When it comes to manufacturing techniques, the ability to combine multiple materials into a single, durable component is essential for many industries. Two commonly used processes for achieving this are insert molding and overmolding. While they both combine different materials to create stronger, more functional products, there are important distinctions in terms of process, material compatibility, cost, and the final product’s application.

At Plantmetal, we specialize in providing a one-stop service for all types of manufacturing needs, including both insert and overmolding. With years of experience and a team of experts, we help guide our clients through the various stages of product design, material selection, and mass production, ensuring high-quality results every time.

In this blog, we will delve into the key differences, advantages, and applications of both insert molding and overmolding. Whether you’re looking to integrate metal components with plastic or enhance user comfort with a soft-touch layer, understanding these processes will allow you to make informed decisions for your next project.

What is Insert Molding?

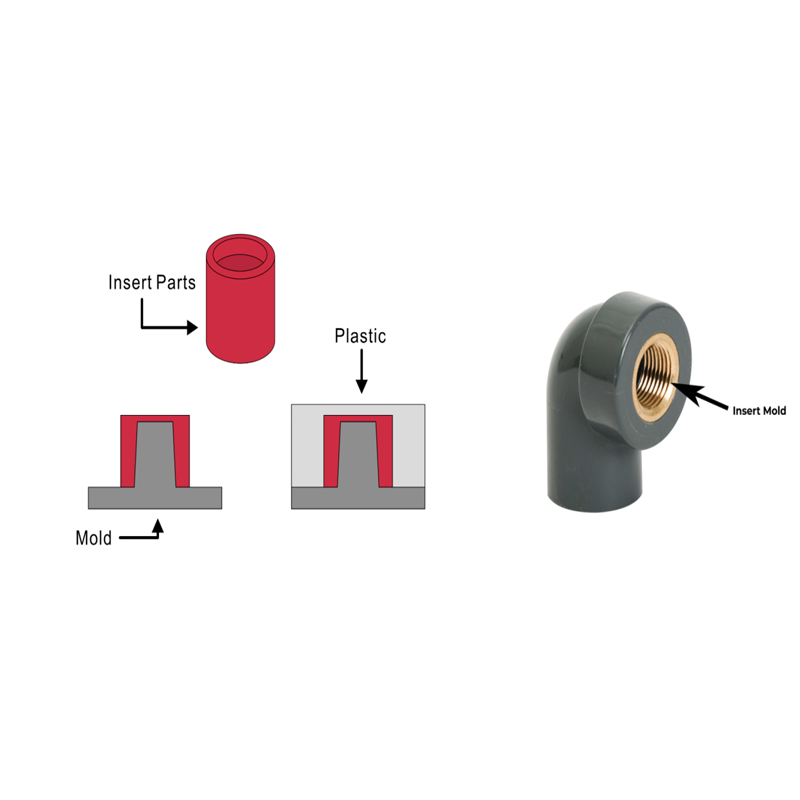

Insert molding is a manufacturing process in which a pre-formed component, typically made from metal, ceramic, or other non-plastic materials, is placed into a mold cavity before plastic is injected around it. This technique is widely used to add features such as electrical contacts, threaded inserts, or functional mechanical components into a single, integrated part.

Key Benefits of Insert Molding:

- Strength & Durability: By embedding materials like metal or ceramics into the plastic, insert molding improves the strength and functionality of the final product.

- Reduced Assembly Steps: With insert molding, you eliminate the need for fasteners, adhesives, and other secondary operations, making the overall production process more efficient.

- Cost-Effectiveness for Specific Applications: When embedding components such as connectors or metal inserts, insert molding offers a streamlined and cost-efficient solution for mass production.

Common Applications:

- Automotive Electronics: For connectors and other components that need enhanced mechanical strength.

- Medical Devices: Where adding functional elements like metal fasteners or electrical contacts is necessary.

- Consumer Goods: Such as power tools or electronics requiring the integration of strong and durable parts.

What is Overmolding?

