Thanks — if you’re evaluating surface finishes for a project, you’ve come to the right place. Below is a manufacturer-focused, professional deep dive on chrome plating written from the perspective of a precision parts factory (Plantmetal). I’ll explain how chrome plating works, the main process variants, equipment and control parameters, common defects and fixes, alternative coatings, and practical guidance for choosing the right method for your OEM or contract manufacturing run. If you’d like, we can also review your drawings and recommend a finish (we offer OEM service and high-precision manufacturing support and work with trusted suppliers).

What is chrome plating and why manufacturers use it

Chrome plating (chromium electroplating) deposits a thin layer of chromium metal onto a substrate to deliver a bright, hard, corrosion-resistant surface. The trade-off is key: even microns of chromium dramatically improve wear resistance, surface hardness, cleanability, and visual appeal. For decorative trim you get a mirror-like finish; for industrial parts you can apply thick hard chrome to restore worn geometry or extend service life.

From a factory standpoint, chrome is attractive because it:

- Combines high-precision dimensional restoration (hard chrome) with excellent surface properties.

- Serves both decorative and engineering applications (automotive trim versus hydraulic rods).

- Is compatible with typical metalworking workflows (machining → polishing → plating → finishing).

How chrome plating works — the basics

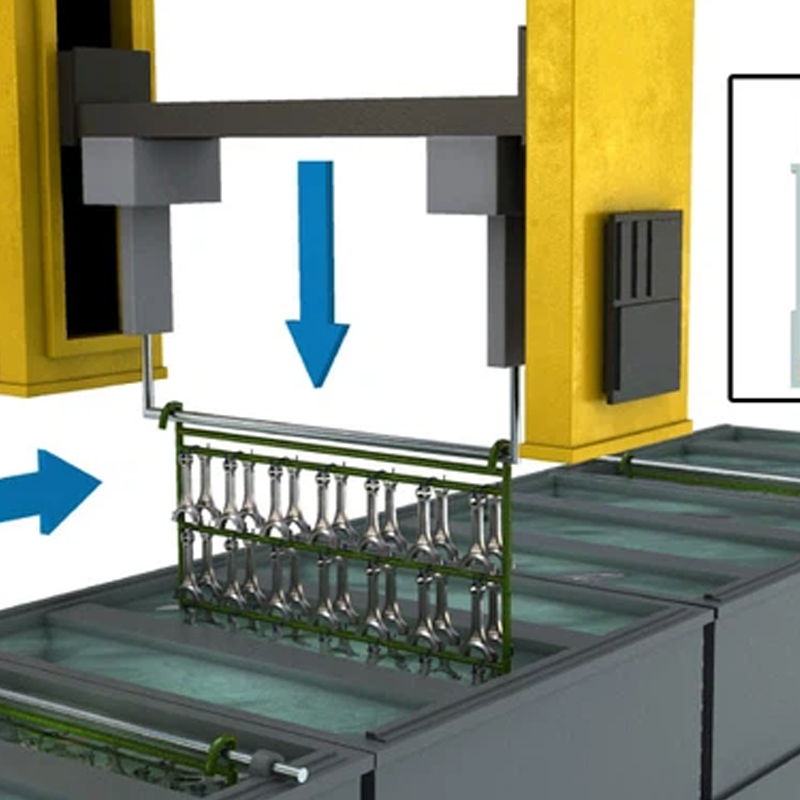

Electroplating uses DC electricity to reduce metal ions in a bath and deposit them onto a conductive workpiece (the cathode). For chromium plating:

- The part is pretreated (clean, degrease, etch/activate, and often a nickel underlayer for decorative chrome).

- The part is immersed in a chromium-containing electrolyte (hexavalent Cr⁶⁺ baths historically used chromic acid; trivalent Cr³⁺ baths use chromium salts and complexing agents).

- A rectifier applies a controlled current; chromium ions are reduced and form a tightly adherent metallic layer.

Key process variables that determine quality are current density, bath composition, temperature, agitation, and plating time — all of which must be tightly controlled to meet OEM tolerances.

A short manufacturing history note

Commercial chromium electroplating matured in the 1920s. For decades hexavalent chromic acid baths dominated because they produced reliable bright finishes and thick hard chrome. Since the 1970s environmental and safety regulations have driven R&D into trivalent chemistries and alternative technologies. Today many shops are migrating to Cr³⁺ for decorative chrome while still using Cr⁶⁺ legacy processes in regulated, well-controlled hard-chrome applications — always balancing regulatory compliance, performance, and cost.

Main types of chrome plating and when to use them

- Decorative (Bright) Chrome — extremely thin (microns). Used for appearance and light corrosion protection on trim, faucets, and consumer hardware. Usually plated over nickel for brightness and adhesion.

- Hard Chrome (Industrial/Engineering Chrome) — thick deposits (hundreds of microns to mm) for wear resistance, low friction and dimensional restoration (hydraulic rods, molds, shafts). Often produced from high-current hexavalent baths.

- Thin Dense Chrome (TDC) — thin, crack-minimized chrome offering high hardness with better barrier properties than conventional cracked chrome. Ideal for tooling and aerospace precision parts.

