Resumen

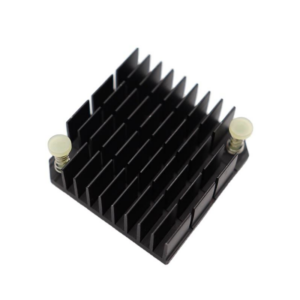

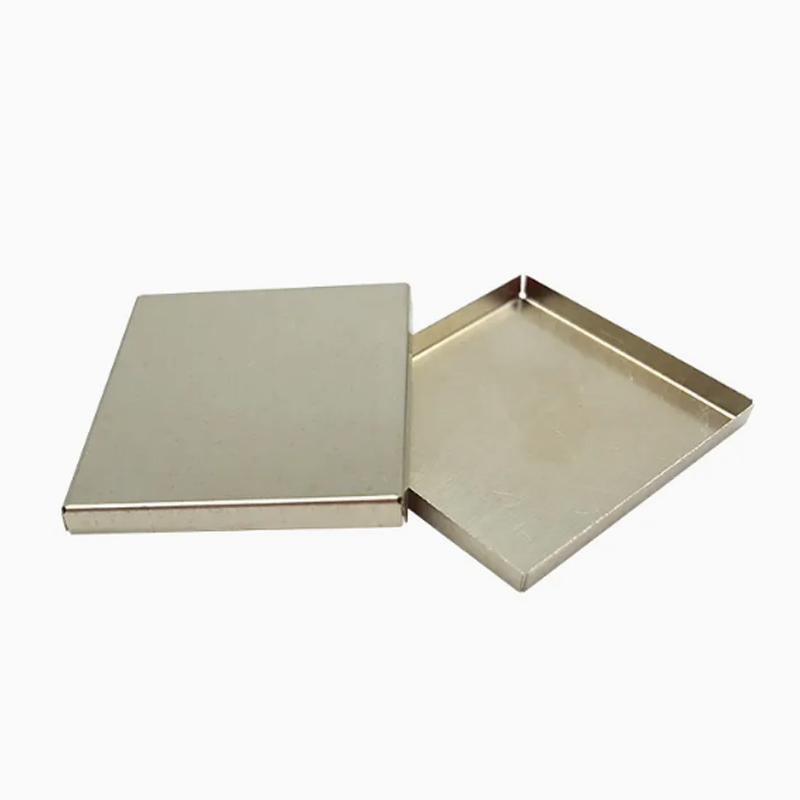

Nuestras cubiertas de protección de acero inoxidable con recubrimiento electrolítico personalizadas, fabricadas mediante un proceso de embutición profunda, están diseñadas para proporcionar una robusta protección contra EMI/RFI, protección mecánica y un acabado resistente a la corrosión para circuitos impresos en electrónica industrial, de telecomunicaciones, médica y aeroespacial. Fabricadas con aceros inoxidables de primera calidad (SUS301 / SUS304 / SUS316L) utilizando técnicas de embutición profunda de precisión y estampado progresivo, cada cubierta de protección se termina con una capa uniforme de recubrimiento electrolítico (e-coat) que ofrece una excelente resistencia a la corrosión, propiedades dieléctricas consistentes y una superficie preparada para recubrimientos secundarios o juntas. Ofrecemos servicios OEM integrales: herramientas, prototipos, producción en alta cantidad, mecanizado secundario, ensamblaje y un estricto control de calidad, para proporcionar soluciones de blindaje optimizadas para aplicaciones que cumplen con los requisitos eléctricos, mecánicos y medioambientales.

