Overview:

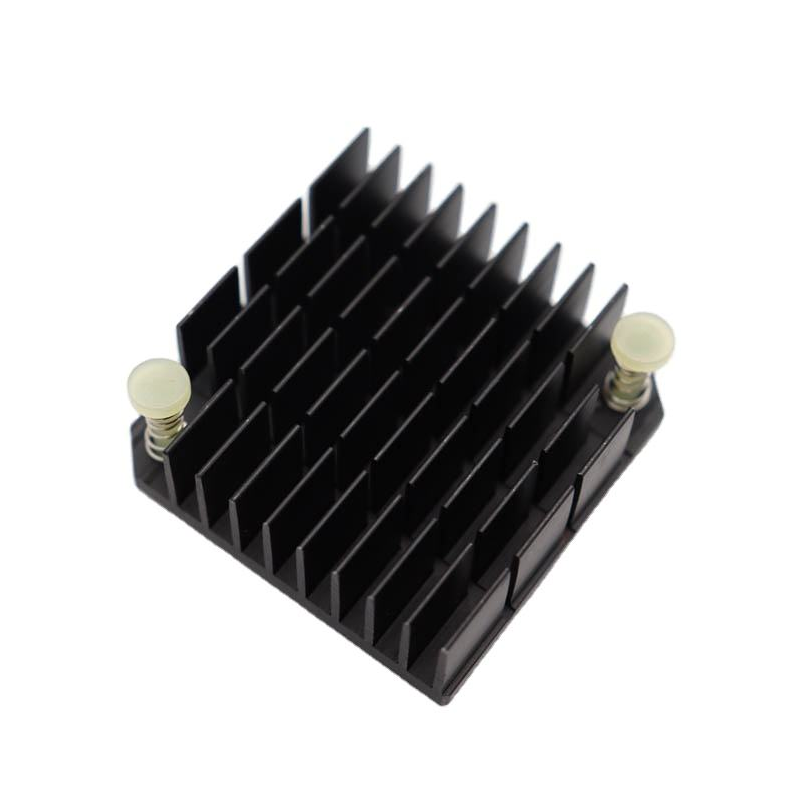

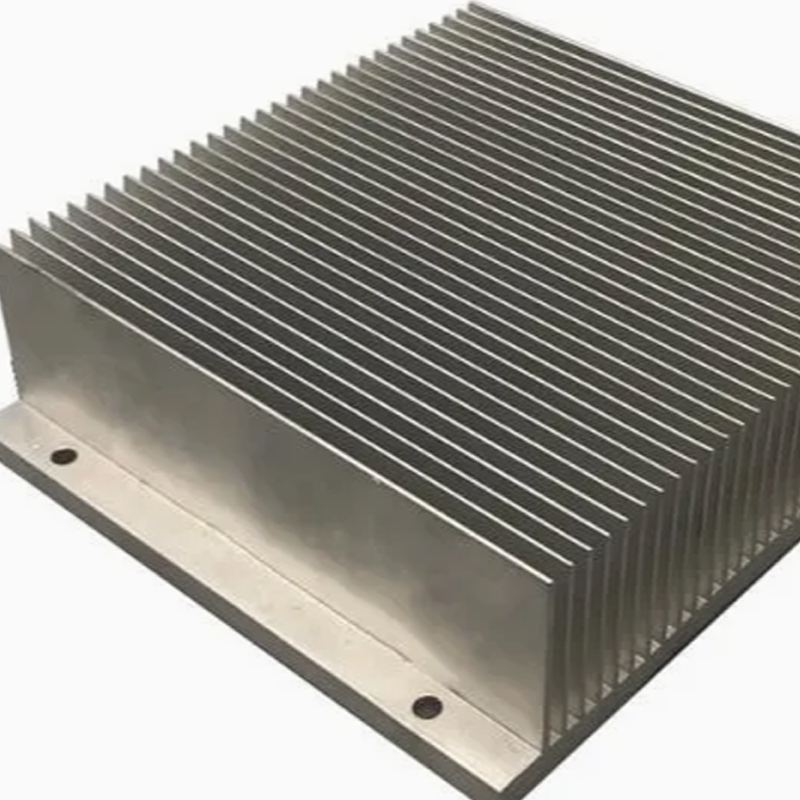

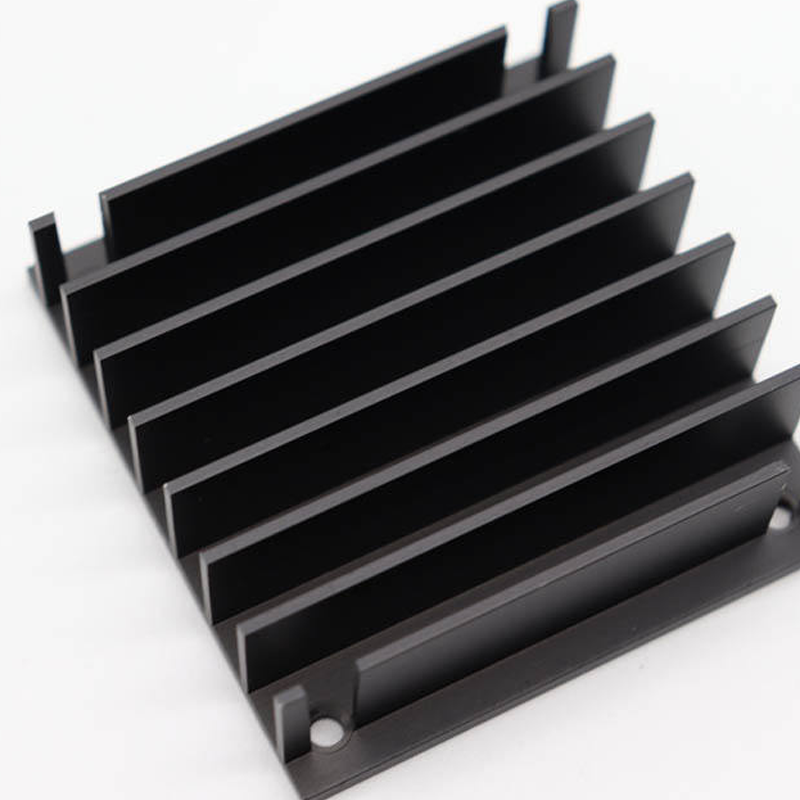

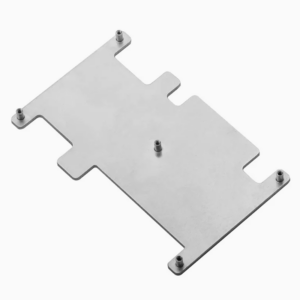

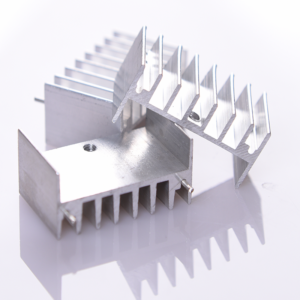

Our custom metal stamping service produces precision aluminum heat sinks through a combined process of stamping, bending, and punching. Engineered from high-thermal-conductivity alloys, these components offer an optimal balance of efficient heat dissipation, structural integrity, and lightweight design, ideal for electronics, LED lighting, and power systems.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Process | Stamping, Bending, Punching, Assembly |

| Material | Aluminum Alloy (e.g., 1050, 3003, 5052, 6061, 6063) |

| Tolerance | ±0.05mm (Typical for critical dimensions) |

| OEM/ODM | Welcome |

| QC Control | Dimensional & Visual Inspection, Thermal Performance Testing (if required) |

| Standard | ISO9001, IATF16949 |

| Size | Custom |

| Sample | Can Be Provided |

Advantages of Our Heat Sinks:

-

Optimized Thermal Management: Precisely formed fins and contact surfaces maximize surface area and thermal interface for efficient passive cooling.

-

Weight Reduction & Structural Strength: Aluminum construction provides an excellent strength-to-weight ratio, crucial for portable or weight-sensitive applications.

-

Cost-Effective High-Volume Production: The stamping process enables rapid, consistent manufacturing of complex shapes with low per-unit cost for large orders.

-

Design Flexibility & Integration: Combined processes allow for integrated features like mounting holes, snap-fits, and custom fin arrays in a single component.

Alternative Surface Treatment Options:

-

Anodizing: The most common treatment, enhancing corrosion resistance, surface hardness, and thermal emissivity. Available in various colors (black is preferred for heat radiation).

-

Chemical Conversion Coating (Chromate or Non-Chromate): Provides basic corrosion resistance and serves as a good paint base while maintaining electrical conductivity.

