Overview:

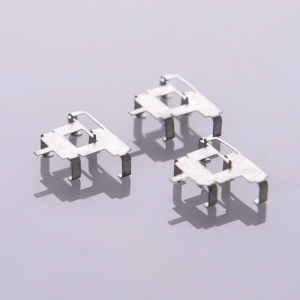

Custom Sheet Metal Stamping Brass Plate Contacts for Electronic Terminal Accessories are precision-engineered components designed for high-performance applications in the electronics industry. Crafted from high-quality brass, these contacts are essential for ensuring optimal electrical conductivity and secure connections in a variety of electronic devices, including circuit boards and terminal accessories. Using advanced metal stamping techniques, we produce highly durable and reliable components tailored to meet the specific demands of your project. Our products are designed to enhance the performance and longevity of your electronic systems, delivering exceptional functionality in critical applications.

Basic Information:

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | OEM |

| Material | Brass |

| Size | Custom |

| Color | Customized |

| Logo | Custom logo printing available |

| MOQ (Minimum Order Quantity) | Based on customer requirement |

| Packing | Custom packaging options available |

| Process Technology | Metal Stamping |

| Lead Time | Approx. 30 days |

| Certification | ISO9001, IATF16949 |

Manufacturing Process:

- Material Selection and Preparation:

- High-quality brass is selected and prepared for the specific needs of your application to ensure optimal performance and durability.

- Tooling and Die Design:

- Precision tooling and die designs are created based on the part specifications to ensure consistency and accuracy throughout production.

- Metal Stamping:

- Brass materials are fed into precision stamping presses where they are cut, shaped, and formed into the desired configurations to meet design specifications.

- Cleaning and Surface Treatment:

- After stamping, the components are thoroughly cleaned. Surface treatments such as electroplating, gold plating, or nickel plating are applied to improve durability and electrical conductivity.

- Inspection and Quality Control:

- Each component undergoes rigorous inspection and quality control to verify that it meets dimensional specifications and performs reliably under high-demand conditions.

- Final Assembly and Packaging:

- If required, components are assembled, securely packaged, and prepared for shipment to ensure protection during transit and delivery.

Advantages of Custom Sheet Metal Stamping Brass Plate Contacts:

- Durability:

- Brass provides a strong, corrosion-resistant material that ensures consistent and reliable performance in harsh environments.

- Excellent Electrical Conductivity:

- Brass is an excellent conductor of electricity, making these contacts ideal for applications where high conductivity is essential.

- Cost-Effective:

- Metal stamping is a highly cost-effective manufacturing process, particularly for large volumes of parts, helping reduce overall production costs.

- Customizable Design:

- Tailored to meet the specific requirements of your application, these brass plate contacts can be customized in size, shape, and surface treatment to fit your needs.

Surface Treatment Options:

- Passivation:

- Provides enhanced corrosion resistance by forming a protective oxide layer on the metal surface.

- Gold Plating:

- A thin gold layer improves electrical conductivity, corrosion resistance, and offers a visually appealing finish, especially in electronic applications.

- Silver Plating:

- Silver plating enhances electrical conductivity and solderability, making it ideal for connectors and terminals in electronic devices.

- Nickel Plating:

- A nickel coating enhances hardness, wear resistance, and corrosion protection, commonly used in automotive and industrial applications.

- Tin Plating:

- Tin plating increases corrosion resistance and solderability, often used for electronic connectors and terminals.

OEM and Custom Services:

We offer comprehensive OEM and custom services to meet the specific requirements of your project. From design and prototyping to final production and packaging, we provide a seamless, end-to-end service. Whether you need unique dimensions, custom surface treatments, or specific packaging solutions, our team will work closely with you to deliver the perfect solution for your needs. Contact us today to learn more about how we can help optimize your electronic systems with our high-quality brass plate contacts.

Factory Overview:

Our state-of-the-art manufacturing facility is equipped with 25 punch presses ranging from 25 to 300 tons, as well as precision wire EDM machines, grinding tools, and ultrasonic cleaning systems. These advanced technologies ensure the production of high-quality sheet metal contacts with exceptional accuracy and performance. Additionally, we offer a wide range of metal plating services, including electroplating, zinc plating, nickel plating, and chrome plating, all designed to meet industry standards and provide superior durability and corrosion resistance.

With ISO 9001 and IATF 16949 certifications, we integrate automated production lines and stringent quality control measures to deliver top-tier brass components for electronic terminal accessories. Our commitment to excellence ensures the reliable, high-performance manufacturing of custom metal stamping products that meet the most demanding specifications.