Características

| Atributo | Detalles |

|---|---|

| Lugar de origen | Xiamen, China |

| Marca | Marca blanca / OEM |

| Material base | Acero inoxidable SUS301 / SUS304 / SUS316L (otras aleaciones bajo petición) |

| Grosor del material | 0,3 – 3,0 mm (personalizable) |

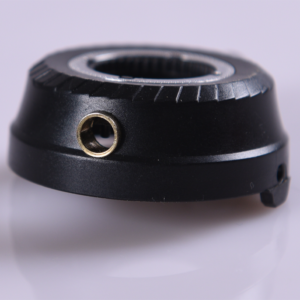

| Proceso | Profundidad de embutición - Estampado progresivo - Corte por láser - Doblado/formado CNC - Doblez de borde - Soldadura por puntos |

| Recubrimiento Electrofórico | E-coat (deposición electroforética), grosor típico de 5 a 25 μm. |

| Color / Acabado del Recubrimiento | Acabado mate / satinado estándar; disponibles acabados personalizados en RAL o texturizados. |

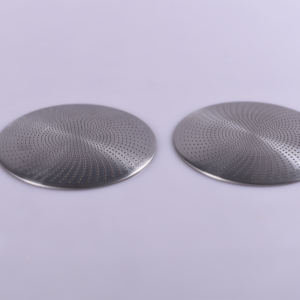

| Efectividad de Apantallamiento | Típico de 40 a 80 dB (dependiendo de la aplicación; hasta más de 80 dB con ensamblajes con juntas/sellados) |

| Tolerancia | ±0,01 mm (áreas funcionales; tolerancia general ±0,05 mm) |

| Tratamiento de Superficie | Pasivación, electropulido, chorreado de perlas o tratamientos posteriores personalizados. |

| Certificación | ISO 9001:2015, IATF 16949 (opcional), RoHS, REACH |

| Muestra de Tiempo de Entrega | 5–10 días hábiles (pieza de prototipo estampada) |

| El tiempo de producción | 15–35 días hábiles (dependiendo de la herramienta) |

| MOQ | Flexible; prototipado a volumen alto soportado |

| Embalaje | Envoltura anticorrosiva, soportes de espuma, kits personalizados para ensamblaje. |

Manufactura y Procesos

- Herramientas y Formado: Los troqueles progresivos y las herramientas de embutición fabricados internamente a través de mecanizado CNC y EDM por hilo/espejo garantizan un formado repetible, flanges ajustados y radios limpios para el ajuste de PCB.

- Metalurgia: estampado progresivo a alta velocidad, corte láser de troqueles, plegado CNC y embutición controlada en profundidad para preservar la estructura del material y las propiedades de recuperación elástica.

- Unión y Montaje: Soldadura por puntos de precisión, soldadura TIG, soldadura láser y clinchado para costuras o características de montaje integradas. Doblez y flangedo para bordes seguros para el usuario y superficies de acoplamiento robustas.

- Preparación de Superficie y E-Capa: Las piezas reciben una limpieza y pretratamiento en múltiples etapas (lavado alcalino, desoxidación). La deposición electroforética (E-capa) produce recubrimientos uniformes y conformes en geometrías complejas; se curan en hornos controlados hasta alcanzar el grosor de película especificado.

- Acabados secundarios: Pulido electrolítico opcional, pasivación o recubrimiento en polvo sobre recubrimiento electrostático donde se requiera una mayor estética o resistencia química. Se encuentran disponibles ranuras para juntas, aplicación de pintura conductiva o epoxi de plata, e integración de juntas RF.

Opciones de Tratamiento de Superficie y Recubrimiento

- Recubrimiento electroforético (E-Coat): Protección uniforme contra la corrosión; excelente base para recubrimientos posteriores; grosor típico de 5–25 μm.

- Electropulido: Reduce la rugosidad de la superficie, mejora la resistencia a la corrosión y la integridad del contacto donde se requiere contacto metal con metal.

- Pasivación (Nítrica / Cítrica): Restaura la capa de óxido de cromo del acero inoxidable para mejorar la resistencia a la corrosión.

- Recubrimientos conductores / Galvanoplastia selectiva: Galvanoplastia selectiva de plata o níquel para mejorar la conductividad de contacto en superficies de juntas o de acoplamiento.

