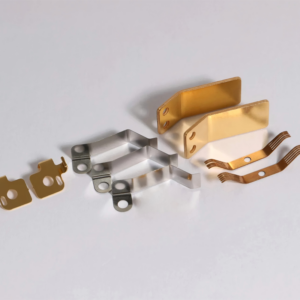

Stamped Electrical Terminals and Contacts

Custom Silver Plating Metal Terminal And Connectors for Electronic Industry Supplier

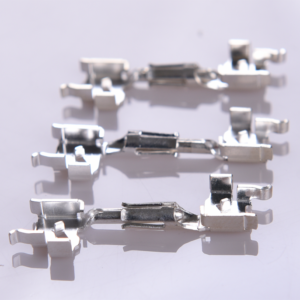

Metal terminals and connectors are vital for reliable electrical connections, transferring power seamlessly from sources to devices. These components, crafted using advanced progressive stamping techniques, guarantee precision, durability, and performance. Terminals are securely attached to wires through crimping or soldering, ensuring compatibility with pins, posts, or other terminals. Unlike splice connectors, terminals offer a single conductor with a strong mechanical attachment.

We specialize in custom solutions to meet diverse OEM requirements, delivering tailored designs and expert manufacturing for any application. Contact us today to discuss your custom metal terminal and connector needs!

Our Manufacturing Capabilities

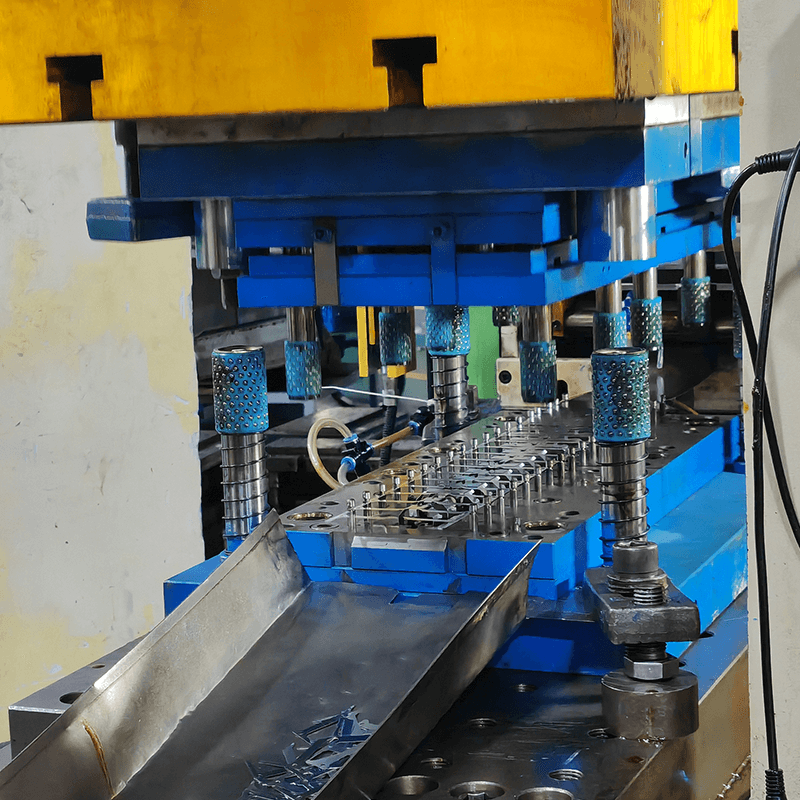

Progressive Metal Stamping

Progressive metal stamping is a precise sheet metal fabrication process that utilizes specialized stamping equipment to sequentially shape or separate metal sheets through a series of dies. This method allows for efficient production of high-quality, complex metal parts with tight tolerances and minimal waste.

Stampaggio profondo

Deep drawing offers high precision, tight tolerances, and an efficient process for manufacturing custom metal parts with complex shapes. It is ideal for creating high-quality, durable components across various industries.

