Übersicht:

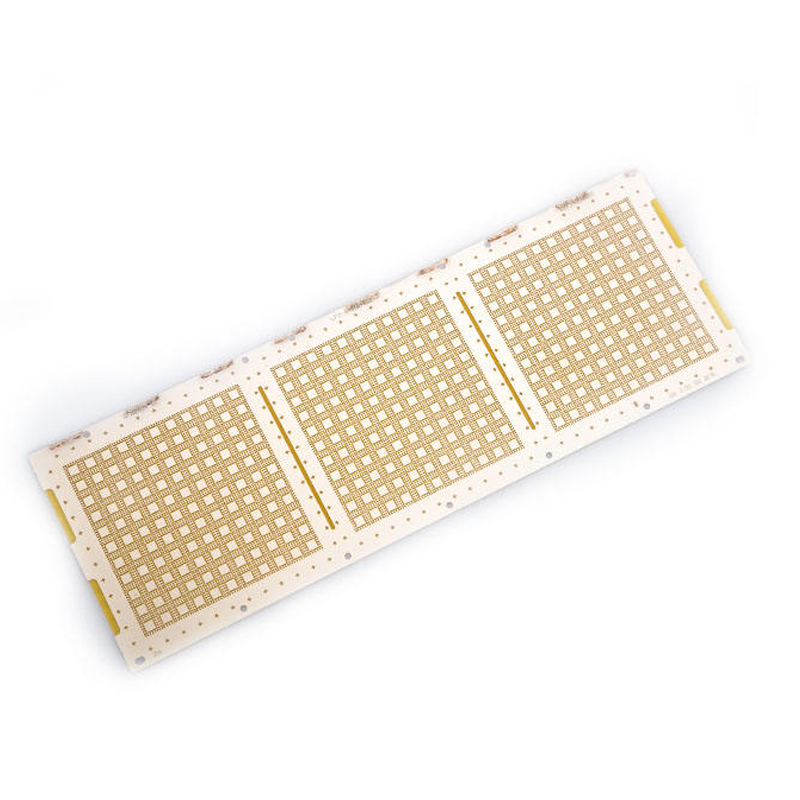

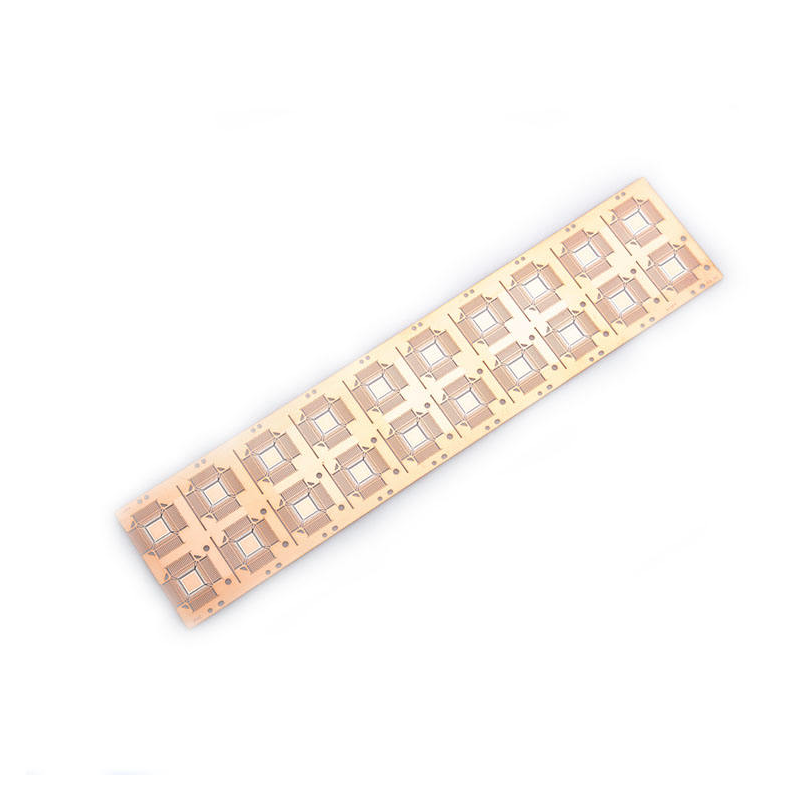

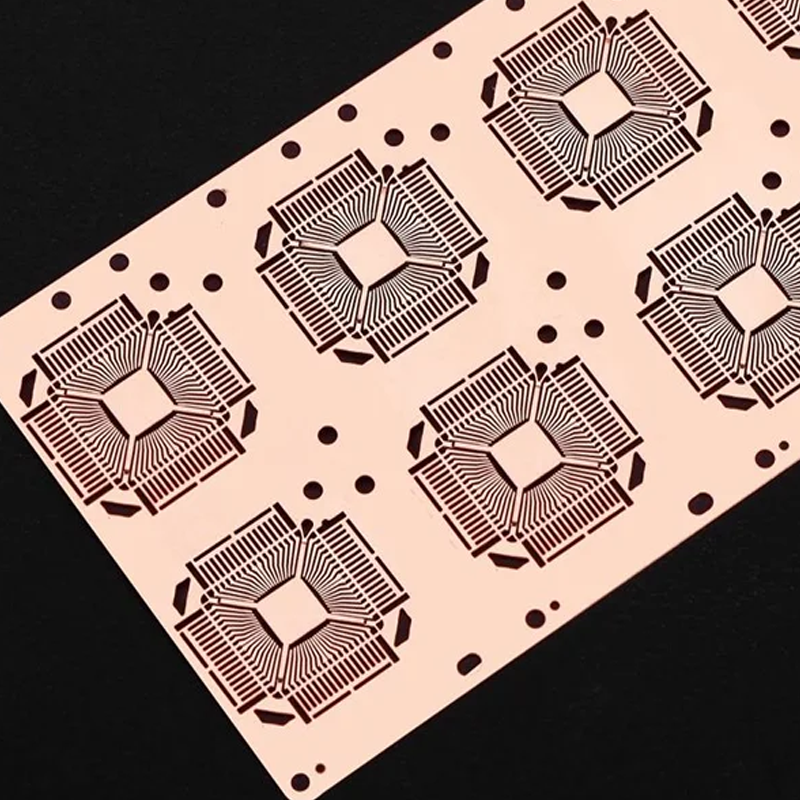

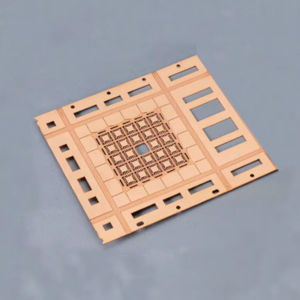

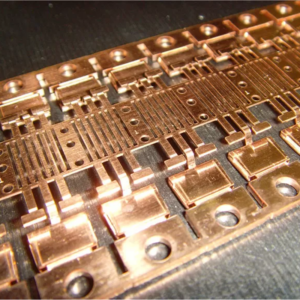

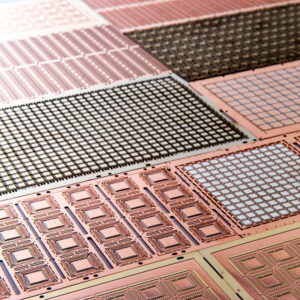

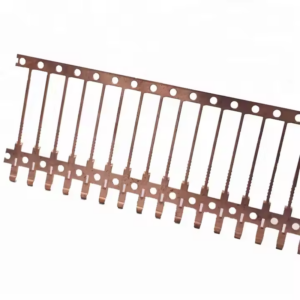

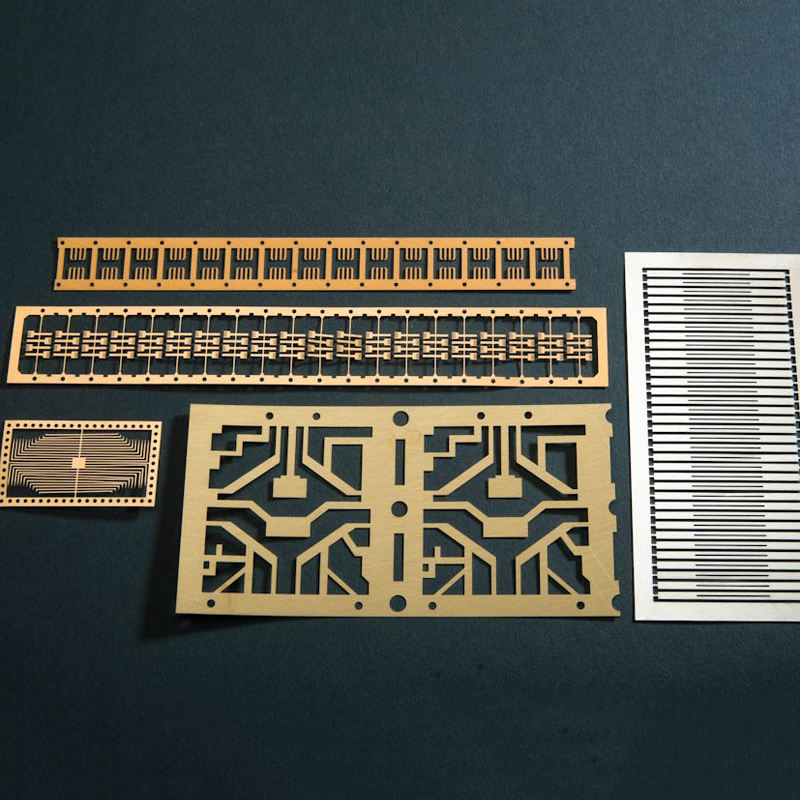

Maßgeschneiderte Messing-Blechstanzen IC-Anschlussrahmenblätter für PCB-Anwendungen sind hochpräzise Komponenten, die für den Einsatz in integrierten Schaltungen (ICs) für elektronische Geräte entwickelt wurden, insbesondere für solche, die zuverlässige, hochleitfähige Verbindungen erfordern. Sie werden aus hochwertigem Messing und mit hoher Präzision hergestellt. Metallstempeln Prozesse, diese Gehäuse sorgen für optimale elektrische und thermische Leitfähigkeit, die für die Leistung von Leiterplatten in verschiedenen Anwendungen entscheidend ist. Unsere fortschrittlichen Stanztechniken bieten Mikron-genaue Präzision, um die spezifischen Anforderungen der Elektronikindustrie zu erfüllen und eine konsistente Qualität und Leistung über eine Vielzahl von Geräten hinweg sicherzustellen. Darüber hinaus bieten wir vollständig maßgeschneiderte Lösungen an, von Design und Prototyping bis hin zur Produktion, um sicherzustellen, dass jedes Gehäuse den genauen Kundenspezifikationen hinsichtlich Größe, Form und Oberflächenfinish entspricht.

Merkmale:

| Parameter | Value |

|---|---|

| Ursprungsort | Xiamen, China |

| Markenname | OEM |

| Material | Messing |

| Anwendung | PCB-Anwendungen |

