Übersicht:

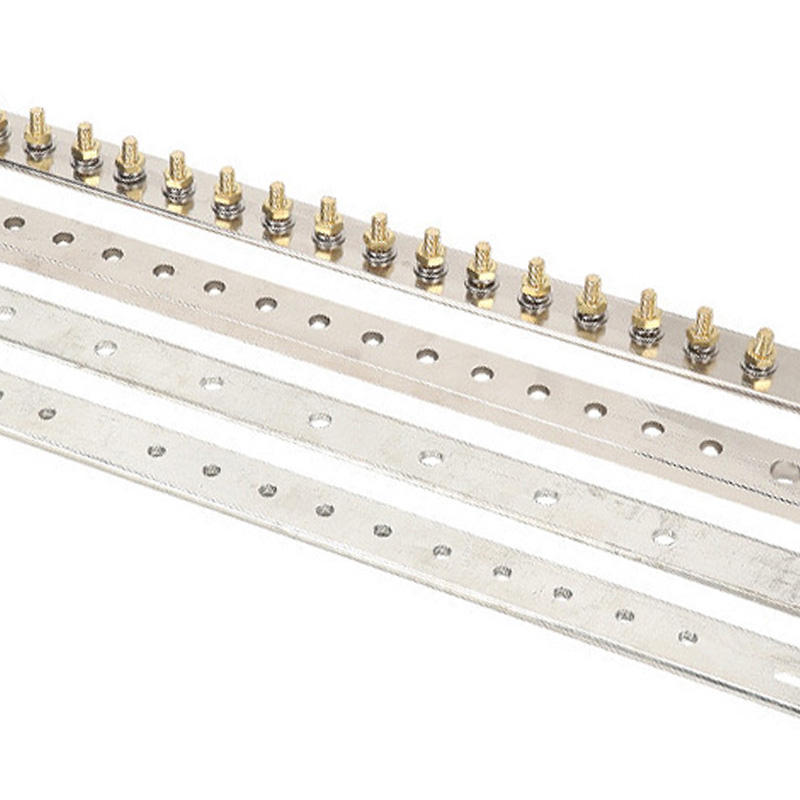

We manufacture custom progressive stamping and machining brass copper busbars designed for high-performance electrical distribution in automotive, energy storage, and industrial power systems. Produced from premium C11000 copper and brass alloys, our busbars deliver outstanding conductivity, mechanical strength, and corrosion resistance. Leveraging advanced progressive die stamping, precision CNC machining, and automated welding processes, we achieve tight dimensional tolerances, consistent geometries, and robust joint integrity.

As a trusted OEM partner, we provide end-to-end solutions, from concept design and rapid prototyping to high-volume production, supported by advanced surface finishing and rigorous electrical and mechanical testing. Our custom busbar solutions optimize electrical efficiency, enhance thermal management, and reduce assembly costs—ensuring long-term system reliability.

Merkmale:

- Ursprungsort: Xiamen, China

- Markenname: OEM

- Material: C11000 Hochleitfähiges Kupfer / Messinglegierungen

- Anpassung: Vollständig unterstützt für Geometrie, Beschichtung und Abmessungen.

- Spezifikation: Standard oder maßgeschneidert gemäß den Anforderungen des Kunden

- Beispiel: Auf Anfrage erhältlich

- Verpackung: Exportstandards oder maßgeschneiderte Verpackungslösungen

- Oberflächenbehandlung: Nickel-, Zinn-, Silber- oder Goldbeschichtung; Anodisierung verfügbar

- Farbe: Individuelle Oberflächen verfügbar

Vorteile unserer Produkte:

- Hohe elektrische Leitfähigkeit – Gewährleistet einen effizienten Stromfluss und minimale Energieverluste.

- Überlegene mechanische Festigkeit – Messing- und Kupferlegierungen bieten hervorragende Haltbarkeit unter mechanischer Belastung.

- Präzisionsformen und -schweißen – Fortschrittliches Stanzen und automatisiertes Schweißen gewährleisten strukturelle Konsistenz und eine lange Lebensdauer.

