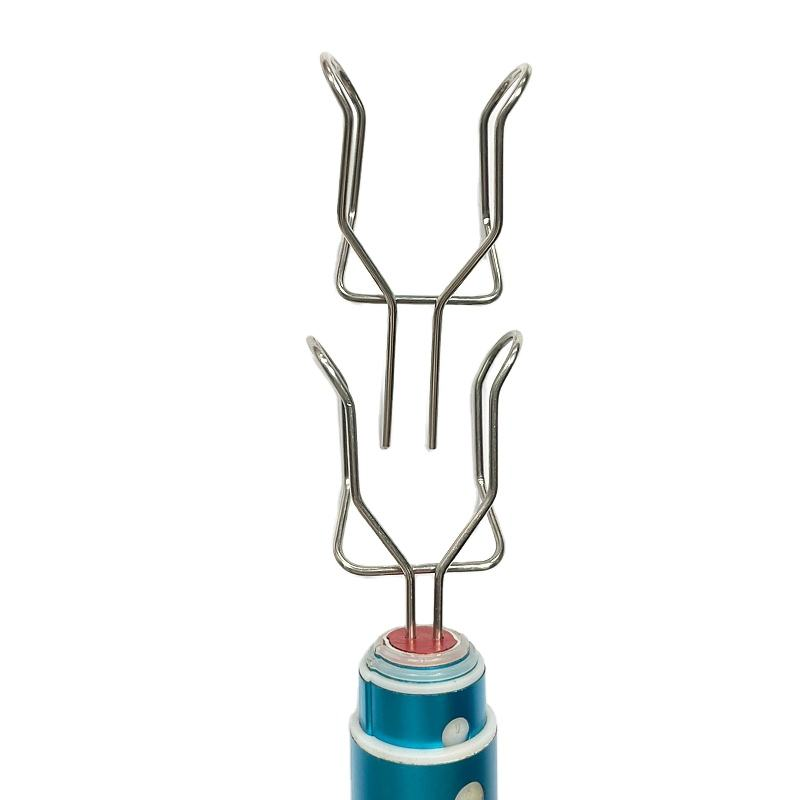

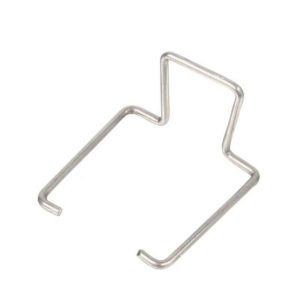

Panoramica

Le molle a forma di filo in acciaio inossidabile elettroplaccato personalizzate sono componenti ingegnerizzati con precisione, realizzati attraverso processi avanzati di formatura del filo e elettroplaccatura. Realizzate in acciaio inossidabile di alta qualità, queste molle offrono una resistenza meccanica superiore, resistenza alla corrosione ed eccellente elasticità. La finitura elettroplaccata personalizzata migliora ulteriormente la durata, fornisce specifiche proprietà superficiali e garantisce un'affidabilità a lungo termine in applicazioni impegnative. In quanto produttore e fornitore specializzato, offriamo soluzioni di molle su misura dalla progettazione alla produzione, soddisfacendo specifiche esatte per forza, deflessione, dimensioni e rivestimento per soddisfare le diverse esigenze industriali.

Caratteristiche

| Attributo | Dettagli |

|---|---|

| Luogo di Origine | Xiamen, Cina |

| Nome del Marchio | OEM |

| Materiale di Base | Acciaio Inossidabile (302, 304, 316), Filo Musicale, Acciaio al Carbonio, ecc. |

| Servizio | OEM, Design e Produzione Personalizzati |

| Tipo di Rivestimento | Zinco, Nichel, Cromo, Stagno, Oro o Galvanizzazione Personalizzata |

| Applicazione | Automotive,Elettronica,Elettrodomestici, Attrezzature Industriali, Dispositivi Medici |

| Certificazioni | ISO9001, IATF 16949, RoHS |

| Servizio post-vendita | Supporto Ingegneristico e Assicurazione Qualità |

| MOQ | Si accettano anche piccoli ordini. |

| Dimensioni e Specifiche | Personalizzato (Diametro del filo, OD, ID, Numero di spire, Lunghezza libera) |

Processo di Produzione

-

Selezione e Preparazione del Filo: Si seleziona un filo in acciaio inossidabile di alta qualità o un altro filo in lega in base alla resistenza alla trazione richiesta, alla resistenza alla corrosione e alla vita a fatica. Il filo viene trafilato con precisione al diametro specificato.

