Overview:

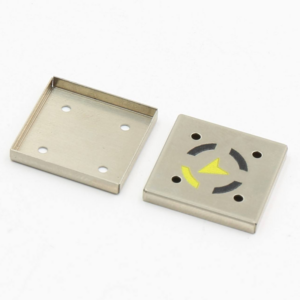

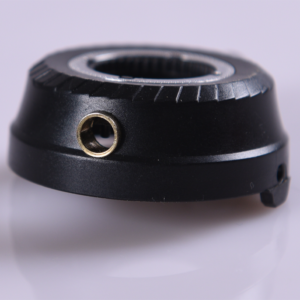

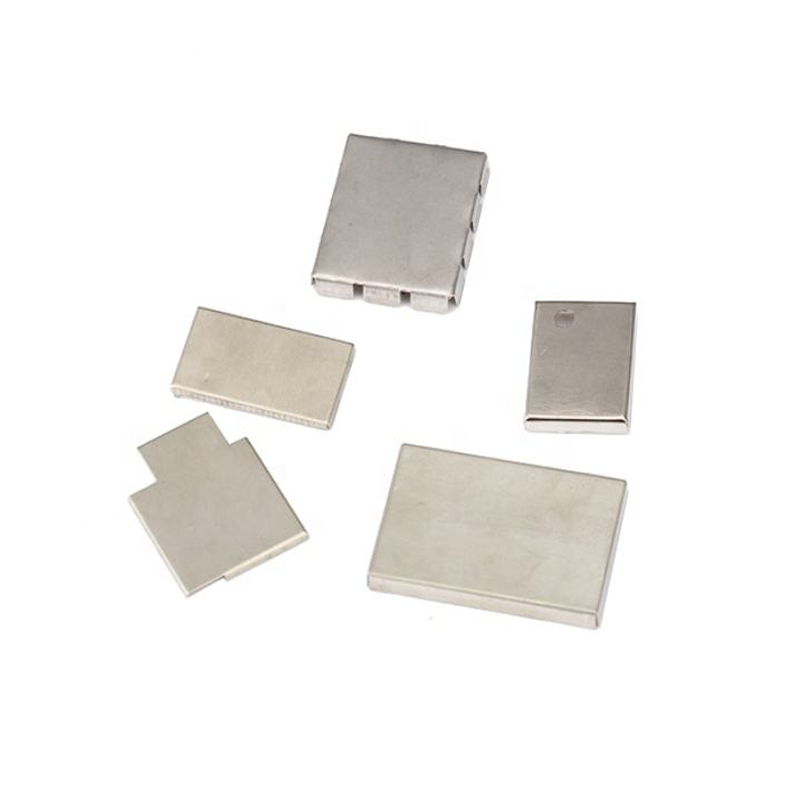

We manufacture Custom Premium Deep Drawing Electrophoretic Coating EMI PCB Shield Cases, engineered to provide superior electromagnetic interference (EMI) shielding for printed circuit boards (PCBs) in high-performance electronic applications. Constructed from premium-grade stainless steel or aluminum alloys, our shield cases deliver exceptional corrosion resistance, mechanical strength, and long-term durability.

Through precision deep drawing, CNC machining, laser cutting, and electrophoretic coating, we achieve tight tolerances, seamless edges, and consistent surface finishes. Our custom-engineered solutions are fully compatible with OEM requirements, offering tailored designs that optimize PCB integration, thermal management, and EMI attenuation. Each case undergoes rigorous testing, including conductivity, shielding effectiveness, and corrosion resistance assessments, ensuring reliable performance in demanding electronic environments. Contact us to learn how we can support your PCB shielding projects.

Features:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Stainless Steel (304/316) or Aluminum Alloy |

| Coating | Electrophoretic (EP) coating, optional plating |

| Customization | Fully available for dimensions, design, and logo |

| Sample | Provided upon request |

| Specification | Standard or fully customized to customer drawings |

| Packaging | Standard export or customized packaging |

| Color | Customizable via coating or plating |

Surface Finishing Options:

- Electrophoretic Coating (EP): Provides uniform corrosion resistance, excellent adhesion, and enhanced EMI shielding.

- Nickel Plating: Offers superior durability, corrosion resistance, and improved electrical conductivity.

- Tin Plating: Cost-effective surface protection with solderable finish for PCB assembly.

- Chrome or Zinc Plating: Provides wear resistance and long-term surface stability.

- Custom Color Coatings: Available via powder coating or electrophoretic finishing.

Quality Assurance:

Our EMI PCB shield cases undergo a comprehensive, end-to-end quality assurance process compliant with ISO 9001 and IATF 16949 standards. We start with high-purity stainless steel or aluminum alloys verified through X-ray fluorescence (XRF) spectrometry. Precision deep drawing and CNC operations are monitored for form accuracy, and dimensional inspections are performed using Zeiss coordinate-measuring machines (CMM) and 3D laser scanners.

Surface quality, coating thickness, and uniformity are verified with optical profilometers and XRF, while shielding effectiveness is validated through EMI testing chambers. Mechanical properties such as yield strength, tensile strength, and hardness are tested via universal testing machines and microhardness testers. All materials comply with RoHS and REACH requirements, and full traceability is maintained via serialized lot coding.

Our Factory:

Our advanced manufacturing facility is equipped with cutting-edge technologies to ensure exceptional precision and repeatable quality. Production lines include high-tonnage deep drawing presses, CNC milling centers, laser cutting systems, and advanced bending/forming machines, supported by precision welding, polishing, and ultrasonic-cleaning stations to achieve superior surface finishes.

We provide comprehensive surface treatment services, including electrophoretic coating, nickel, tin, zinc, and chrome plating, to meet stringent corrosion and conductivity requirements. Automated lines combined with rigorous QC protocols, including CMM inspections, 3D scanning, and EMI testing, guarantee reliable, high-performance results across all production stages. ISO 9001 and IATF 16949 certifications reinforce our commitment to manufacturing excellence and product reliability.