- Maßgeschneiderte OEM-Engineering – Angepasste Geometrien, Beschichtungen und Baugruppen für eine optimierte Systemintegration.

Oberflächenveredelungsmöglichkeiten:

- Nickelbeschichtung: Korrosionsschutz und stabile elektrische Leistung.

- Zinnbeschichtung: Hervorragende Lötbarkeit und kosteneffektiver Oberflächenschutz.

- Silberbeschichtung: Hohe Leitfähigkeit und überlegene thermische Leistung für anspruchsvolle Anwendungen.

- Goldbeschichtung: Ausgezeichnete Korrosionsbeständigkeit und langfristige Oberflächenstabilität.

- Galvanisierung & maßgeschneiderte Beschichtungen: Kontrollierte Dicke und Oberflächenfinish gemäß den Kundenanforderungen.

Qualitätssicherung:

Unsere progressiv gestanzten Kupfer-/Messing-Busbars mit Schweißdienstleistungen durchlaufen umfassende Tests und Validierungen gemäß den Qualitätsrahmenwerken ISO 9001 und IATF 16949. Rohkupfer und Messinglegierungen werden durch Röntgenfluoreszenz (XRF) Spektrometrie auf Reinheit und Zusammensetzung überprüft. Das progressive Stanzen erfolgt mit CNC-gesteuerten Pressen, die mit Lastüberwachungssystemen ausgestattet sind, um eine wiederholbare Präzision sicherzustellen. Nach dem Stanzen wird die Schweißqualität durch zerstörungsfreie Prüfmethoden (NDT) wie Ultraschallinspektion und metallographische Analysen validiert. Die Maßgenauigkeit wird mit Koordinatenmessmaschinen (CMM) von Zeiss und 3D-Optikscannern bestätigt. Oberflächenbearbeitung und Beschichtungsdicke werden mit XRF-Analysatoren und Profilometern überprüft. Die elektrische Leitfähigkeit wird mit Vierpunkt-Probenprüfern validiert, während Zug- und Streckgrenze mit universellen Prüfmaschinen bewertet werden. Die Rückverfolgbarkeit wird durch seriennummerierte Chargencodes gewährleistet, und alle Materialien entsprechen den RoHS- und REACH-Normen, was Sicherheit und Nachhaltigkeit gewährleistet.

Unsere moderne Produktionsstätte ist mit hochmodernen Maschinen ausgestattet, um die höchste Präzision und Effizienz bei der Herstellung von IC-Leitrahmen zu gewährleisten. Wir betreiben hochtonnage-progressive Stanzpressen sowie präzise Draht-EDM-Maschinen, CNC-Schleifwerkzeuge und Lasermarkierungssysteme. Unsere Beschichtungsmöglichkeiten umfassen Galvanik, Nickelbeschichtung und Goldbeschichtung, sodass wir gleichmäßige und hochwertige Oberflächen für all unsere Produkte liefern können. Darüber hinaus sorgen unsere strengen Qualitätskontrollprozesse, die ISO 9001- und IATF 16949-Zertifizierungen sowie automatisierte Inspektionssysteme dafür, dass jede Charge von Leitrahmen die höchsten Branchenstandards für Leistung und Haltbarkeit erfüllt.

Our facility is equipped with 30 high-speed progressive stamping presses (25–400 tons), precision wire EDM machines, automated welding stations (TIG, MIG, and laser welding), and advanced surface-finishing equipment. Specialized assembly lines enable the integration of complex welded busbar assemblies for EV battery packs, renewable energy systems, and industrial control applications.

We offer in-house electroplating and anodizing services, including nickel, tin, silver, and gold finishes, ensuring durability and performance. Backed by ISO 9001 and IATF 16949 certifications, our factory maintains strict quality management systems, supported by 3D inspection systems, sealing testers, durometers, and microhardness testers.

With automated production lines, Class 8 cleanroom environments, and skilled engineering teams, we deliver high-precision, reliable, and scalable busbar solutions that meet the most demanding global standards.