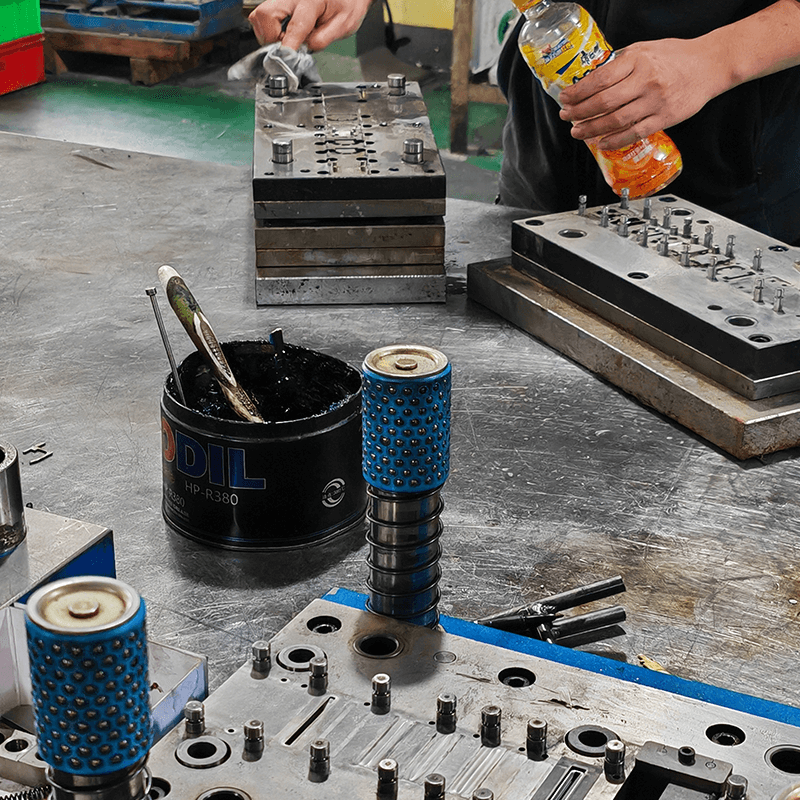

Tool & Die Manufacturing

Tool & die manufacturing is a precision process that shapes raw materials using custom tools and dies, enabling efficient production of high-quality metal components. The quality of the tools and dies is essential for accuracy and durability. This guide offers key insights to help you understand your custom metal needs and select the right tool & die suppliers.

Processi Secondari

We provide a wide range of secondary processes, including nickel plating, silver plating, heat treating, and electropolishing, to deliver the final touches your metal components require. Our one-stop solution ensures each part meets our strict quality standards.

