Are you tired of dealing with messy cuts, wasted material, or inconsistent quality when working with stainless steel? At Plantmetal, we’ve seen many clients frustrated with traditional cutting methods that fail to deliver the precision and efficiency they need. That’s exactly why we’ve invested heavily in advanced fiber laser technology and positioned ourselves as a trusted factory and OEM service supplier for global customers. In this blog, we’ll walk you through everything you need to know about laser cutting stainless steel—from the science behind it, to the best practices, to why partnering with experienced manufacturers like us ensures consistent, high-quality results.

What Makes Stainless Steel Unique?

Stainless steel isn’t just another alloy—it’s a material that demands specialized handling. Containing at least 10.5% chromium, stainless steel forms a natural, self-healing chromium oxide layer that protects it from rust and corrosion. This unique property makes it the backbone of industries ranging from medical devices to kitchenware, aerospace, and construction.

But not all stainless steels are the same. At Plantmetal, we work with a variety of grades, each serving different purposes:

- Austenitic (304, 316): The most common family, offering exceptional corrosion resistance and excellent formability. Perfect for food processing and medical applications.

- Ferritic (430): Magnetic and cost-effective, often used in appliances and decorative parts.

- Martensitic (410, 420): Extremely hard and strong, ideal for tools and high-wear components.

Choosing the right grade is critical for any fabrication project. As an experienced factory supplier, we help clients select materials that balance durability, cost, and performance.

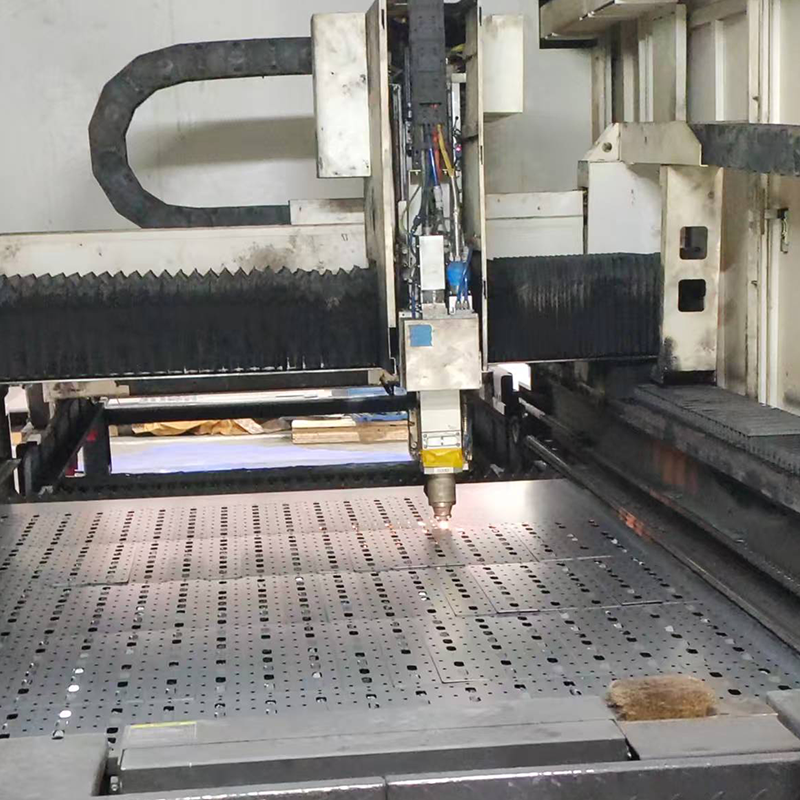

How Laser Cutting Stainless Steel Works

At first glance, it sounds unbelievable—a concentrated beam of light slicing through solid steel. Yet in practice, laser cutting is one of the most reliable, high-precision manufacturing processes available today.

Here’s how it works:

- Laser Beam Focused on Surface – A fiber laser concentrates immense energy on a pinpoint area of the stainless steel.

- Localized Melting and Vaporization – The heat melts or vaporizes the metal instantly.

