Resumen

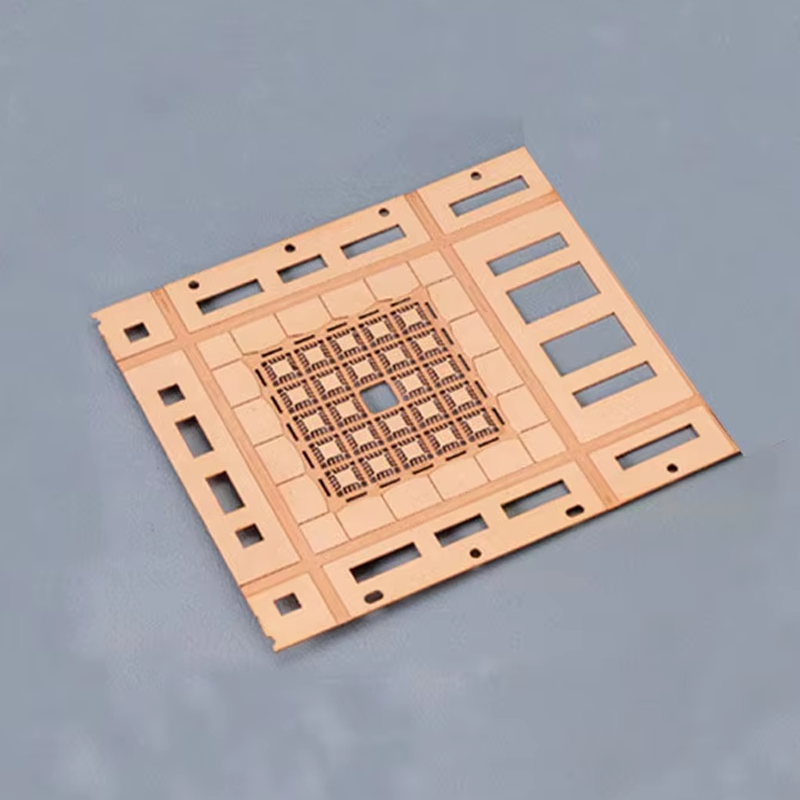

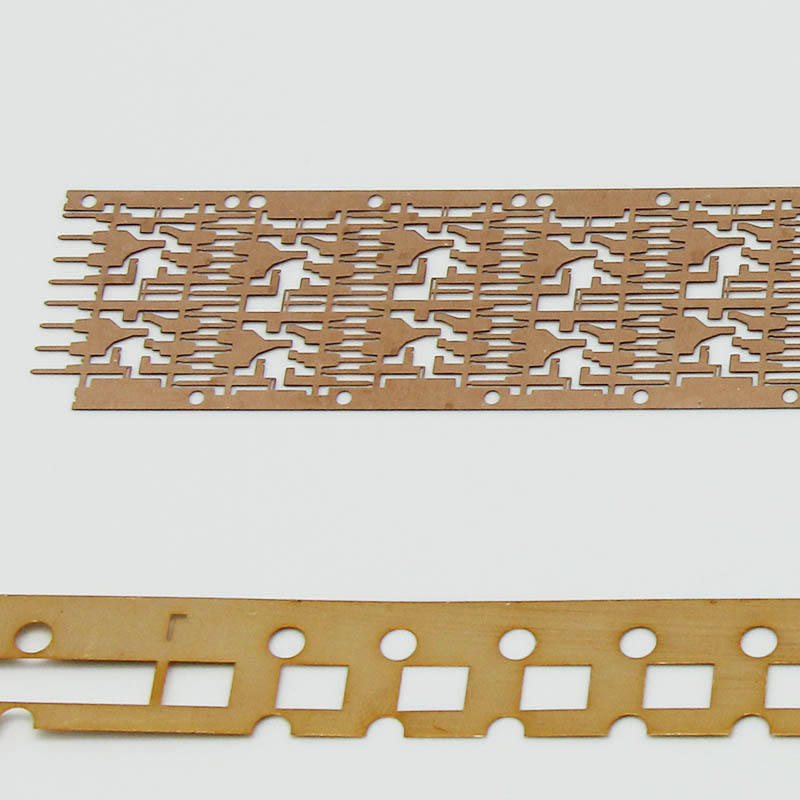

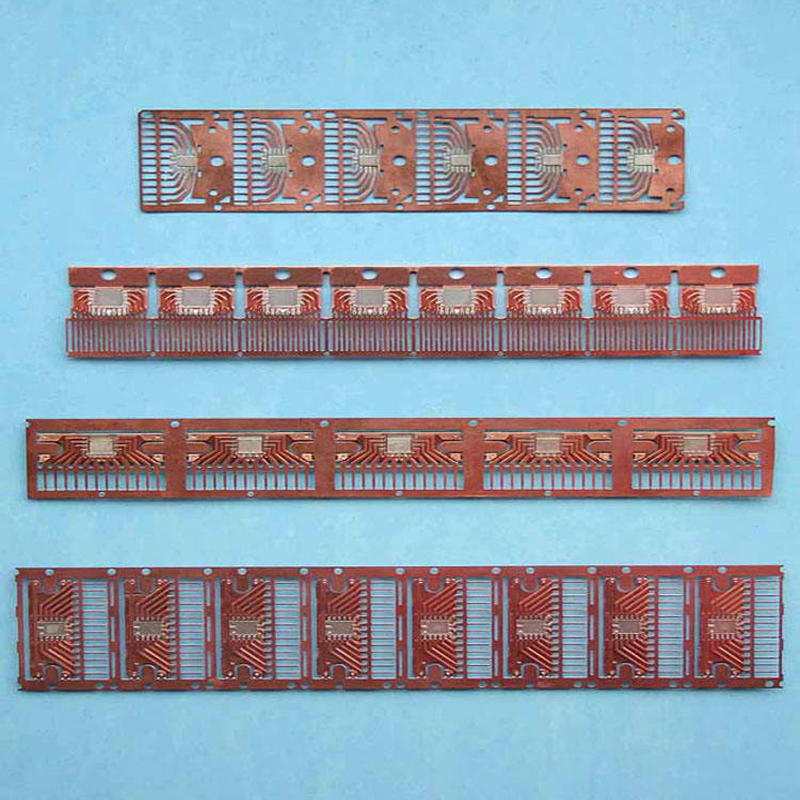

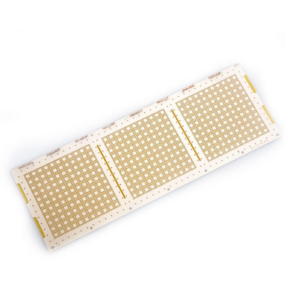

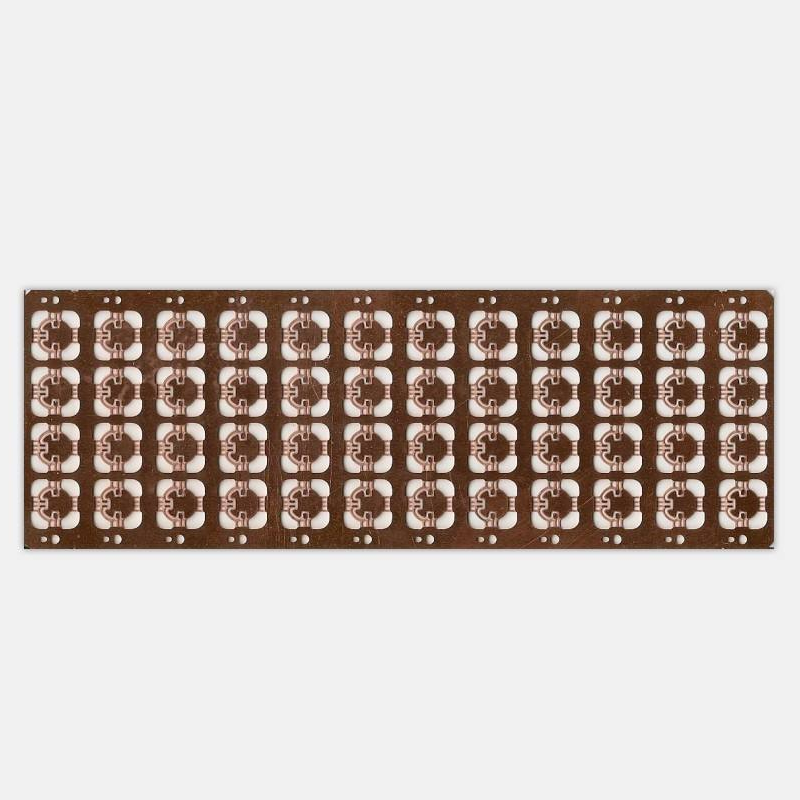

Nos especializamos en la fabricación de marcos de microconexiones de cobre y latón para grabado láser de alta precisión, diseñados para su uso en una variedad de aplicaciones electrónicas, incluidos circuitos integrados (ICs) y semiconductores. Nuestros marcos de conexión se producen utilizando tecnología avanzada de grabado láser que garantiza una precisión superior y un detalle fino para componentes micro. Fabricados con aleaciones de cobre y latón de alta calidad, nuestros marcos de conexión ofrecen una excelente conductividad eléctrica, rendimiento térmico y resistencia a la corrosión.