- Flash Chrome — very thin coating applied quickly for minor corrosion resistance or as a finish on metalized plastics.

- Satin / Black Chrome — decorative variants that alter the texture or crystalline structure for a matte or dark metallic appearance.

- Composite / Particle-Reinforced Chrome — chrome co-deposited with ceramic or carbide particles for extreme wear applications.

Process control — what we watch in the factory

To achieve repeatable results we monitor and log:

- Current density: controls deposition rate and surface morphology. Decorative: low; hard chrome: high.

- Bath temperature: affects deposit quality and throwing power.

- Bath composition and filtration: contaminants create pits and roughness; filtration and replenishment are critical.

- Agitation and anode placement: ensure uniform ion distribution and consistent thickness on complex geometries.

- Time / thickness: for decorative chrome seconds to minutes; for hard chrome, hours.

Modern plating lines integrate PLCs, rectifiers with ripple control, and environmental capture systems — required both for quality and regulatory compliance.

Typical substrates and pretreatment

Chrome can be applied to steel, stainless steel (with a nickel strike), copper and brass, zinc die-cast (with copper strike), aluminum (zincate → nickel), and even plastics after chemical etch + electroless copper/nickel deposition. Proper pretreatment (degreasing, activation, strike layers) is the single most important step to avoid adhesion failures later.

Common defects and practical fixes

- Peel / Blistering: poor cleaning or activations. Fix: improved pretreatment, correct strike layers and bake processes.

- Pitting / porosity: contamination, poor agitation or trapped gas; fix with better filtration and adjusted bath chemistry/agitation.

- Uneven coverage (poor throwing power): typical for Cr⁶⁺; use auxiliary anodes, longer plating, or switch to trivalent chemistry where appropriate.

- Burning / rough deposits: excessive current density; reduce current, adjust temperature.

- Cracking / internal stress in thick layers: manage thickness per pass, consider pulse plating or thin dense chrome processes.

Manufacturing teams should run process qualification trials and maintain control charts for these variables.

Environmental, safety and regulatory considerations

Hexavalent chromium (Cr⁶⁺) is toxic and strictly regulated. Facilities must have fume capture, mist suppression, wastewater treatment, and extensive PPE and monitoring programs. Trivalent chrome reduces hazard and disposal burden but requires tighter bath control and often higher chemistry costs. As OEMs and suppliers, we help customers evaluate total lifecycle cost (process, compliance, throughput) — not just chemical cost per liter.

Alternatives and when to choose them

If chrome’s environmental or geometric constraints are problematic, alternatives include:

- Electroless nickel (uniform coverage and good wear resistance)

- PVD coatings (vacuum-deposited, decorative metallic finishes)

- Powder coating (durable color finishes without chrome)

- Anodizing (for aluminum parts)

- Thermal spray / HVOF (thicker wear-resistant layers)

We recommend alternatives when heavy environmental controls are impractical, or when complex internal geometries need uniform coatings.

Maintenance, stripping and re-chroming

Hard chrome can be stripped mechanically, chemically (acid or caustic processes) or electrolytically and the part re-plated — a common, cost-effective option for restoring worn components. Proper cleaning, dimensional restoration (welding or build-up if required), and re-machining are part of a standard reflating workflow.

Practical selection guidance for OEMs and manufacturers

- For decorative trim choose trivalent chrome where possible for lower regulatory burden and acceptable performance — ensure a bright nickel underplate and polish prep.

- For wear-critical parts, hard chroming remains a top choice for high hardness and low friction; plan for longer cycle times and waste controls.

- For precision tooling, consider Thin Dense Chrome or composite chrome for extended life and precise surface properties.

- Always specify surface finish (Ra), minimum thickness, adhesion tests, and acceptance criteria in your drawing’s finish note. We support DFM (design for manufacturability) reviews to optimize geometry for plating (avoid deep blind holes, provide draft/fixturing areas).

Cost considerations

Chrome plating costs vary by type, part size, thickness and prep. Decorative flash chrome is inexpensive per part; thick hard chrome can be materially and time intensive. However, plating to restore worn parts is often more cost-effective than fabricating new components.

Industry standards and quality control

Relevant standards include ASTM and AMS specifications for chromium coatings and aerospace/hydraulic requirements. In a factory setting we implement batch records, thickness checks (x-ray fluorescence or micrometers after machining), adhesion testing, and visual inspection protocols to ensure compliance.

Conclusion

Chrome plating is a powerful finishing option that bridges aesthetic elegance and engineering performance. At Plantmetal we combine high-precision manufacturing, DFM support, and a network of vetted plating suppliers to deliver OEM service and finished parts that meet demanding production and compliance requirements. If you need help selecting a plating route — whether decorative trivalent chrome for consumer hardware or hard chromium for hydraulic rods — we can run a feasibility study, trial parts, and recommend the most cost-effective, compliant process for your production volumes.

Contact Plantmetal to discuss your part, required finish, and production timeline — we’ll provide a tailored recommendation that balances manufacturing cost, performance, and regulatory compliance and source trusted suppliers when needed.