When it comes to robotics and automation, the material selection process is one of the most critical decisions you’ll make. Choosing the wrong material can result in costly failures, system downtime, and potentially disastrous redesigns. In contrast, the right material can lead to high performance, durability, and reliability from the start. At Plantmetal, we understand the complexities involved in selecting the ideal materials for robotics, and we specialize in delivering the perfect balance between performance and cost. In this blog, we will discuss the factors to consider when choosing materials, the most common materials used in robotics, and how our expertise in manufacturing and custom solutions can ensure your robotic system runs smoothly for years to come.

Common Materials Used in Robotics and Automation

The materials you choose for your robotic components can vary depending on the specific requirements of your project. The most commonly used materials in robotics include metals, plastics, and composites. Each material type offers unique advantages, and understanding these will help you make an informed decision for your application.

Metals: Strength and Durability

Metals are the backbone of many robotic systems due to their superior strength and durability. Common metals used in robotics include:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine, aluminum is widely used in robotic frames, arms, and structural components. Its high strength-to-weight ratio makes it ideal for applications where speed and efficiency are crucial.

- Stainless Steel: Known for its excellent corrosion resistance, stainless steel is often used in industrial robots, particularly those in food-grade or medical environments. It offers superior strength and durability, especially in heavy-duty applications.

- Titanium: Titanium is used in applications requiring lightweight but strong components. It’s known for its high strength-to-weight ratio and corrosion resistance, making it ideal for high-performance robotic arms or aerospace applications.

Plastics: Lightweight and Insulating

Plastics are increasingly being used in robotics due to their lightweight properties, electrical insulation capabilities, and resistance to corrosion. Some key plastics include:

- Delrin (Acetal): Delrin is ideal for gears, bearings, and other moving parts due to its low friction, high wear resistance, and ease of machining. It is commonly used in precision robotics to reduce noise and wear.

- PEEK: This high-performance plastic is ideal for applications that require resistance to high temperatures, chemicals, and wear. PEEK is often used in industrial robots that operate in extreme conditions.

Composites: Strength-to-Weight Ratio

Composites, especially carbon fiber, offer an excellent strength-to-weight ratio, making them perfect for high-performance applications, such as high-speed robot arms, drones, or vehicles. Although composites can be expensive and difficult to machine, their benefits in performance and durability make them a premium material choice for specialized applications.

Key Considerations for Material Selection

Choosing the best material for your robotics application depends on several factors. Here are the key considerations to take into account when selecting materials for your robotic components:

1. Mechanical Properties: Strength and Stiffness

The strength-to-weight ratio is a key factor when selecting materials. Robotic components need to be strong enough to handle heavy lifting, precise movements, and repetitive tasks without flexing or bending. Aluminum, steel, and titanium are commonly chosen for their strength and stiffness. However, materials like carbon fiber offer even greater strength-to-weight ratios for high-performance applications where weight is a critical factor.

2. Weight and Speed

Lighter materials allow robots to move faster, consume less energy, and require smaller motors. This is why aluminum and carbon fiber are often the preferred choices for high-speed robots, as they reduce energy consumption and improve efficiency. When designing your robotic system, the weight of the material directly influences the speed and energy efficiency of the entire system.

3. Operating Environment

Robots often operate in harsh environments, whether they are exposed to high temperatures, chemicals, humidity, or abrasive surfaces. Materials like stainless steel and PEEK are known for their resistance to corrosion, heat, and chemicals, making them ideal for food processing, medical, and industrial applications.

4. Durability and Fatigue Resistance

Robots are designed to perform millions of cycles. Therefore, materials must withstand repeated stress and fatigue. For instance, stainless steel and titanium have excellent fatigue resistance and can handle heavy-duty tasks without failing over time. For long-term durability, ensuring that your material has good fatigue resistance is essential for maintaining performance.

5. Cost and Manufacturability

While high-performance materials like titanium and carbon fiber offer impressive strength and durability, they can also be costly and challenging to machine. Aluminum and steel, on the other hand, are easier to machine and more affordable, making them ideal for large-scale production. It’s important to balance the performance of the material with the manufacturing costs to achieve the best value for your project.

Why Plantmetal Is the Right Choice for Your Robotics Materials and Manufacturing Needs

