Want a clear, practical guide to whether wet etching or dry etching is the right choice for your next microfabrication or surface-preparation project? Great — you’re in the right place. At Plantmetal, we work daily with engineers and product teams to select, optimize, and qualify etch processes that balance cost, precision, and manufacturability. Below is a professional, application-driven breakdown of both technologies, how they work, where each excels, and how to choose the best approach for your parts.

What is etching and why it matters

Etching is the controlled removal of material from a substrate to transfer a pattern or to expose/clean a surface. In advanced manufacturing and microfabrication, etch steps set feature dimensions, define sidewall profiles, and directly influence device yield, reliability, and downstream processing (bonding, plating, coating). The choice between wet and dry etch affects dimensional control, surface finish, throughput, cost, and environmental/safety requirements — so it’s a core engineering decision, not just a shop-floor detail.

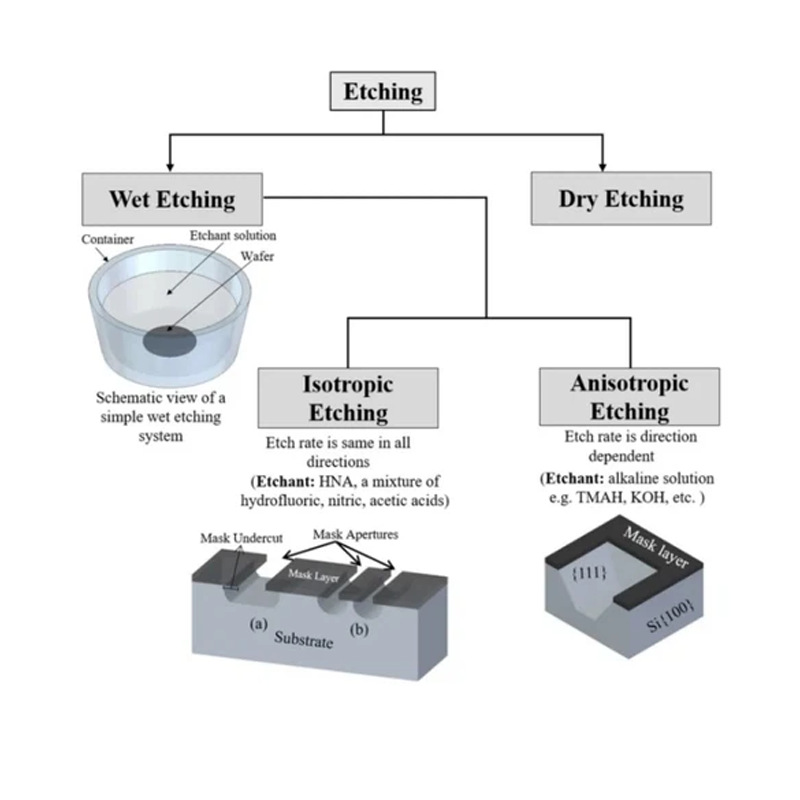

How wet etching works

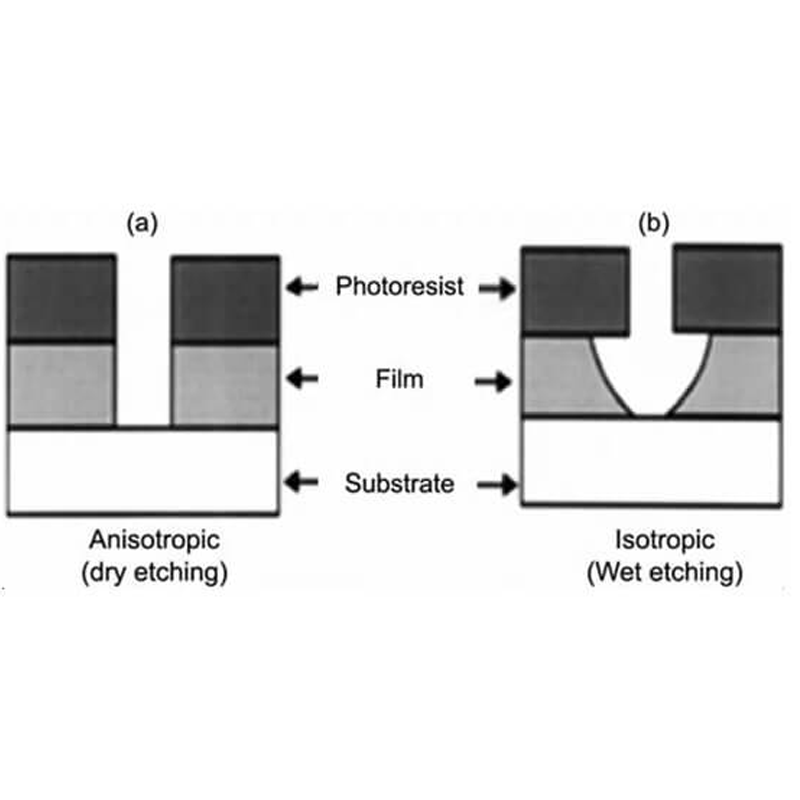

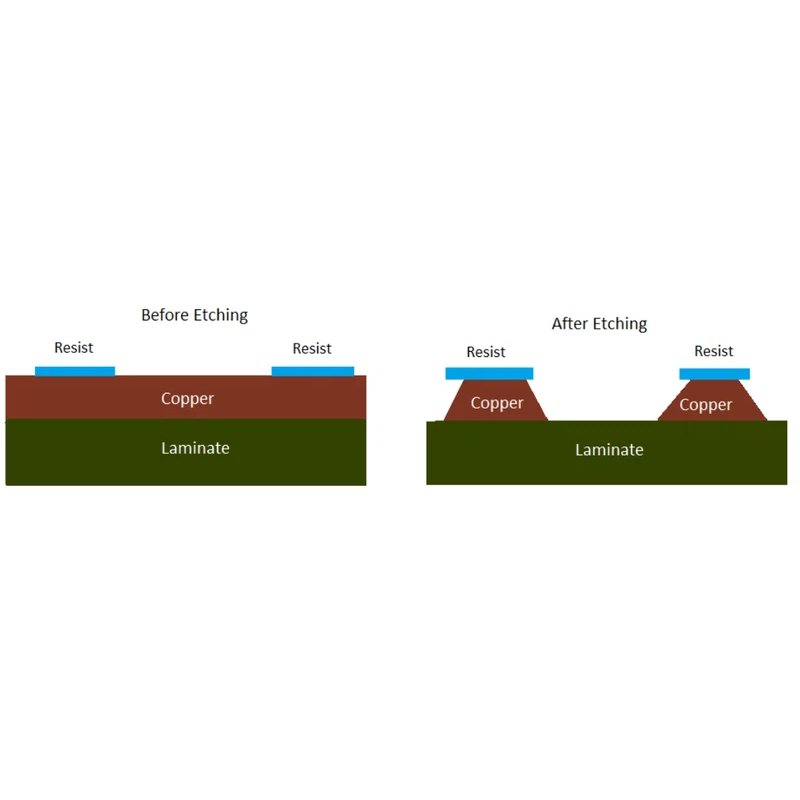

Wet etching uses liquid chemical solutions to dissolve exposed material. A mask (photoresist or hard mask) protects regions that must remain, and the exposed areas are attacked by the etchant. Wet etching is typically isotropic, meaning it removes material in all directions at roughly the same rate. That makes it fast and simple for bulk removal, oxide stripping, or cleaning, but it also produces undercutting beneath the mask that limits minimum feature sizes and verticality.

Common wet etch chemistries and uses:

- Acid etchants (e.g., HF for silicon dioxide, HNO₃ for certain metals) — oxide removal, metal surface preparation.

- Alkaline etchants (e.g., KOH, TMAH) — silicon anisotropic etching for MEMS cavities and bulk micromachining.

- Electrochemical etching — controlled material removal in metals using applied voltage.

- Spray or immersion baths — PCB trace etching, large area thin-film removal, or cleaning prior to plating.

Strengths: low capital cost, high throughput for large areas, smooth surface finish, straightforward chemistry control.

Limitations: isotropic profiles (undercut), limited ability for sub-micron features, hazardous chemical waste that requires neutralization and disposal.