Informazioni di Base

Categoria |

Dettagli |

| Personalizzazione | Calorosamente Benvenuti |

| Application Field | Electronics, Automotive Parts, etc. |

| Raw Material | Rame |

| Finitura Superficiale | Silver Plating, Gold Plating, Nickel Plating, etc. |

| Sample Lead Time | 5-40 Days (Depending on the Product) |

| Accessories Application | Electronic, Electrical |

| Formato di Disegno | Software per Disegni 2D e 3D |

| Controllo Qualità | 100% Inspection Before Shipment |

| Metodo di Spedizione | FOB, CIF, DDP, EXW, and More |

| Pacchetto di Trasporto | Blister Packaging, Poly Bag, Foam, Wood Box/Custom |

| Certificazione | IATF 16949, ISO 9001 |

| Capacità di Produzione | 100,000,000 PCS/Year |

Benefits of Metal Terminals and Connectors

1. Superior Conductivity

2. Corrosion Resistance

3. Enhanced Durability

4 .Improved Solderability

One-stop Services From Plantmetal

1. NDA Agreement

2. 3D Drawing Confirmation

3. DFM Confirmation

4. Prototyping

5. Trial Tooling

6. Mass Tooling

7. Metal Stamping Production

8. QC Inspection & Packaging

9. Warehouse and Logistics

10. After-Sales Service

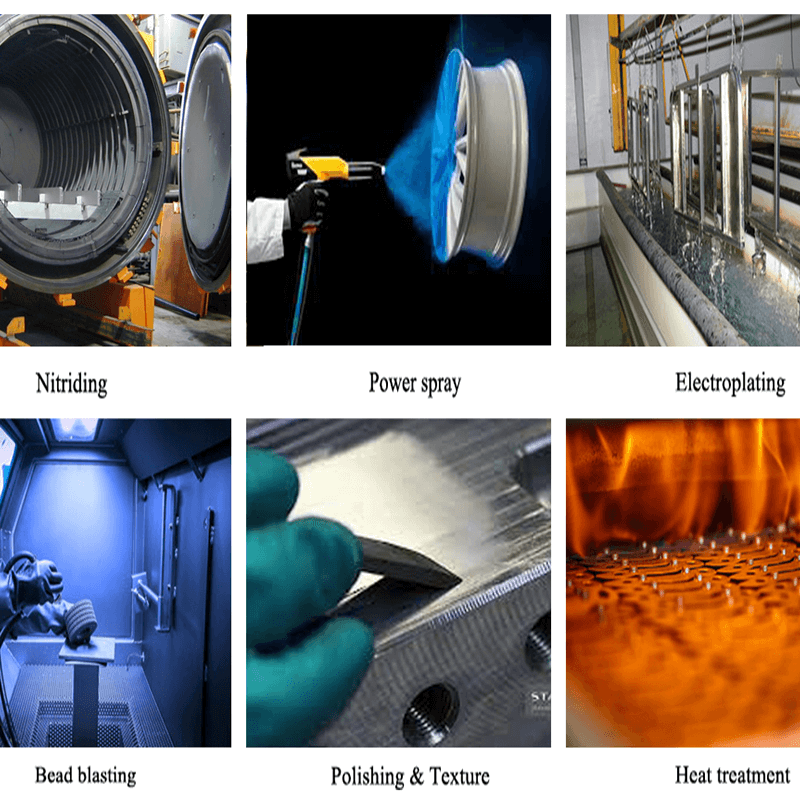

Opzioni di Trattamento Superficiale

Our metal terminals and connectors come with various surface treatment options, including silver, gold, and nickel plating etc. These treatments improve conductivity, corrosion resistance, and performance, offering tailored solutions for your needs.