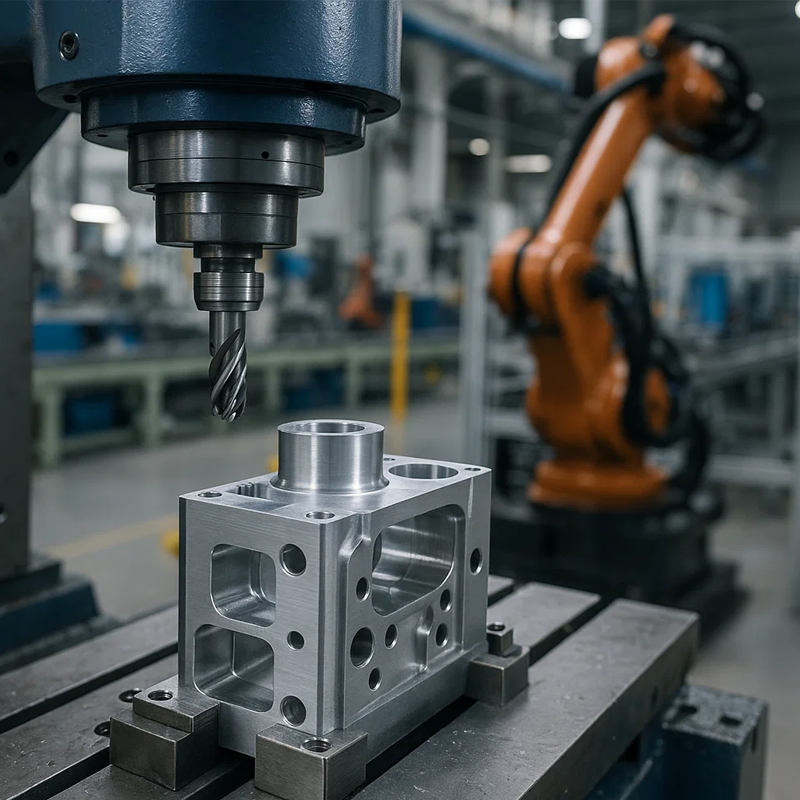

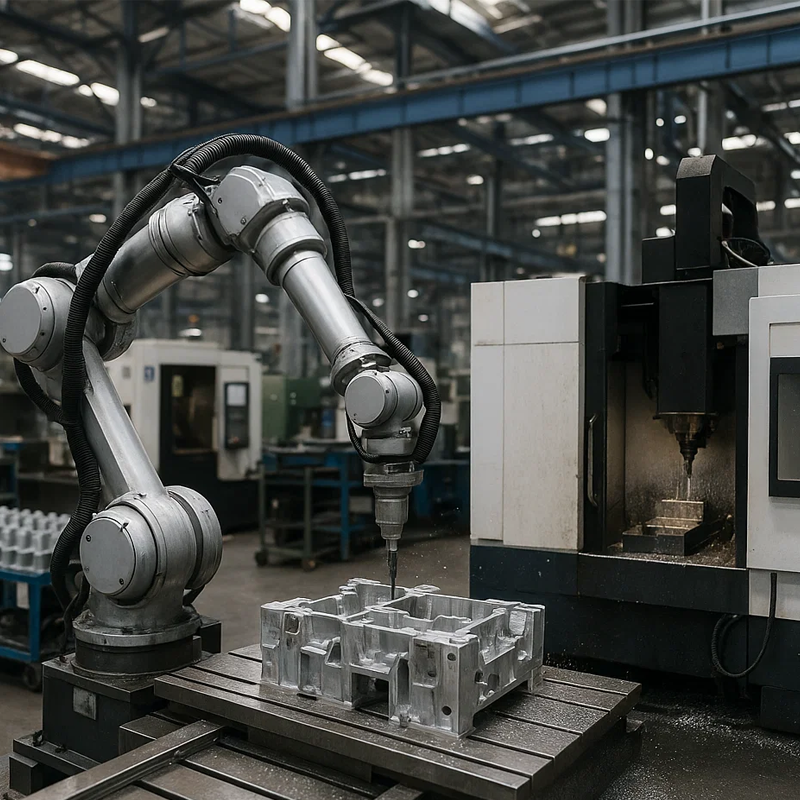

At Plantmetal, we offer OEM services and custom manufacturing solutions to help you select and produce the right materials for your robotics applications. Our expertise in metal stamping, CNC machining, and surface treatments allows us to deliver high-precision, reliable, and durable components that meet your exact specifications.

Quality Assurance and Expertise

Our factory is equipped with state-of-the-art machinery and inspection equipment, including 3D coordinate measuring machines (CMM) and tensile testers, to ensure that every component meets the highest quality standards. With ISO 9001 certification and a commitment to consistent quality management, we guarantee precision manufacturing and long-term reliability.

Customization and Flexibility

We understand that every robotics project has unique requirements, which is why we offer tailored solutions to suit your needs. Whether you need high-strength components for industrial applications or lightweight parts for high-speed robots, our team is here to support your project from prototyping to full-scale production.

Conclusion:

Selecting the right material is one of the most critical decisions in robotics and automation. By carefully considering mechanical properties, weight, environmental factors, and cost, you can make the best choice for your project. At Plantmetal, we have the expertise, equipment, and quality control processes to help you create reliable and high-performance robotic systems.

Ready to start your project? Contact us today to discuss how we can help you select the perfect materials and deliver customized, high-quality components for your robotics and automation needs. Let’s create something extraordinary together!