How dry etching works

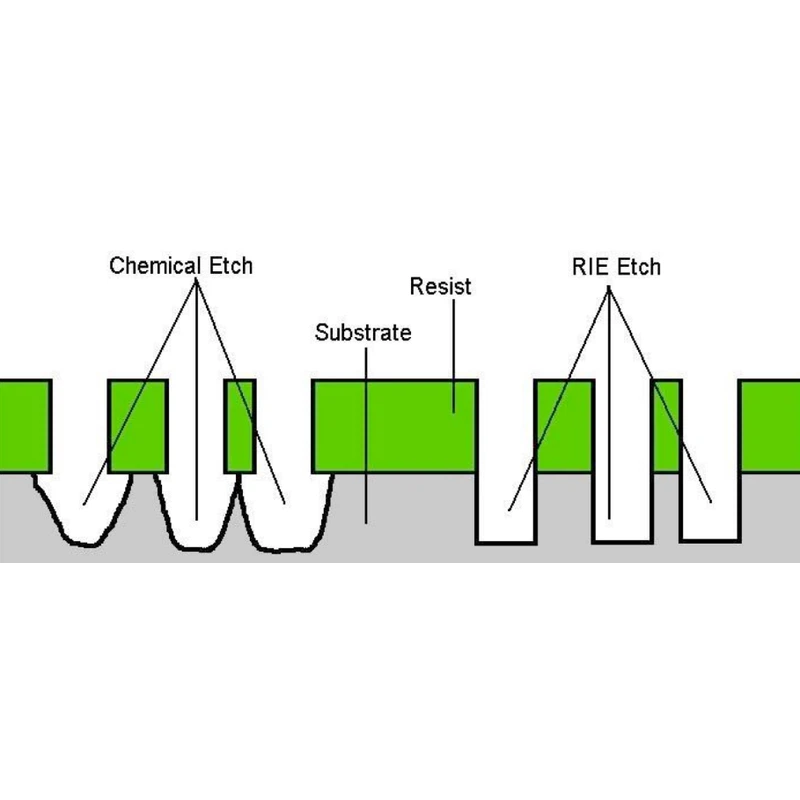

Dry etching uses ionized gases (plasma) in a vacuum reactor to remove material either chemically, physically, or through a combination. Reactive ion etching (RIE) couples chemically reactive species with directional ion bombardment to achieve anisotropic, vertical profiles with excellent pattern fidelity. Deep RIE (DRIE) variants (e.g., Bosch process) alternate etch/passivation cycles for very high-aspect-ratio trenches common in MEMS.

Common dry etch variants:

- Plasma etching — chemically reactive radicals remove materials (good for dielectrics and polymers).

- Reactive Ion Etching (RIE) — chemical + directional physical removal for anisotropic features.

- Deep RIE (DRIE) — specialized for deep, vertical silicon trenches.

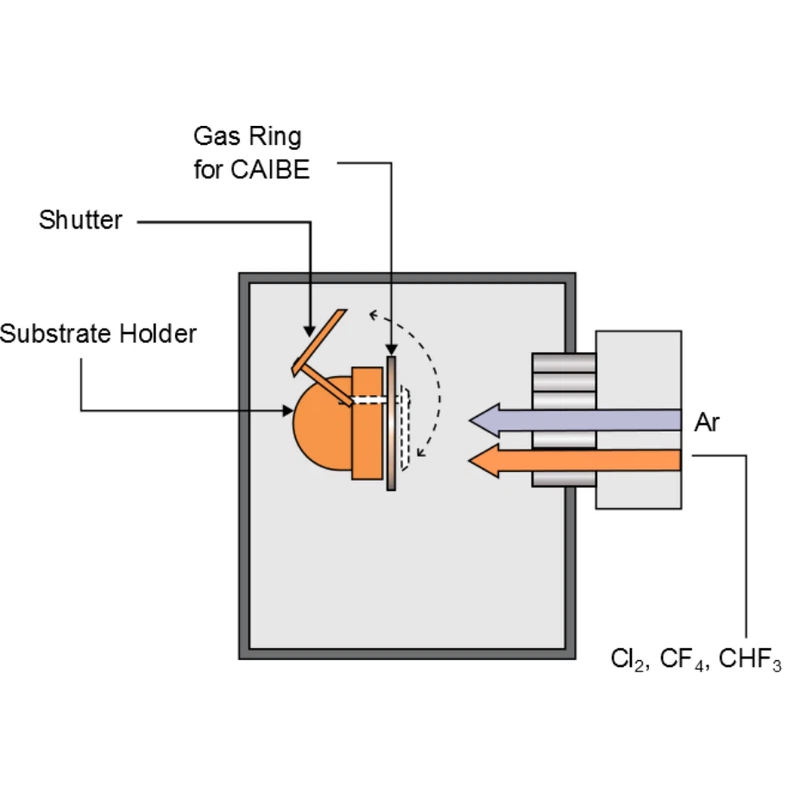

- Ion Beam Etching (IBE) / sputter etching — physical sputtering for metals and optical coatings where selectivity is less critical.