| Dienstleistung | Angepasste OEM |

| Oberflächenbehandlung | Verfügbar |

| Größe | Maßgeschneiderte Größe |

| Toleranz | ±0,1 mm |

| MOQ | Kleinaufträge werden angenommen. |

| Farbe | Angepasste Farbe |

| Beispiel | Verfügbar |

| Zertifizierungen | ISO, IATF 16949 |

Oberflächenbehandlungsoptionen:

- Elektroless Nickelbeschichtung: Bietet hervorragenden Verschleiß-, Korrosions- und Lötdurchlässigkeitswiderstand mit einer gleichmäßigen, pinhole-freien Beschichtung.

- Elektrolytisches Zinnbeschichten: Bietet hervorragende Lötfähigkeit, Oxidationsschutz und eine kosteneffiziente Oberflächenbeschichtung für zuverlässige PCB-Montage.

- Silberbeschichtung: Bietet überlegene elektrische Leitfähigkeit, niedrigen Kontaktwiderstand und verbesserte Korrosionsbeständigkeit für Hochleistungs-IC-Kontakte.

- Goldbeschichtung: Gewährleistet optimalen Korrosionsschutz, ultraniedrigen Kontaktwiderstand und langfristige Stabilität für hochzuverlässige PCB-Anwendungen.

Qualitätssicherung:

Unsere Qualitätskontrolle für maßgefertigte Messing-Stanz-IC-Führungsrahmenblätter umfasst eine strenge Überprüfung der eingehenden Materialien sowie einen mehrstufigen Inspektionsprozess. Wir verwenden fortschrittliche Geräte wie Koordinatenmessgeräte (CMM), optische Profilometer und Mikro-Ohm-Meter, um präzise Maßgenauigkeit und überlegene elektrische Leistung sicherzustellen. Darüber hinaus wird die Umweltzuverlässigkeit mit Hilfe von Salzsprüh- und Thermoschockkammern getestet. Unser Unternehmen ist nach ISO 9001:2015 und IATF 16949 zertifiziert, was die Einhaltung internationaler Standards für Qualität und Zuverlässigkeit gewährleistet.

