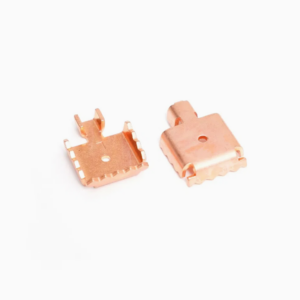

Overview:

The Customized Precision Stainless Steel Pressure Washer Adapter Connector Set is a high-performance component designed for use in pressure washing systems. Manufactured from premium stainless steel, these connectors offer exceptional durability, corrosion resistance, and high-pressure tolerance. The precise engineering and advanced machining techniques used in the production of these adapters ensure superior performance, long-lasting reliability, and a secure, leak-proof connection. With our expertise in OEM and custom manufacturing, we provide tailored solutions to meet specific needs, ensuring each adapter set is optimized for maximum efficiency in pressure washing applications.

Features:

- Place of Origin: Xiamen, China

- Brand Name: OEM

- MOQ: Small orders accepted

- Color: Custom

- Service: Customized OEM

- OEM: Accepted

- Certification: ISO9001, ROHS

- Sample: Custom samples available

- Size: Custom sizes available

Surface Treatment Options:

- Polished Stainless Steel – Delivers a sleek finish and superior corrosion resistance, making it ideal for high‑pressure applications where aesthetics and durability are key.

- Electroplated Coatings – Zinc or nickel plating for added resistance to corrosion and wear, offering enhanced longevity and performance under extreme conditions.

- Passivated Stainless Steel – A surface treatment that increases the stainless steel’s natural corrosion resistance, providing longer-lasting performance in aggressive environments.

Quality Assurance:

Each adapter set is rigorously inspected throughout the production process to ensure precise dimensions, durability, and optimal functionality. We use advanced machining techniques, including CNC machining and precision cutting, to achieve exact tolerances. After production, each set undergoes various tests such as pressure resistance, dimensional accuracy, and surface durability to ensure the highest performance standards. Our production process is certified under ISO 9001 and ROHS, demonstrating our commitment to quality, safety, and environmental responsibility.

Why Choose Us?

- Cost-Effective Solutions

We offer competitive pricing with factory-direct rates, ensuring you receive high-quality products at the best possible value. - Stringent Quality Control

Our quality assurance system, which includes first article inspections, in-process testing, and final product evaluations, adheres to ISO 9001 and IATF 16949 certifications, ensuring consistent top-tier quality at every production stage. - Comprehensive Customer Support

From pre-sales consultation and product development to after-sales service and logistics, we offer full-spectrum support to ensure that your needs are met at every step. - Reliable and On-Time Delivery

With efficient project management and a commitment to punctuality, we ensure that all orders are completed and shipped on schedule, with no delays.

Our Factory:

Our state-of-the-art manufacturing facility is equipped with cutting-edge machinery, including high-precision CNC machines, precision wire EDM, grinding equipment, and advanced welding tools. This allows us to produce high-quality pressure washer connectors with exceptional dimensional accuracy and surface finish. We also offer a full range of metal plating services, including zinc, nickel, and chrome plating, to enhance durability and corrosion resistance. With automated production lines and stringent quality control measures, our operations are ISO 9001 and IATF 16949 certified, ensuring the highest production standards for every connector set.