Strengths: high precision and anisotropy, minimal undercut, submicron capability, excellent control over sidewall angle and surface topology.

Limitations: higher equipment and operating costs, slower throughput for large areas, potential for ion damage or surface roughness if process not optimized.

Key performance parameters to consider

When you compare wet vs dry etch for an application, evaluate these metrics:

- Etch rate — how quickly material is removed; influences cycle time.

- Selectivity — etch rate of target material vs mask/underlayer; critical for pattern fidelity.

- Anisotropy — vertical vs lateral etch profile; governs achievable feature geometry.

- Uniformity — across-wafer or across-panel consistency.

- Surface finish — roughness or redeposition that affects bonding or coating.

- Repeatability & process control — ability to reproduce results batch after batch.

Typical applications and when to choose which

Use wet etching when:

- You need cost-effective oxide or metal strip on large areas.

- Surface smoothness is important and feature geometry is tolerant (PCBs, cleaning, bulk micromachining of noncritical features).

- Throughput and low CAPEX are priorities.

Use dry etching when:

- You require high-aspect-ratio trenches, vertical sidewalls, or sub-micron feature sizes (semiconductors, MEMS, microfluidics).

- Selectivity and profile control are critical to device function.

- You must avoid chemical immersion of sensitive assemblies.

Equipment, environment, and safety notes

Wet etch systems are simpler but generate chemical effluent that must be neutralized and treated. Proper fume handling, material compatibility, and chemical storage procedures are essential.

Dry etch uses vacuum chambers, RF power, and toxic gases (e.g., Cl₂, CF₄, SF₆). They require gas delivery safety systems, scrubbers or abatement units, and trained personnel for etch recipe tuning and preventive maintenance.

From a regulatory standpoint, both processes demand strict controls. At Plantmetal we maintain documented safety protocols, chemical handling training, and environmental controls to ensure compliance and repeatability.

Practical selection workflow

At Plantmetal our engineering workflow blends design intent with manufacturability:

- Define functional requirements — critical dimensions, sidewall tolerance, surface roughness, and throughput targets.

- Material assessment — what’s being etched (Si, SiO₂, metals, polymer), and how it reacts to common chemistries.

- Prototype screening — quick pilot runs using both wet and dry variants where feasible to evaluate profile and surface quality.

- Process optimization — tune concentration/temperature for wet etch, or gas mix/pressure/RF bias for dry etch to hit specs.

- Qualification & scale-up — statistical process control, FAI (First Article Inspection), and batch traceability before large runs.

Quality control and inspection

Successful etch processes must be validated with:

- Metrology: profilometry, SEM imaging for sidewall and undercut checks, and thickness metrology.

- Electrical tests when etching impacts conductive layers.

- Surface analysis: XPS or contact angle for chemical residue checks when adhesion or coatings follow.

- Statistical process control to monitor etch rate drift or gas flow anomalies over time.

Environmental and lifecycle considerations

Both etch families have sustainability impacts. Wet etch produces liquid waste and salts that must be treated. Dry etch reduces liquid effluent but relies on fluorinated gases that require abatement systems. At Plantmetal we design processes to minimize waste, recover and reuse where possible, and ensure proper abatement to satisfy both client and regulatory expectations.

Real-world examples

- PCB manufacture: wet etch for copper patterning is still standard due to throughput and cost.

- MEMS accelerometers: DRIE yields deep silicon trenches with tight verticality not feasible with wet KOH without crystal orientation constraints.

- Optical thin-film patterning: low-damage ion beam etching is used for high-precision coatings.

- High-volume packaging: wet etch for oxide strip followed by surface treatment before plating.

Bottom line and recommendation

There’s no universal “better” option. The correct choice depends on part geometry, material, tolerance, throughput, and total cost of ownership. If you need smooth batch processing and lower CAPEX, wet etch is attractive. If your design demands sub-micron control, vertical sidewalls, or MEMS features, dry etch is the right tool despite higher equipment cost.

At Plantmetal we combine both approaches in our process toolbox. Our engineers will assess your design, run feasibility trials, and deliver a production plan that balances performance, cost, and schedule.

If you’d like, send us your drawings and process requirements and we’ll propose an etching strategy that meets your targets for yield, quality, and manufacturability. Plantmetal stands ready to provide custom service, high-quality process development, and reliable manufacturing to bring your project from prototype to volume production.