- Assist Gas Removes Molten Material – High-pressure nitrogen or oxygen clears away the molten metal, leaving a smooth, clean edge.

At Plantmetal, we almost always use high-pressure nitrogen for stainless steel. Unlike oxygen, nitrogen prevents oxidation, resulting in a bright, burr-free finish that requires little to no secondary processing. This is one of the biggest value-adds we deliver to our OEM customers—parts that are production-ready straight from the cutting table.

Why Manufacturers Choose Fiber Laser Technology

There are several ways to cut stainless steel—waterjet, plasma, mechanical punching—but none compare to fiber laser technology in terms of speed, precision, and consistency. That’s why leading manufacturers and suppliers across industries have shifted to laser cutting as their standard.

Compared to older CO2 lasers, fiber lasers have significant advantages:

- Superior Efficiency – Fiber lasers operate at a wavelength (1 µm) that stainless steel absorbs much more effectively.

- Higher Cutting Speeds – Especially efficient for thin-to-medium sheets, drastically reducing lead times.

- Lower Operating Costs – No mirrors to align, less maintenance, and reduced energy consumption.

- Exceptional Precision – Achieving tolerances of +/- 0.005 inches, perfect for high-precision OEM parts.

As a factory specializing in stainless steel fabrication, our decision to invest in fiber laser systems was simple: it allows us to provide better quality at a competitive price.

Factors That Define a Perfect Laser Cut

Getting stainless steel laser cutting right isn’t just about owning the right machine—it’s about knowing how to balance the critical variables. At Plantmetal, our engineers calibrate each project with meticulous attention to detail:

- Laser Power: Determines penetration depth. Higher power is used for thick sheets, while lower power prevents warping thin material.

- Cutting Speed: Too slow results in rough edges; too fast leads to incomplete cuts. Experience tells us exactly where the sweet spot is.

- Assist Gas Pressure: Nitrogen is carefully regulated to ensure oxide-free edges without cooling the cut path excessively.

- Focal Position: Precision in focus is key to delivering repeatable results.

This expertise is why suppliers and OEM partners trust our factory for mission-critical applications.

Beyond Cutting: What Else Can Lasers Do?

Many people think lasers are just for cutting shapes out of sheet metal. In reality, the versatility is far greater. With the same equipment, our factory can also:

- Engrave Logos and Markings – Ideal for OEM suppliers who need branding or traceability (e.g., serial numbers, QR codes).

- Etch Surface Patterns – Useful for medical instruments, consumer electronics, or decorative finishes.

- Produce Complex Geometries – From intricate lattice structures to micro-perforations.

This multifunctionality reduces the need for multiple processes, helping our clients save time, cost, and complexity.

Choosing the Right Stainless Steel for Laser Cutting

From thin decorative panels to heavy-duty machine parts, different projects demand different stainless steels. The grades we cut most frequently include:

- 304: The workhorse grade, balancing corrosion resistance and affordability.

- 316: Marine-grade stainless steel, essential for environments exposed to chemicals or saltwater.

- 430: A ferritic option, cost-effective and magnetic, used in appliance housings.

- 301: High strength and ductility, ideal for formed components post-cutting.

As a full-service manufacturer, we don’t just cut steel—we guide customers on selecting the best material for their intended application. That’s part of the value of partnering directly with a factory supplier like Plantmetal.

Expected Results with High-Precision Laser Cutting

When clients partner with Plantmetal for OEM stainless steel parts, they know exactly what to expect:

| Función | Result | Benefit for Customer |

|---|---|---|

| Tolerancia | +/- 0.005” | Perfect fit in assemblies |

| Edge Quality | Smooth, oxide-free | No secondary finishing needed |

| Heat-Affected Zone | Minimal | Preserves strength & corrosion resistance |

| Consistency | High repeatability | Reliable for bulk OEM orders |

This level of high precision is why so many suppliers and manufacturers choose to outsource their stainless steel processing to us rather than investing in expensive in-house equipment.

