Panoramica:

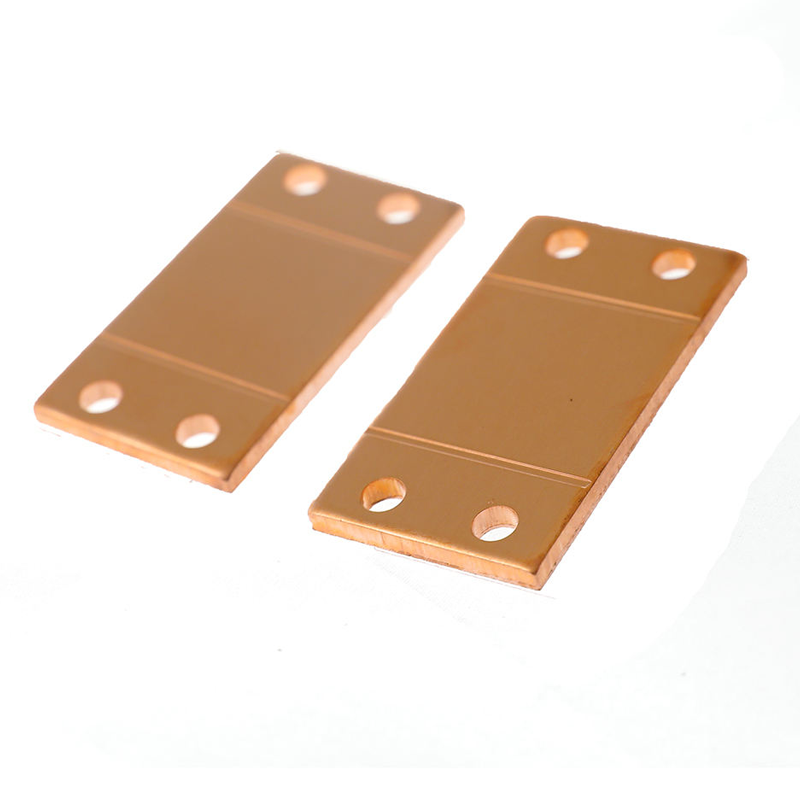

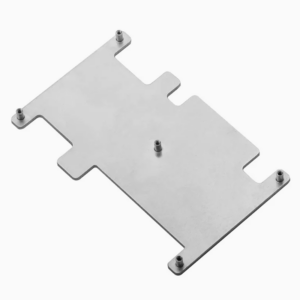

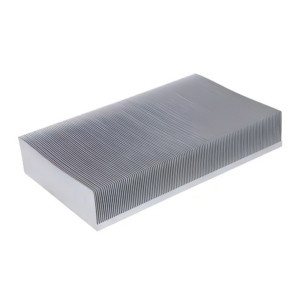

Il dissipatore di calore in lamiera di rame personalizzato, realizzato con taglio laser, è progettato per dissipare efficacemente il calore e mantenere un controllo ottimale della temperatura nei componenti elettronici. Realizzati utilizzando rame di alta qualità, noto per la sua eccellente conduttività termica, questi dissipatori di calore sono fabbricati attraverso tecniche di taglio laser di precisione e formatura della lamiera. Questo processo garantisce dimensioni precise, durata migliorata e superiori proprietà di dissipazione del calore. Ideali per applicazioni nell'elettronica, nelle alimentazioni, nell'automotive e nei settori industriali, i nostri dissipatori di calore personalizzati offrono soluzioni di gestione termica affidabili, adattate a requisiti specifici.

La nostra fabbrica è specializzata nella lavorazione dei metalli su misura e offre soluzioni complete, fornendo design, dimensioni, materiali e opzioni di finitura personalizzati. Che tu abbia bisogno di produzione ad alto volume o di progetti a bassa miscela e alta complessità, garantiamo qualità superiore e processi di produzione efficienti. Contattaci oggi per discutere delle tue specifiche esigenze di dissipatori di calore e richiedere un preventivo per la tua soluzione personalizzata.

Informazioni di Base:

| Attributo | Dettagli |

|---|---|

| Materiale | Rame (C1100, C2600 o altri) |

| Processo di Fabbricazione | Taglio Laser,Punzonatura CNC,Piegatura,Formatura |

| Taglia | Personalizzato |

| Lunghezza | Personalizzato |

| Spessore | Personalizzato |

| Certificazione | ISO, RoHS, SGS |

| Trattamento Superficiale | Here are the translations in Italian: - Electroplating: Elettrodeposizione - Nickel Plating: Nichelatura - Tin Plating: Stagnatura - Anodizing: Anodizzazione |

| MOQ | In base alle tue esigenze |

| Imballaggio | Personalizzato |

| Campione | Disponibile |

| Marchio | OEM |

| Origine | Xiamen, Cina |

Benefici dei nostri prodotti:

- Conduttività Termica Superiore

Il rame è ampiamente conosciuto per le sue eccezionali capacità di dissipazione del calore, rendendolo ideale per l'uso in dissipatori di calore che gestiscono in modo efficiente le prestazioni termiche in applicazioni ad alta richiesta. - Produzione di Precisione

I nostri processi di taglio laser e punzonatura CNC garantiscono dimensioni precise e tolleranze strette, offrendo dissipatori di calore ad alte prestazioni con una qualità costante. - Fabbricazione su misura

Offriamo piena personalizzazione, dalla selezione dei materiali alle opzioni di dimensione e finitura, garantendo che i vostri dissipatori di calore soddisfino i vostri specifici requisiti di design e prestazioni. - Durabilità e Resistenza alla Corrosione

Con una varietà di opzioni di trattamento superficiale come la galvanizzazione in nichel o l'anodizzazione, i nostri dissipatori di calore offrono una maggiore durata, resistenza alla corrosione e prestazioni di lunga durata, anche in ambienti difficili.

Assicurazione della Qualità:

La nostra assicurazione qualità per la fabbricazione personalizzata di dissipatori in lamiera di rame include un rigoroso rispetto degli standard di settore e protocolli di test completi. Utilizziamo strumenti di misurazione ad alta precisione come macchine di misura a coordinate (CMM), interferometri laser e attrezzature termografiche per garantire la precisione dimensionale e le prestazioni termiche ottimali. Ogni lotto viene sottoposto a un'ispezione rigorosa per l'integrità del materiale, la finitura superficiale e l'efficienza termica. La nostra struttura è certificata ISO 9001, garantendo una qualità costante e la conformità agli standard internazionali. Inoltre, tutto il rame utilizzato nel processo di produzione è testato per purezza e resistenza alla corrosione per garantire elevate prestazioni e longevità.

La Nostra Fabbrica:

La nostra moderna struttura di produzione è dotata di macchinari avanzati, tra cui macchine per il taglio laser, presse per punzonatura CNC e sistemi di piegatura automatizzati. Queste tecnologie garantiscono alta precisione ed efficienza nella produzione di dissipatori di calore in lamiera di rame. Con un focus sulla qualità, utilizziamo anche tecniche di rivestimento avanzate come il nichelatura, la stagnatura e l'anodizzazione per migliorare la durata e le prestazioni dei nostri prodotti. I nostri ingegneri esperti e il team di produzione seguono procedure di controllo qualità rigorose in ogni fase del processo, assicurando che ogni dissipatore di calore soddisfi i vostri requisiti specifici per la gestione termica e la durabilità. Con un impegno per l'eccellenza, garantiamo tempi di consegna rapidi e affidabili, supportati dalla nostra certificazione ISO 9001.