Description :

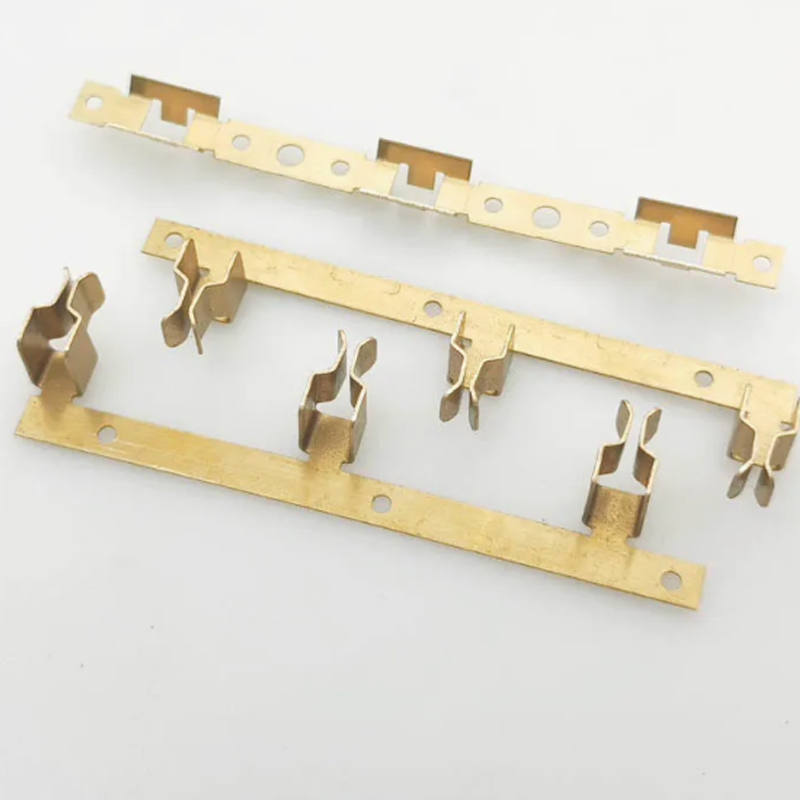

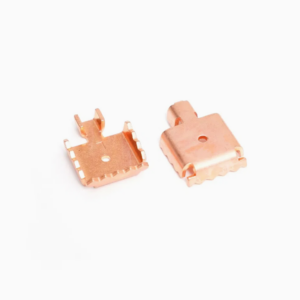

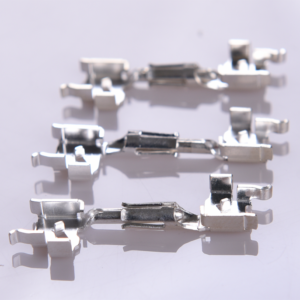

Nos connecteurs de bornes de batterie en laiton et en cuivre, estampés sur mesure, sont conçus pour offrir une conductivité, une durabilité et une stabilité mécanique supérieures pour les systèmes électriques automobiles et motocyclistes. Fabriquées à partir de matériaux en laiton et en cuivre de haute qualité, ces bornes sont conçues pour résister à de fortes charges de courant tout en assurant une transmission de puissance fiable. Des techniques d'estampage progressif avancées et des outils de précision garantissent des tolérances strictes, une qualité constante et un excellent ajustement pour différentes configurations de batteries.

Entièrement conformes aux normes de qualité ISO9001 et IATF16949, ces connecteurs sont sur mesure pour répondre aux exigences strictes des industries automobile et motocycliste. Qu'ils soient utilisés dans des moteurs de démarrage, des alternateurs ou des systèmes de distribution d'énergie générale, nos bornes de batterie offrent des performances durables dans des environnements exigeants.

Informations de base :

| Attribut | Détails |

|---|---|

| Lieu d'origine | Xiamen, Chine |

| Nom de la marque | OEM |

| Processus | Emboutissage Métallique Progressif, Formage Secondaire, Usinage de Précision |

| Matériau | Laiton C2680, Cuivre C1100/C1220, Bronze au phosphore, Cuivre béryllium |

| Tolérance | ±0,01 mm |

| OEM | Chaleureusement bienvenu |

| Contrôle Qualité (CQ) | 100 % d'inspection (premier article, en cours de fabrication, final) |

| Standard | ISO9001, IATF16949 |

| Taille | Personnalisé |

| Exemple | Disponible sur demande |

Avantages de nos bornes de batterie :

- Excellente conductivité électrique pour un flux de courant fiable.

- Haute résistance mécanique pour résister au couple et aux vibrations dans les applications automobiles.

- Options de finition résistantes à la corrosion pour une durée de vie prolongée.

- Capacité de conception sur mesure pour s'adapter à divers modèles de batteries automobiles et de motos.

- Léger mais durable pour une efficacité et des performances accrues.

Options de traitement de surface alternatives :

- Placage d'étain : Assure une résistance à la corrosion et une excellente soudabilité, couramment utilisé dans les connecteurs automobiles.

- Nickelage : Améliore la résistance à l'usure et fournit une surface stable et conductrice pour des environnements exigeants.

- Argenture : Offre une excellente conductivité et durabilité, idéale pour les systèmes électriques haute performance.

- Plaquage en or : Offre une résistance à la corrosion et une conductivité inégalées, adaptées aux applications de qualité supérieure.

- Passivation et revêtements anti-oxydation : prolongez la durée de vie des bornes en laiton et en cuivre dans des environnements difficiles.

Pourquoi s'associer avec nous ?

- Tarification compétitive : Solutions directes d'usine pour des économies sans compromettre la qualité.

- Contrôle de qualité strict : inspections à 100 % soutenues par les certifications ISO9001 et IATF16949.

- Support client complet : De la consultation en design à la logistique et au service après-vente.

- Livraison fiable : Une gestion de projet efficace garantit un approvisionnement régulier et ponctuel pour les clients du monde entier.

Notre Usine :

Notre installation de production est équipée de 30 presses à poinçonner de précision allant de 25 à 300 tonnes, ainsi que de centres d'usinage CNC avancés, de machines de découpe par fil EDM de précision et de lignes de estampage à grande vitesse pour la production en gros volumes. Nous utilisons également des systèmes de nettoyage ultrasonique, des équipements de soudage et de polissage, ainsi que des lignes d'assemblage automatisées pour garantir une qualité de produit constante.

Pour la finition, nous proposons une large gamme de services de galvanoplastie, notamment le placage en étain, en nickel, en argent et en or, garantissant une excellente conductivité, une résistance à l'usure et la conformité aux normes de l'industrie automobile. Avec les certifications ISO9001 et IATF16949, notre production automatisée et nos protocoles d'inspection rigoureux garantissent que chaque connecteur de terminal de batterie répond aux normes les plus élevées en matière de performance, de fiabilité et de durabilité.