If you’re uncertain about which stempeln process to choose for your metal parts, you’re not alone. Choosing the wrong method can lead to wasted time, increased costs, and complications down the line. Whether you’re developing a new product or scaling up production, understanding the nuances of short-run versus mass production metal stamping is crucial. This blog will help clarify when each method is most appropriate, saving you time and money while ensuring that your parts meet the desired quality standards.

At Plantmetal, we specialize in providing OEM services tailored to your specific needs. As a leading manufacturer and supplier in China, we understand the intricacies of choosing the right manufacturing process for your products. Let’s dive into the details of short-run and mass production metal stamping, so you can make an informed decision for your next project.

What is Short Run Stamping?

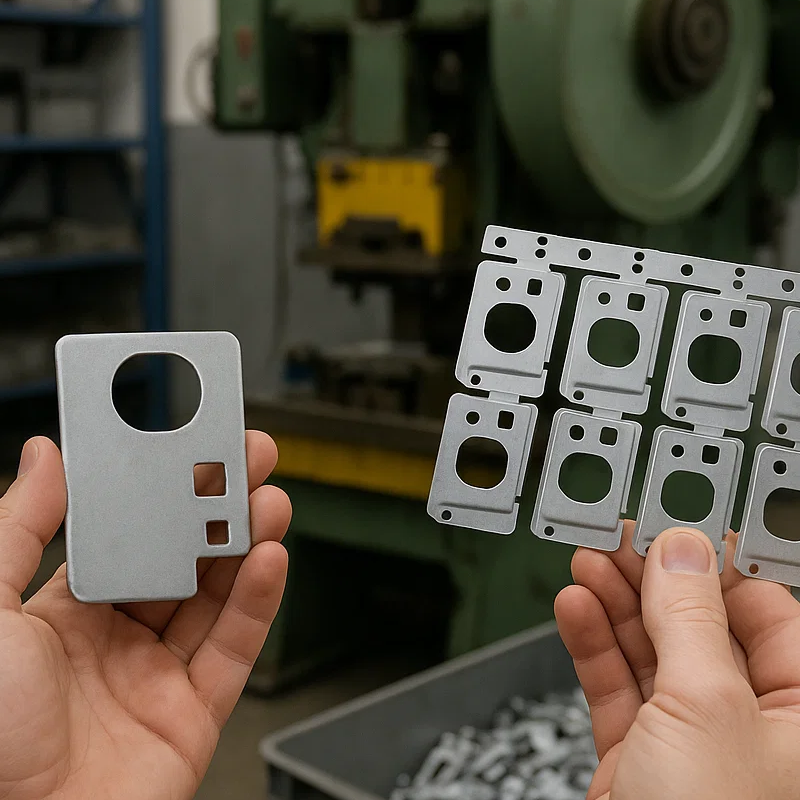

Short-run stamping is an efficient method for low-volume production, such as prototypes or limited orders. This approach is ideal when you’re testing a new design or need fewer parts to get your product to market. The main advantage of short-run stamping lies in its cost-effective tooling setup, which makes it a great option for smaller production runs. In short-run stamping, we use simpler tooling to perform individual operations on the metal sheets, such as cutting, bending, and punching.

What is Mass Production Stamping?

Mass production stamping, on the other hand, is designed for high-volume manufacturing. This method uses progressive die stamping, where a single die performs multiple operations in sequence to create a finished part. This is ideal when producing large quantities of complex parts with tight tolerances. The efficiency of progressive die stamping allows for high-speed production, reducing labor costs and cycle times.

At Plantmetal, we can handle both short-run and mass production metal stamping. Our experience in both methods allows us to offer flexible solutions for your production needs, whether you’re scaling up or just starting with a small batch.

When Should You Choose Short Run Stamping?

Short-run stamping is the best option when you need a smaller quantity of parts or prototypes. If you’re testing a new design or working within a limited budget, this method can save you a significant amount on tooling costs. Short-run stamping is particularly useful when:

- You need to produce fewer than 10,000 parts.