Nuestro proceso de fabricación utiliza estampado de precisión, grabado láser y mecanizado CNC para cumplir con tolerancias estrictas, garantizando productos de alta calidad y consistentes. También ofrecemos opciones adicionales de plating en metal, como níquel, estaño y oro, para mejorar la durabilidad y funcionalidad de los marcos de conexión. Como socio OEM confiable, ofrecemos soluciones personalizadas para satisfacer requisitos específicos, proporcionando todo, desde prototipos hasta producción en masa.

Nuestro compromiso con la calidad y la innovación garantiza que nuestros marcos de conexión optimicen sus diseños electrónicos, reduzcan los costos de ensamblaje y mejoren el rendimiento general del sistema. Contáctenos hoy para explorar cómo nuestros marcos de conexión diseñados a medida pueden satisfacer sus necesidades únicas.

Características

| Función | Detalles |

|---|---|

| Lugar de origen | Xiamen, China |

| Nombre de la Marca | OEM |

| Material | Cobre, Latón, Aleaciones de Alta Conductividad |

| Personalización | Disponible (tamaños, formas, colores y logotipos) |

| Muestra | Proporcionado a petición. |

| Especificación | Estándar o personalizado según las necesidades del cliente. |

| Embalaje | Embalaje estándar para exportación o embalaje personalizado. |

| Color | Personalizable |

| Opciones de Plating | Niquel, Estaño, Oro, Plata |

| Plazo de Entrega | 20–25 días hábiles |

Beneficios de Nuestros Marcos de Plomo

-

Alta Precisión: La tecnología de grabado láser garantiza que los micro marcos de plomo se fabriquen con la máxima precisión para aplicaciones electrónicas exigentes.

-

Conductividad Superior: Se eligen materiales de cobre y latón por su excelente conductividad eléctrica y térmica, lo que garantiza un rendimiento fiable en componentes electrónicos.

-

Opciones de personalización: Ofrecemos tamaños, formas y colores personalizados para satisfacer sus especificaciones únicas, junto con servicios de impresión de logotipos para mejorar la identidad de marca.

-

Resistencia a la corrosión: Con acabados superficiales opcionales como el niquelado o el dorado, nuestros marcos de conexión ofrecen una protección superior contra factores ambientales, prolongando la vida útil del producto.

Opciones de Acabado de Superficie

-

Niquelado: Proporciona una mayor resistencia a la corrosión, una mejor protección contra el desgaste y una conductividad eléctrica fiable.

-

Estaño Galvanizado: Excelente soldabilidad, resistencia a la corrosión y protección rentable para componentes electrónicos sensibles.

-

Baño de oro: Proporciona una superior resistencia a la corrosión y una excelente conductividad para aplicaciones de alto rendimiento.

-

Plata en baquelita: Ideal para aplicaciones que requieren una superior conductividad eléctrica y rendimiento térmico.

-

Electrodeposición: Acabado de metales controlado con precisión disponible en diversos recubrimientos, diseñado para cumplir con requisitos específicos de rendimiento y durabilidad.

Aseguramiento de la Calidad

Nuestros marcos de microconexiones de cobre y latón grabados con láser OEM pasan por un riguroso proceso de aseguramiento de la calidad que se adhiere a las normas ISO 9001 e IATF 16949. El proceso comienza con la selección de materiales de primera calidad, verificados mediante espectrometría de fluorescencia de rayos X (XRF). Utilizamos prensas de estampado de precisión y tecnología de grabado láser para producir componentes que cumplen con las tolerancias más estrictas. La precisión dimensional y la conformidad geométrica se confirman utilizando máquinas de medición por coordenadas (CMM) de Zeiss y escáneres láser 3D. El grosor del recubrimiento se mide cuidadosamente a través de XRF y perfilómetros ópticos para garantizar una calidad consistente. También realizamos pruebas exhaustivas de conductividad eléctrica con un medidor de cuatro puntas, y las propiedades mecánicas se prueban utilizando máquinas de ensayo universal. Nuestros productos cumplen con las normas RoHS y REACH, y garantizamos la trazabilidad a través de la codificación de lotes seriados. Además, todos los productos cumplen con los requisitos de seguridad UL 486 para aplicaciones de alta tensión.

Nuestra fábrica

Our cutting-edge manufacturing facility is equipped with 25 high-performance punch presses ranging from 25–300 tons, along with precision wire EDM machines and advanced grinding systems. These capabilities ensure exceptional precision and high-quality output. We offer a wide range of metal-plating options, including nickel, chrome, gold, and silver plating, applied through advanced electroplating processes. Our facility also includes specialized welding, polishing, and ultrasonic cleaning stations to guarantee the best surface finishes. All production lines are fully automated and governed by ISO 9001 and IATF 16949 certifications, ensuring high standards of performance, quality, and consistency.Contact us today to learn how our precision-engineered copper brass lead frames can enhance your electronic designs and improve performance!