Warum uns wählen?

- Fabrikpreis: Unsere hauseigenen Fertigungsmöglichkeiten ermöglichen es uns, kosteneffektive Lösungen anzubieten und gleichzeitig eine gleichbleibende Produktqualität zu gewährleisten.

- Strenge Qualitätskontrolle: Zertifiziert nach den Standards ISO 9001:2015 und IATF 16949 garantieren wir absolute Präzision und Zuverlässigkeit durch mehrstufige Prüfprotokolle.

- Umfassende Kundenpartnerschaft: Wir unterstützen Sie in jeder Phase, von der Designberatung bis zum Nachbearbeitungsservice, und gewährleisten eine nahtlose Zusammenarbeit.

- Pünktliche Lieferung: Mit optimierten Produktionsabläufen und einem effizienten Lieferkettenmanagement gewährleisten wir die termingerechte Lieferung selbst für die anspruchsvollsten Zeitpläne.

Fabrikvorführung:

Unser hochmodernes Produktionswerk ist mit fortschrittlichen Technologien ausgestattet, darunter CNC-Bearbeitung, Mirror-EDM und präzise Drahtschneidsysteme, die eine überlegene Genauigkeit bei der Herstellung von Anschlussträgern gewährleisten. Wir nutzen 25 Hochleistungspresse von 25 bis 300 Tonnen sowie spezielle Schweiß-, Polier- und Ultraschallreinigungsgeräte, um gründliche Sauberkeit und ausgezeichnete Oberflächenfinishs sicherzustellen. Mit vollautomatischen Produktionslinien und etablierten Qualitätskontrollverfahren halten wir unsere ISO 9001- und IATF 16949-Zertifizierungen aufrecht, die die höchsten Standards in Bezug auf Zuverlässigkeit, Präzision und Haltbarkeit jedes einzelnen Bauteils garantieren.