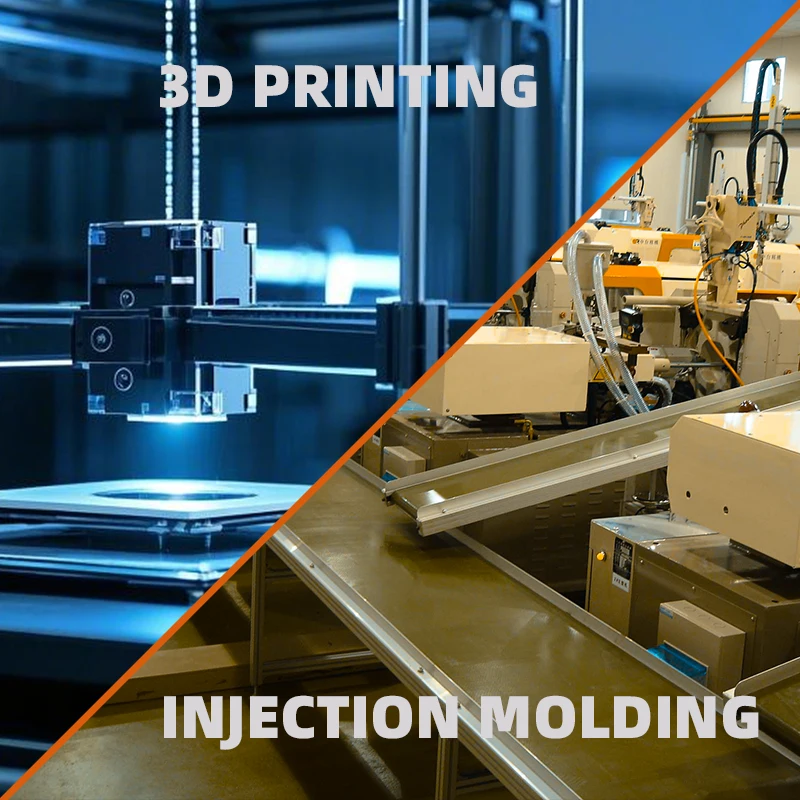

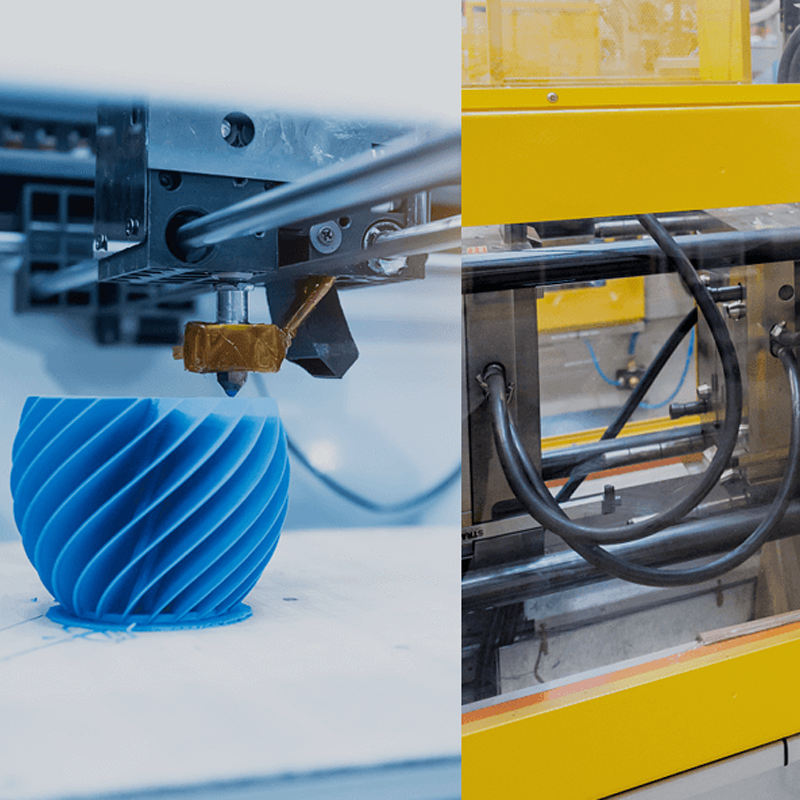

When it comes to selecting the best manufacturing process for producing plastic parts, both 3D printing and injection molding offer distinct advantages. Understanding the differences between the two technologies can help you make the most informed decision for your project, whether you’re working on a prototype, a short production run, or large-scale manufacturing. At Plantmetal, a leading manufacturer offering a one-stop service, we specialize in both processes and are here to guide you through their strengths, limitations, and the most suitable applications.