- Acabado en polvo / Capas de poliéster: Acabados decorativos resistentes a la intemperie sobre e-coat para aplicaciones al aire libre o estéticas.

- Integración de juntas personalizadas / juntas EMI: Integración de silicona, espuma conductiva o dedos de resorte para ensamblajes de alta SE.

Rendimiento Eléctrico y Mecánico

- Efectividad de Apantallamiento (SE): Diseñado y verificado para una SE objetivo utilizando mediciones de laboratorio; rendimiento típico de 40 a 80 dB en el rango de 100 kHz a 6 GHz, dependiendo del diseño, las costuras y los sellos. Validación de SE según los requisitos del cliente (IEEE 299, MIL-STD-285, o equivalente disponible).

- Integridad Mecánica: La geometría de embutición profunda proporciona una alta relación de rigidez a peso y una tensión de resorte repetible para ensamblajes montados a presión o con tornillos.

- Térmico y Medioambiental: El recubrimiento electrostático junto con la construcción en acero inoxidable soporta amplios rangos de temperatura y resiste la humedad, la pulverización de sal y los agentes de limpieza comunes.

Aseguramiento de la Calidad

Aplicamos un programa de aseguramiento de calidad riguroso en el control de materiales, herramientas, producción e inspección final.

- Inspección de entrada: Verificación química y mecánica (certificados de material, dureza y grosor).

- Control Dimensional: CMM, escaneo óptico 2D/3D y monitorización SPC para garantizar la forma, la posición de los agujeros y las tolerancias críticas.

- Pruebas de recubrimientos y superficies: medición del grosor de la película (XRF / corriente de Eddy), pruebas de adhesión (malla cruzada), pruebas de corrosión por rocío salino (ASTM B117) y comprobaciones de brillo/apariencia.

- Pruebas eléctricas: validación de la efectividad del apantallamiento, verificación de la resistencia de contacto en las superficies de acoplamiento y pruebas de continuidad cuando sea aplicable.

- Trazabilidad del Proceso: Codificación de lotes serializados, informes de Inspección del Primer Artículo (FAI), indexación de capacidad del proceso (Cp/Cpk) en dimensiones críticas.

Aplicaciones

- Latas y cubiertas de apantallamiento EMI/RFI para PCB para: estaciones base de telecomunicaciones, routers, electrónica médica, controladores industriales, ECU automotrices, aviónica aeroespacial y instrumentación de precisión.

- Recintos y particiones internas que requieren tanto blindaje electromagnético como protección mecánica.

Perfil de la fábrica: La fábrica se dedica a la producción de componentes de alta calidad para la industria automotriz, utilizando tecnología avanzada y prácticas sostenibles. Con un equipo de profesionales altamente capacitados, garantizamos la eficiencia en nuestros procesos y un compromiso constante con la innovación. Nuestra ubicación estratégica nos permite distribuir nuestros productos de manera efectiva, asegurando que cumplamos con las demandas del mercado. Además, estamos comprometidos con la responsabilidad social y el bienestar de nuestros empleados, creando un entorno de trabajo seguro y colaborativo.

Nuestra instalación combina experiencia en conformado de metales de precisión y acabado superficial para ofrecer soluciones completas de apantallamiento: sala de herramientas para la fabricación de matrices progresivas y de embutición profunda (CNC, EDM, WEDM), prensas progresivas de varias toneladas y prensas de embutición profunda, líneas de corte por láser y plegado CNC, celdas automatizadas de soldadura por puntos/láser y líneas dedicadas de recubrimiento electrostático con hornos de curado controlados. El post-procesamiento incluye electropulido, pasivación, análisis de recubrimiento por XRF y una capacidad interna de prueba EMI para la verificación del apantallamiento. Los flujos de trabajo alineados con ISO 9001 e IATF, el monitoreo SPC y la trazabilidad completa de materiales aseguran piezas consistentes y listas para la producción, desde prototipos hasta series de alta producción.