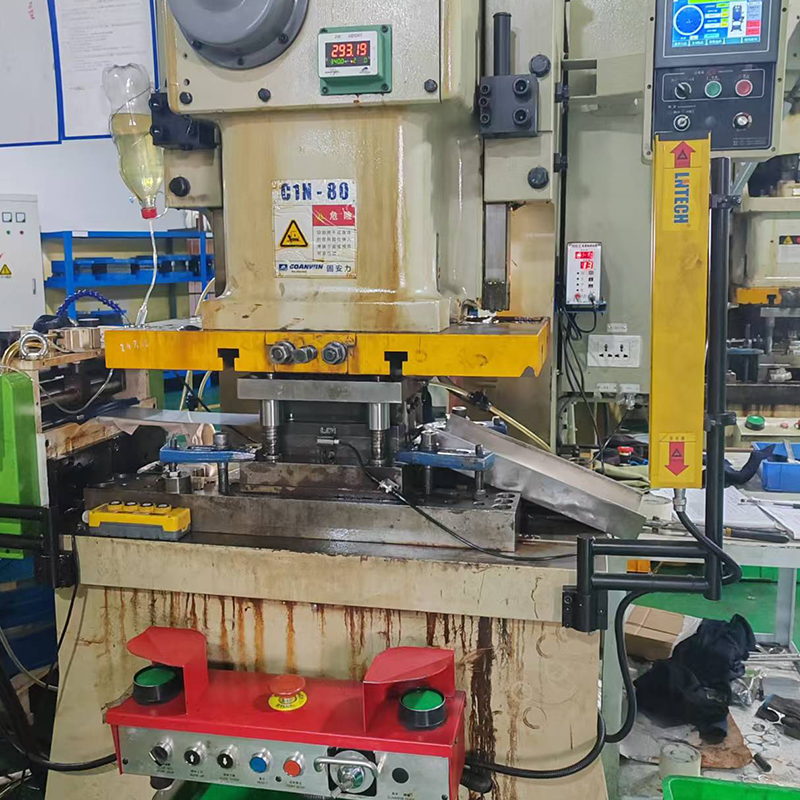

Alternatives to Laser Cutting

It’s true—there are other cutting methods out there. Waterjet, plasma, and punching can all process stainless steel, but each has limitations:

- Waterjet: Excellent for very thick materials, but slower and more expensive per part.

- Plasma: Fast and cheap for thick plate, but poor edge quality.

- Punching: Efficient for simple, repetitive shapes, but unsuitable for complex geometries.

For projects requiring tight tolerances, clean finishes, and scalable OEM service, laser cutting remains the undisputed best choice.

Why Work With Plantmetal?

As a dedicated stainless steel fabrication factory, Plantmetal offers more than just cutting services. We provide a complete solution for global clients who need bulk OEM parts, consistent quality, and reliable suppliers.

Here’s what sets us apart:

- OEM Service: From prototyping to full-scale production, tailored to your needs.

- Factory-Direct Advantage: Competitive pricing with no middlemen.

- Experienced Manufacturers: Decades of expertise in sheet metal and precision cutting.

- Supplier Reliability: ISO-certified processes, rigorous QC, and on-time delivery.

We’ve helped businesses across North America, Europe, and Asia streamline their supply chains by outsourcing stainless steel laser cutting to us. Whether you need small-batch prototypes or bulk OEM orders, our team ensures every part meets your exact specifications.

Conclusion:

Laser cutting stainless steel isn’t just about technology—it’s about experience, precision, and the right manufacturing partner. At Plantmetal, we pride ourselves on being more than just another factory supplier. We are your partner in delivering high-precision OEM stainless steel parts that save you time, reduce waste, and keep your production on schedule.

So, if you’re a business owner, engineer, or procurement manager looking for a reliable partner, why not work with us? Let’s talk about your next project and show you why leading manufacturers and suppliers around the world trust Plantmetal’s factory OEM services for their stainless steel fabrication needs.