What is 3D Printing?

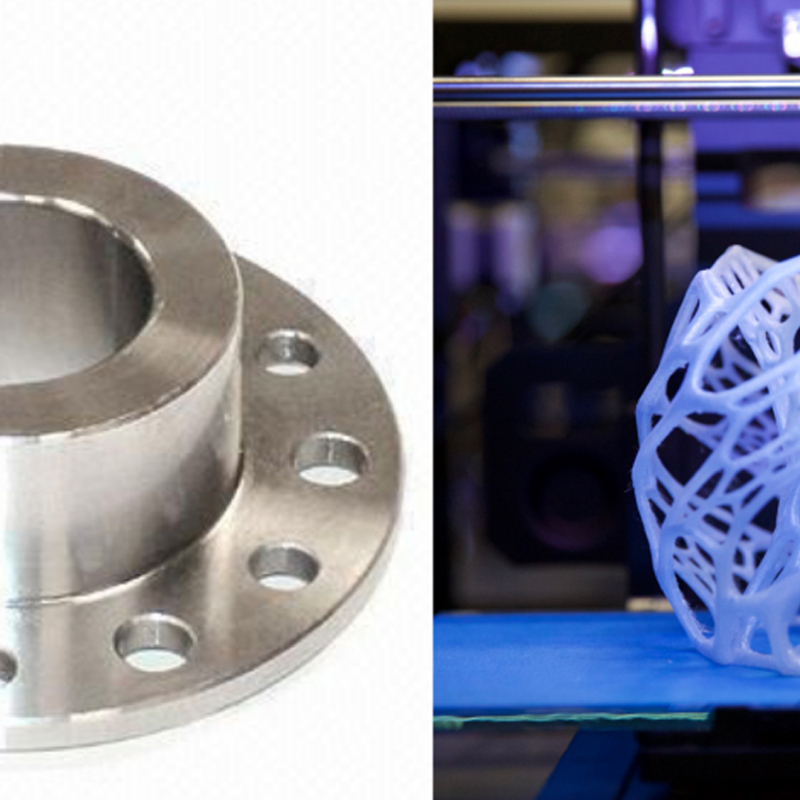

3D printing, also known as additive manufacturing, is a revolutionary process that builds parts layer by layer from a digital file. It is primarily used for prototyping, design iterations, and low-volume production runs. Unlike traditional manufacturing, 3D printing does not require molds or tooling, making it an ideal option for complex geometries, customization, and rapid design validation.

The most commonly used 3D printing methods include:

- FDM (Fused Deposition Modeling): This process melts thermoplastic filament and deposits it layer by layer, making it ideal for cost-effective prototypes and small production runs.

- SLA (Stereolithography): Using a laser to cure liquid resin layer by layer, SLA offers precise, high-resolution prints suitable for detailed components.

- SLS (Selective Laser Sintering): This method uses a laser to fuse powdered material into solid layers, ideal for producing functional, durable parts.

- DLP (Digital Light Processing): Similar to SLA, but uses a digital projector to cure the resin faster, offering high-quality prints with smooth surface finishes.

Each of these techniques offers unique advantages depending on the project’s complexity, material requirements, and desired finish.

What is Injection Molding?

Injection molding is a well-established, high-volume manufacturing process where molten plastic is injected into a mold under high pressure. It is highly suitable for mass production, delivering parts with consistent quality, strength, and excellent surface finishes. Injection molding requires significant upfront investment in tooling, but this investment becomes cost-effective for high-volume production, making it a go-to choice for industries such as automotive, electronics, and consumer goods.

Injection molding offers various specialized methods to meet different material needs, including:

- Thermoplastic Injection Molding: The most common type, using thermoplastics like ABS and polypropylene. It offers rapid cycle times and is ideal for large production runs.

- Thermoset Injection Molding: Uses thermosetting resins that cure permanently in the mold. This method is suitable for heat-resistant applications.

- Overmolding: Involves molding one material over another, such as creating a soft rubber grip over a hard plastic handle.

- Insert Molding: Inserts, such as metal components, are placed into the mold before plastic is injected around them, integrating multiple materials into one part.

- Micro Injection Molding: Used for very small, precise components, this method is often employed in the medical and electronics industries.