-

Electroless Nickel Plating: Offers a uniform, hard coating that improves wear resistance, solderability, and provides a consistent thermal interface.

-

Powder Coating: Provides superior durability, excellent corrosion resistance, and a wide range of color choices for aesthetic purposes, though it can slightly insulate heat transfer.

-

Thermal Conductive Coatings: Specialized finishes applied to further enhance surface emissivity or electrical insulation while maintaining thermal performance.

Why Partner with Us?

-

Engineering & Design Support: Our team provides expert DFM (Design for Manufacturability) analysis for your heat sink, optimizing fin design, material selection, and assembly for peak performance and cost efficiency.

-

Rapid Prototyping & Tooling: We expedite development with fast prototype samples and efficient, high-precision mold and die fabrication, getting your product to market faster.

-

Integrated Manufacturing & Quality: From blanking and forming to finishing, our in-house control of the entire process chain ensures consistent quality, shorter lead times, and strict adherence to specifications.

-

Reliable Volume Production: With automated stamping lines and proven project management, we guarantee scalable, on-time delivery for both medium and high-volume production runs.

Our Factory:

Our facility is equipped for comprehensive metal fabrication, featuring high-speed precision stamping presses (25T to 300T), CNC punch presses, and automated robotic bending cells capable of handling complex geometries with consistent accuracy. We operate advanced CNC machining centers for tool and die making, supported by laser cutting and welding stations for secondary operations. Our integrated finishing department includes automated anodizing lines and powder coating booths. Governed by an ISO 9001 and IATF 16949 certified quality management system, our production is bolstered by precision measuring equipment (CMM, profilometers) to ensure every heat sink meets stringent dimensional and performance standards.