-

Formatura di Fili di Precisione: Il filo viene alimentato in macchine per la formatura di fili CNC controllate da computer o avvolgitori di molle. Queste macchine piegano e modellano il filo con alta precisione in complesse geometrie di molle 2D o 3D, garantendo un passo, un angolo e una configurazione delle gambe costanti.

-

Trattamento Termico (Rilascio dello Stress): Le molle formate subiscono un processo di trattamento termico controllato per alleviare le tensioni interne indotte durante la piegatura, stabilizzando la struttura e ottimizzando le proprietà meccaniche della molla e la resistenza alla deformazione.

-

Finitura superficiale e elettrodeposizione: Le molle vengono pulite e preparate per l'elettrodeposizione. Sottoposte a un processo di elettrodeposizione personalizzato (ad esempio, zinco per la protezione dalla corrosione, nichel per la resistenza all'usura) in linee di placcatura automatizzate, ricevono un rivestimento metallico uniforme e aderente che soddisfa gli standard di spessore e prestazioni specificati.

-

Ispezione Qualità e Imballaggio: Ogni lotto subisce un'ispezione rigorosa utilizzando comparatori ottici, tester di carico e tester di nebbia salina per verificare le dimensioni, le caratteristiche di forza, la qualità del rivestimento e la resistenza alla corrosione. Le molle approvate vengono poi imballate con cura per prevenire danni durante il trasporto.

Perché Scegliere Noi?

-

Supporto personalizzato per ingegneria e design: Forniamo un'analisi completa per la progettazione orientata alla fabbricazione (DFM) e servizi di prototipazione per trasformare il tuo concetto in una soluzione a molla ad alte prestazioni e producibile.

-

Selezione Esperta di Materiali e Processi: Il nostro team fornisce consulenza sulla combinazione ottimale di materiale di base e rivestimento per raggiungere il perfetto equilibrio tra resistenza, resistenza alla corrosione, conducibilità e costo per la tua applicazione.

-

Produzione Flessibile e Prototipazione Rapida: Accogliamo ordini da piccoli lotti di prototipi a produzioni in alta quantità, garantendo una risposta agile ai tempi e alle esigenze di sviluppo del tuo progetto.

-

Controllo Qualità e Conformità Rigorosi: Il nostro sistema di gestione della qualità integrato, supportato da certificazioni di settore e attrezzature di test avanzate, garantisce che ogni molla soddisfi precise specifiche dimensionali, meccaniche e di durabilità.

Spettacolo della Fabbrica

La nostra struttura di produzione specializzata è dotata di un insieme di macchinari avanzati dedicati alla produzione di molle di precisione. Le nostre capacità principali includono macchine di formatura fili CNC a più assi, avvolgitori di molle a controllo computerizzato e forni automatizzati per il trattamento termico. Per il miglioramento della superficie, gestiamo linee di elettroplaccatura completamente integrate, in grado di applicare vari rivestimenti metallici con un controllo preciso dello spessore. La qualità è garantita attraverso laboratori interni dotati di tester di torsione/compressione, camere di nebbia salina e sistemi di misurazione 3D. Questo ambiente di produzione verticalmente integrato e controllato per processi, regolato dagli standard ISO 9001 e IATF 16949, ci consente di fornire molle formate da filo personalizzate di eccezionale coerenza, prestazioni e affidabilità per le applicazioni globali più esigenti.