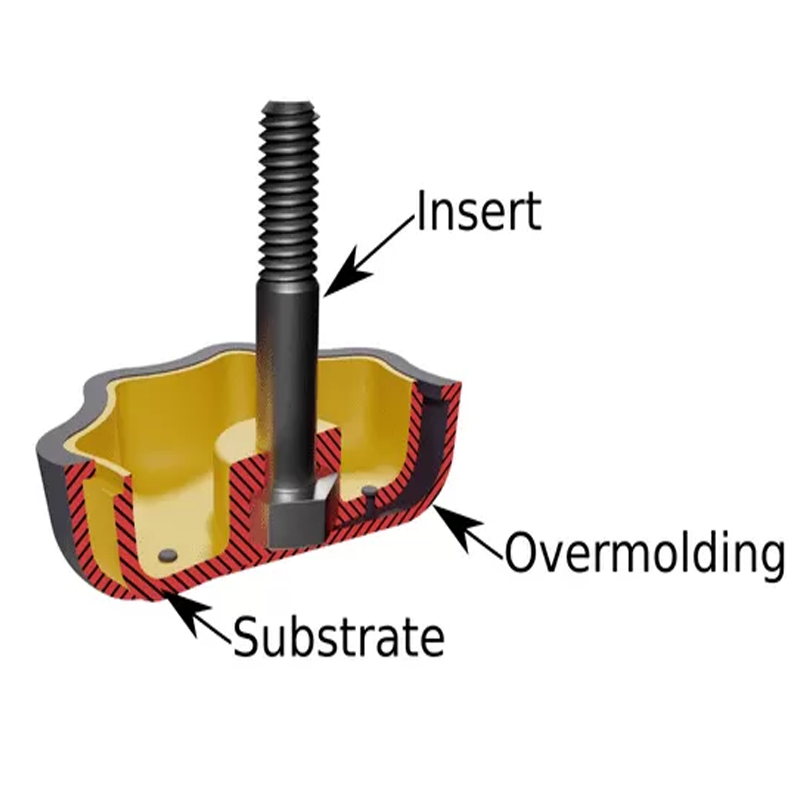

Overmolding involves the process of molding one material over another to create a single part with different layers of material properties. Typically, this involves injecting a soft material such as thermoplastic elastomers (TPE) or thermoplastic polyurethane (TPU) over a rigid plastic substrate. Overmolding is used to add aesthetic appeal, improve grip, or offer environmental sealing.

Key Benefits of Overmolding:

- Enhanced Comfort and Ergonomics: The softer material layer provides improved grip, making it ideal for products such as tool handles, baby products, and medical devices.

- Aesthetic Customization: Overmolding allows for the addition of colors, textures, and branding to the final product, enhancing its visual appeal.

- Superior Sealing and Protection: The process is often used to create waterproof or highly durable products, which is essential in industries such as automotive, medical, and electronics.

Common Applications:

- Tool Handles: For providing ergonomic comfort and reducing hand fatigue.

- Consumer Electronics: Including items like phone cases, where grip and aesthetics are paramount.

- Medical Devices: Such as handles or covers where both comfort and protection are needed.

Insert Molding vs. Overmolding: The Process Breakdown

While both insert molding and overmolding involve the integration of two or more materials, the processes themselves differ in several ways:

- Insert Molding Process:

- Step 1: A pre-formed insert (such as a metal or ceramic part) is manually or robotically placed into the mold cavity.

- Step 2: Molten plastic is injected into the mold, encapsulating the insert and bonding the materials together.

- Step 3: After cooling, the mold is opened, and the finished part is ejected.

- Overmolding Process:

- Step 1: A rigid base component (usually plastic) is first molded.

- Step 2: The base component is transferred into a secondary mold cavity where a second material, often softer, is injected over it.

- Step 3: The overmolded component is cooled, and the final part is ejected, offering a dual-material structure.

Key Differences in the Manufacturing Process:

- Insert Molding: Uses a pre-formed insert, typically made of metal, which is embedded into the plastic during the injection process.

- Overmolding: Involves two stages of molding—first creating the base component, then adding a second material layer over it.

Insert Molding vs. Overmolding: Cost Comparison

When considering the costs associated with both processes, the following factors should be taken into account:

- Insert Molding Costs:

- Typically lower tooling costs compared to overmolding, especially when integrating smaller metal parts.

- Requires careful alignment of the insert and proper molding process control.

- Overmolding Costs:

- Generally higher mold costs due to the need for multi-stage processes.

- Offers added value in functionality and aesthetics, which can justify the increased cost in certain applications.

- Ideal for mass production where the added features provide long-term benefits for end users.

Choosing the Right Process for Your Product

At Plantmetal, we offer OEM services and specialized manufacturing to ensure that your product’s design requirements are met with precision. Whether you choose insert molding or overmolding, our team of experts will guide you through the process to ensure your product not only meets functional needs but also aligns with your cost and quality expectations.

When to Choose Insert Molding:

- You need to integrate metal or ceramic components with plastic.

- You are looking for cost-effective manufacturing without sacrificing strength.

- You need a robust, functional part that requires minimal post-processing.

When to Choose Overmolding:

- You need to enhance user comfort, ergonomics, or aesthetics.

- You are looking for a water-tight or highly durable component.

- Multi-material integration is crucial for your product design.

Designing for Insert Molding and Overmolding: Key Considerations

Regardless of whether you are using insert molding or overmolding, proper part design is essential to the success of your project. At Plantmetal, we provide comprehensive custom services to help you design parts that are optimized for both processes:

- Insert Molding Design Considerations:

- Use undercuts, grooves, or other features to improve the mechanical bond between the insert and the plastic.

- Ensure the insert is properly aligned to avoid misalignment issues during the injection process.

- Overmolding Design Considerations:

- Ensure proper draft angles for easy removal of the overmolded part.

- Choose materials that have compatible melt temperatures to prevent distortion during the overmolding process.

Conclusion:

When it comes to choosing between insert molding and overmolding, the best solution depends on your product’s unique needs. At Plantmetal, we are dedicated to providing high-quality, cost-effective solutions that fit your manufacturing requirements. With our one-stop service, expert guidance, and years of experience, we help you navigate the complexities of product development, ensuring successful results every time.

Ready to get started? Contact us today for expert advice and custom molding solutions tailored to your needs. Our experienced team is here to ensure that your project progresses smoothly, efficiently, and successfully.