, providing turnkey solutions tailored to the exacting requirements of electric vehicle powertrain and battery systems.

Basic Information:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- Material: High-Conductivity Copper (C110/C102), Brass (H65), or Custom Alloys

- Gold Plating Thickness: 0.2–2.0 µm (per customer specifications)

- Packing: Custom Anti-Static, Protective Packaging

- Delivery Time: 15–25 Days

- Size: Fully Customizable to Your Drawings

- Service: End-to-End OEM Solutions

- MOQ: Flexible, Based on Your Requirements

- Shape & Configuration: Custom Designs Supported (Blade, Pin, Spring-Contact, etc.)

- Certification: ISO 9001, IATF 16949

Key Advantages of Our Solutions:

- Precision Progressive Stamping with Antifatigue Features

Delivers uniform contact spring force and enhanced flex-life, ensuring reliable performance through thousands of mating cycles. - Superior Electrical Conductivity

Utilizing high-purity copper or brass alloys combined with gold plating minimizes contact resistance and maximizes current-carrying capacity. - Long-Term Corrosion & Wear Resistance

Gold plating provides exceptional protection against oxidation and fretting corrosion, guaranteeing stable electrical connections over the vehicle’s lifetime. - Cost-Effective High-Volume Production

Optimized progressive stamping processes achieve tight tolerances and minimal scrap, enabling economical large-scale manufacturing without sacrificing quality.

Secondary Processing Services:

- Selective Gold Plating

Employs precision masking and electroplating techniques to apply gold only where needed—preserving material costs while achieving targeted contact performance. - Tin or Nickel Underplate

Deposits a thin nickel or tin undercoat (1–2 µm) before gold plating to enhance adhesion, prevent base-metal diffusion, and improve overall plating durability. - Spot Welding & Ultrasonic Welding

Provides robust wire-to-terminal or stack-assembly bonding, ensuring mechanical strength and consistent electrical continuity in multi-pin connector arrays. - Precision Laser Marking

Uses high-contrast laser engraving to imprint part numbers, logos, or traceability codes without compromising plating integrity or electrical performance.

Quality Assurance:

Our stringent quality management for Bespoke Gold Plating Progressive Stamping Antifatigue Terminals & Connectors adheres to ISO 9001 and IATF 16949 standards, reflecting automotive-grade rigor. Each production batch undergoes:

- In-Process Dimensional Verification via Coordinate Measuring Machines (CMM) to confirm precise form and tolerances.

- Spring-Force & Fatigue Testing using custom fixture rigs to validate contact resiliency over 10,000+ cycles.

- Gold Plating Thickness Measurement with X-Ray Fluorescence (XRF) analyzers to ensure uniform coating per design specifications.

- Contact Resistance Testing on automated test benches to verify low milliohm readings under specified current loads.

- Environmental Corrosion Testing in salt-spray chambers (ASTM B117) to assess plating longevity under harsh conditions.

- Visual & Surface Defect Inspection using high-resolution optical cameras and automated vision systems to detect plating defects, burrs, or micro-cracks.

These rigorous evaluation protocols guarantee that each terminal and connector delivers the reliability and performance demanded by electric vehicle battery and power systems.

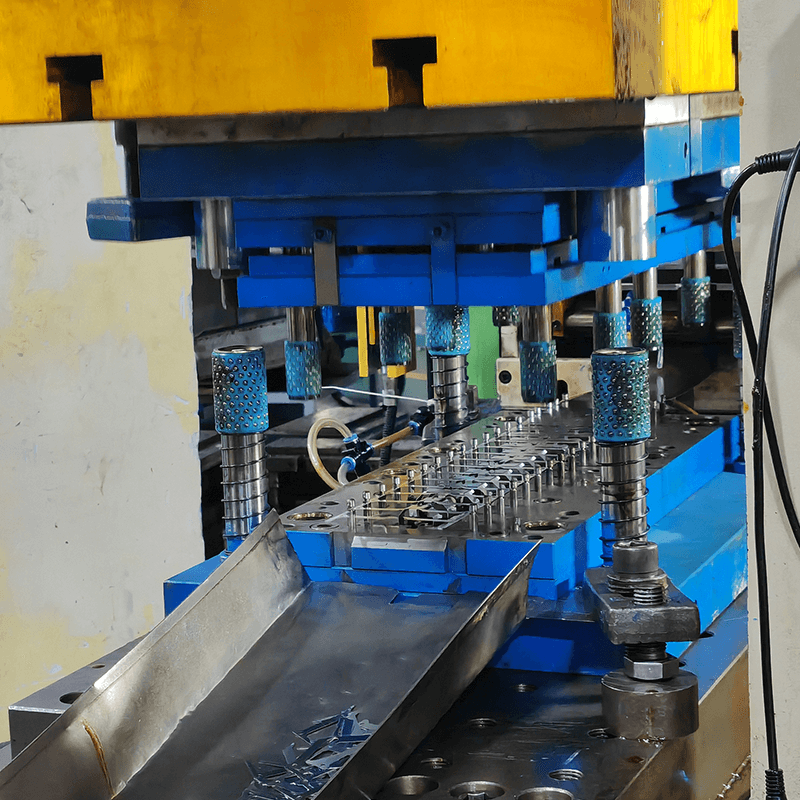

Our Factory:

Our cutting-edge manufacturing facility is outfitted with:

- 30 High-Tonnage Progressive Stamping Presses (50–500 tons) configured for multi-station operations, delivering precise, high-speed metal forming with consistent antifatigue features.

- Precision CNC Milling & Turning Centers for die maintenance, post-stamp machining, and custom fixture fabrication.

- High-Accuracy Wire EDM & Mirror EDM Systems to produce complex tooling inserts with ±0.005 mm tolerances, ensuring exceptional die longevity and part accuracy.

- Selective Plating Lines, including automated immersion stations and masking fixtures, supporting gold, tin, and nickel deposition under tightly controlled current densities and bath chemistries.

- Laser Marking & Laser Cutting Stations for permanent, high-contrast part identification and secondary shaping.

- Automated Ultrasonic Cleaning Baths to remove debris and plating residues before final assembly.

Accredited to ISO 9001 and IATF 16949, our plant integrates a dedicated QA team equipped with 3D optical projectors, XRF plating analyzers, CMMs, electrical contact resistance testers, and salt-spray chambers to uphold uncompromised quality standards. Automated material handling systems and precision die-setting equipment further enhance throughput and consistency, ensuring that every connector and terminal meets the highest benchmarks for performance, durability, and reliability in electric vehicle applications.