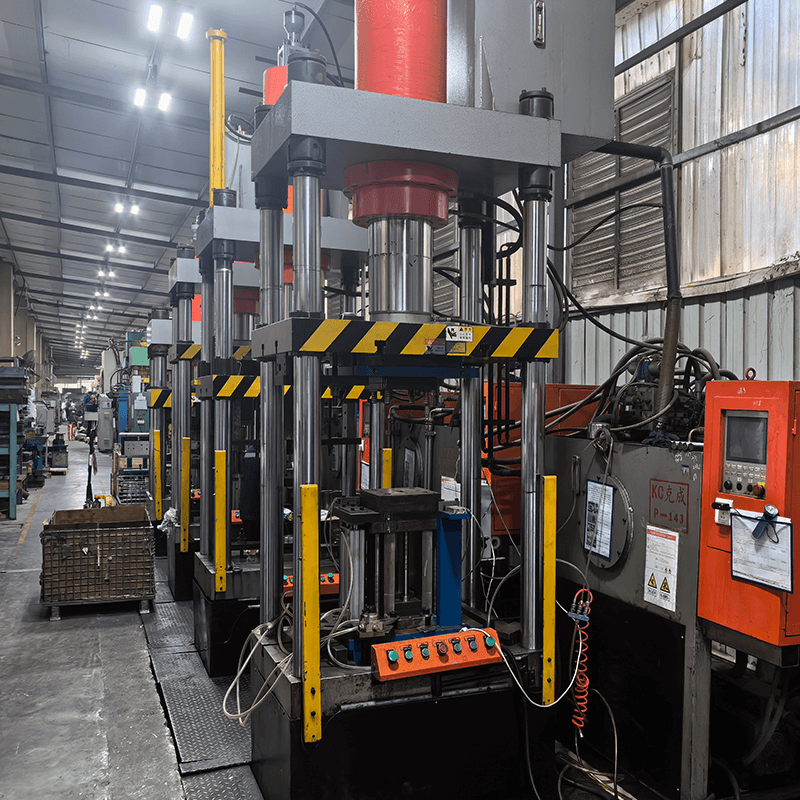

Our Factory

We operate advanced facilities equipped with 25 punch presses (25 to 300 tons), precision wire EDM machines, grinding equipment, welding tools, ultrasonic cleaning systems, and state-of-the-art plating facilities offering electroplating, zinc plating, nickel plating, and anodizing. Our quality management system, certified to IATF16949 and ISO9001 standards, integrates in-line/off-line camera vision systems, sensor technology, and CMM (Coordinate Measuring Machines) for precise inspection. These capabilities, combined with rigorous quality control, ensure our metal terminals and connectors meet the highest standards of durability, precision, and zero defects.

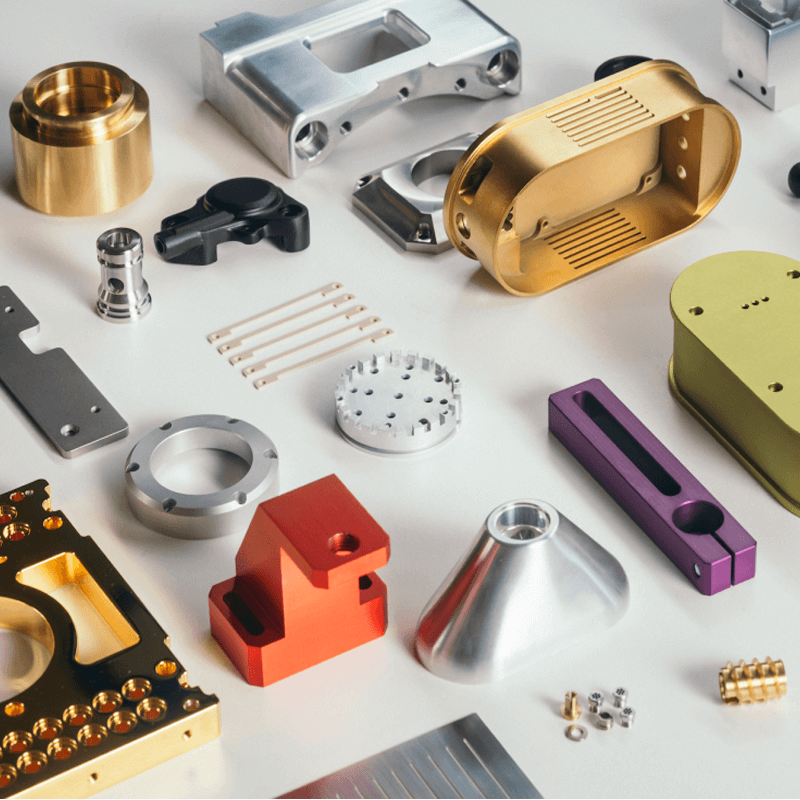

Custom Parts Gallery

Industries Served

Custom stamped metal terminals and connectors play a vital role across various industries. In the consumer electronics sector, they ensure reliable power and signal transmission in devices like smartphones and appliances. In automotive applications, they are integral to engine control modules, infotainment systems, and safety systems, providing stable connections in demanding environments. These connectors are also crucial in industrial automation, telecommunications, medical equipment, aerospace, and energy sectors, supporting high-performance, durable electrical connections in equipment such as PLCs, routers, diagnostic tools, avionics, and renewable energy systems. These connectors meet strict industry standards, ensuring reliability and safety in critical applications.