3D Printing vs. Injection Molding: Key Comparisons

1. Design Flexibility

3D printing excels in producing complex, customized designs with intricate geometries. Since parts are built layer by layer from digital files, there are virtually no design constraints. Features like internal channels, undercuts, or organic shapes can be easily produced. This makes 3D printing ideal for prototyping, small-batch production, and one-off designs where speed and flexibility are essential.

Injection molding, on the other hand, requires more consideration in the design process. Parts must be designed to fit within the mold constraints, which includes ensuring the right draft angles, wall thicknesses, and avoiding overly complex shapes that cannot be easily molded. While this limits some design freedom, injection molding can produce highly precise, repeatable parts in large quantities, making it ideal for mass production once the design is finalized.

2. Production Speed and Scalability

3D printing offers rapid prototyping, where the lead time to create a part can be just a few hours or days. However, since each part is produced individually, the overall production time for larger volumes can be slower. This is why 3D printing is better suited for short production runs or when rapid iteration is needed.

Injection molding, although requiring a longer lead time for tooling (often weeks to months), delivers fast cycle times once the mold is created. For large-scale manufacturing, injection molding is incredibly efficient and cost-effective. It excels in producing thousands to millions of identical parts quickly, making it the preferred choice for high-volume production.

3. Material Selection and Part Strength

3D printing supports a limited range of materials, including thermoplastics like PLA, ABS, nylon, and specialized resins. While these materials are suitable for many applications, they often lack the strength and durability of injection-molded parts. Additionally, 3D printed parts can have anisotropic properties, meaning they are stronger in one direction but weaker along others, due to the layer-by-layer printing process.

Injection molding, however, offers a much broader range of materials, including both commodity plastics like polypropylene (PP) and high-performance materials like PEEK, PEI, and medical-grade resins. Parts produced through injection molding have isotropic strength, meaning the material properties are consistent in all directions. This makes them more durable and suitable for high-stress applications, such as automotive or aerospace components.

4. Surface Finish and Accuracy

While 3D printing offers excellent flexibility in design, it often requires post-processing to achieve the desired surface finish. Depending on the printing method, 3D printed parts can have visible layer lines, rough textures, and slight dimensional inaccuracies, which may require sanding, polishing, or coating to achieve the desired result.

Injection molding typically produces parts with superior surface finishes directly out of the mold. With precision molds, manufacturers can achieve glossy, matte, or textured finishes with tight tolerances, making it ideal for applications where appearance and accuracy are paramount.

5. Cost Considerations

3D printing has a low upfront cost because it doesn’t require expensive molds or tooling. The main cost drivers in 3D printing are material costs, machine time, and post-processing. However, the cost per part can be relatively high, especially for larger quantities, and it becomes less cost-effective as production volumes increase.

Injection molding, on the other hand, requires a significant initial investment in mold design and fabrication, but the cost per part is much lower for large-scale production. After the mold is made, cycle times are fast, and the cost of producing each additional part decreases significantly, making it highly economical for mass production.

6. Environmental Impact

Both processes have environmental implications. 3D printing generates minimal material waste since it is an additive process, and only the necessary material is used to build the part. However, some 3D printing materials, like certain resins, can be difficult to recycle, and the energy consumption per part can be high.

Injection molding typically generates more waste in the form of sprues, runners, and scrap parts. However, these materials can often be recycled, making the process more sustainable at scale. Additionally, once the tooling is made, injection molding becomes highly efficient, producing large quantities of parts with minimal energy consumption per part.

3D Printing vs. Injection Molding: Which One is Right for You?

At Plantmetal, we offer a comprehensive one-stop service for both 3D printing and injection molding, ensuring that you get the highest quality parts for your project. Whether you need rapid prototyping, low-volume production, or large-scale manufacturing, our expertise as a manufacturer ensures that you choose the best process based on your specific needs.

Conclusion

Choosing between 3D printing and injection molding depends on several factors, including the complexity of your design, production volume, material requirements, and budget. For low-volume runs, prototypes, or complex geometries, 3D printing is the ideal choice. For mass production where cost efficiency, strength, and consistency are critical, injection molding is the superior option.

At Plantmetal, we are committed to providing high-quality manufacturing solutions, helping you navigate the decision-making process, and delivering the best parts for your needs. If you’re ready to bring your project to life, contact us today for more information, or upload your CAD model to get a free consultation and quote.