- The part design is still in its experimental or testing phase.

- You want to minimize initial tooling investment.

- The parts are less complex and don’t require intricate features.

While short-run stamping does have slower cycle times and higher labor costs per part compared to mass production, it allows you to get your product to market quickly and at a lower upfront cost. At Plantmetal, we help streamline the short-run stamping process with customized solutions, so you can test your products and adjust designs without the burden of large-scale investments.

When Should You Choose Mass Production Stamping?

Mass production stamping is ideal when you need high volumes of identical parts, especially if the parts have complex geometries and tight tolerances. This method is particularly beneficial when:

- You need to produce thousands or even millions of parts.

- Your design involves intricate features that must be manufactured with precision.

- The cost per part needs to be reduced by distributing tooling costs over a large number of units.

For instance, automotive components like brackets, clips, and retainers are often produced using mass production stamping methods. At Plantmetal, our progressive die stamping services are designed to handle high-volume production with minimal variation between parts, ensuring that your production runs smoothly, quickly, and economically.

Comparing the Four Main Types of Metal Stamping

Understanding the different types of metal stamping helps determine the most appropriate process for your specific needs. Here’s a breakdown of the four main types of metal stamping:

| Stamping Type | Best for | Part Complexity | Tooling Cost | Common Applications |

|---|---|---|---|---|

| Progressivwerkzeug | High-volume production | Hoch | Hoch | Terminals, shields, clips |

| Fourslide | Medium-high production | High (bends) | Medium | Clips, flat springs, wire forms |

| Deep Draw | Medium-high production | Low (hollow) | Medium-high | Cans, cups, enclosures |

| Short Run | Low-volume orders | Low-medium | Low | Prototypes, brackets |

Key Differences Between Short Run and Mass Production Stamping

The choice between short-run and mass production stamping comes down to a few key factors:

- Volume: If you’re producing fewer parts, short-run stamping makes sense. But for high volumes, mass production stamping is more efficient and cost-effective.

- Part Complexity: For parts with intricate designs or multiple operations, mass production with progressive die stamping is your best option.

- Tooling Investment: Short-run stamping has lower tooling costs, making it suitable for small orders or prototypes. Mass production requires a larger initial investment but yields better cost per part when producing large quantities.

- Cycle Time: Mass production stamping has faster cycle times, which is ideal for high-volume production.

Common Challenges and How to Overcome Them

While stamping is an efficient method for producing parts, there are challenges to consider:

- Material Properties: Not all metals are suitable for stamping, especially if they are too thick or too thin. We at Plantmetal ensure that your parts are produced with materials that are optimal for your design.

- Design Complexity: Parts with undercuts or intricate 3D features are difficult to stamp using conventional methods. Our engineering team at Plantmetal works closely with you to find the most effective solution, whether it’s through progressive die stamping or fourslide stamping.

- Tooling Costs: Progressive die tooling can be expensive. However, at Plantmetal, we aim to keep costs manageable while still delivering high-quality results for high-volume production runs.

How to Choose the Right Method for Your Project

Choosing between short-run and mass production stamping depends on several key factors, such as your project’s complexity, volume, budget, and timeline. At Plantmetal, we offer OEM services and a one-stop service to help guide you through every step of the process. Our experienced engineers will help you decide which method will best meet your needs, ensuring that you make the most efficient and cost-effective decision.

If you’re unsure about which process to choose for your project, feel free to reach out to us. Our team is ready to help you make the best decision based on your specific requirements, ensuring a successful manufacturing experience from start to finish.

Conclusion

Deciding between short-run and mass production metal stamping is a crucial decision that will affect both the quality and cost of your parts. Whether you’re producing a small batch for prototyping or ramping up for large-scale production, Plantmetal is here to help. We offer customized solutions, high-quality manufacturing, and expert guidance to ensure you get the best results.Contact us today to discuss your project and get a customized quote. Let’s work together to make your vision a reality.