Overview

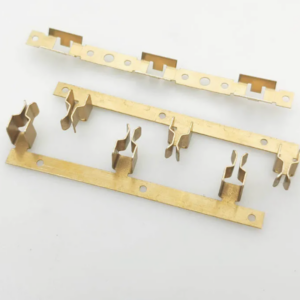

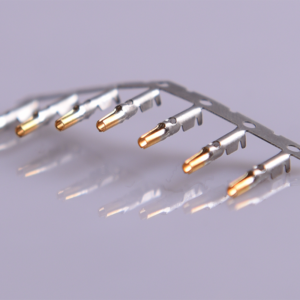

Our Customized High-Quality Metal Stamping Battery Terminals & Connectors are precision-engineered for superior electrical conductivity and durability in demanding power applications. Manufactured from high-grade copper alloys via advanced stamping and plating, they ensure reliable, low-resistance connections for automotive, industrial, and energy storage systems.

Characteristics

| Attribute | Details |

|---|---|

| Place of Origin | Xiamen, China |

| Brand Name | White Label / OEM |

| Material | C11000 Copper, C5191 Phosphor Bronze, Brass, Aluminum |

| Thickness Range | 0.5 mm – 3.0 mm |

| Dimensions | Customized per drawing or 3D model |

| Surface Finish | Tin, Nickel, Silver, or Gold Plating |

| Current Rating | Up to 500A+ (Design Dependent) |

| Tolerance | ±0.05 mm (Tighter on Critical Features) |

| Treatment Options | Electroplating, Passivation, Heat Treatment |

| Process | Progressive Die Stamping, CNC, Welding, Plating |

| Certification | ISO 9001:2015, IATF 16949:2016, RoHS, REACH |

| Application | EV Batteries, Energy Storage, UPS, Industrial Power |

| Sample | Available |

| MOQ | Flexible |

Surface Treatment Options

-

Tin Plating: Provides excellent solderability, good corrosion resistance, and cost-effective protection for general-purpose connections.

-

Nickel Plating: Offers superior corrosion and wear resistance, ideal for high-temperature or harsh environment applications.

-

Silver Plating: Delivers the highest electrical and thermal conductivity for critical, high-current power transmission paths.

-

Gold Plating (Selective): Ensures exceptional corrosion resistance and stable contact resistance for low-voltage signal or data contacts within hybrid connectors.

-

Anti-Oxidation Passivation: A chemical treatment for bare copper surfaces to prevent tarnishing during storage and assembly.

Quality Assurance

Our quality assurance for battery terminals is governed by our IATF 16949 certified system. We enforce strict material certification and traceability. Each production batch undergoes dimensional verification with optical comparators and CMM, plating thickness and composition analysis via XRF, and critical functional testing. This includes micro-ohm resistance measurements, tensile pull-force tests on crimped joints, and salt spray testing to validate corrosion resistance, ensuring every component meets precise electrical and mechanical specifications for reliable, long-term performance.

Factory Show

Our vertically integrated factory features high-speed progressive stamping presses (25-300 tons) and CNC machining centers for precision forming. In-house, automated plating lines perform tin, nickel, and silver electroplating with strict process control. Quality is embedded through SPC monitoring, automated optical inspection (AOI) for defects, and a fully equipped lab for electrical and mechanical validation, including XRF analyzers and precision resistance testers. This end-to-end capability ensures consistent, high-performance battery terminals and connectors from prototype to mass production.