In the world of manufacturing, the materials used in production can make or break a product’s performance, cost-effectiveness, and durability. One material that has earned its place as a favorite for many industries is aluminum. Known for its lightweight, strength, and resistance to corrosion, aluminum has proven to be a go-to choice for a wide range of applications. When it comes to manufacturing complex shapes, deep-drawn aluminum parts stand out as a preferred solution, offering numerous benefits across industries such as automotive, aerospace, and medical devices.

At Plantmetal, we specialize in high-precision deep-drawn aluminum manufacturing, offering our clients a one-stop service from design to production. In this blog, we will explore the advantages of deep-drawn aluminum parts, the process behind creating them, and why this method has become a standard for quality in numerous industries.

What Are Deep-Drawn Aluminum Parts?

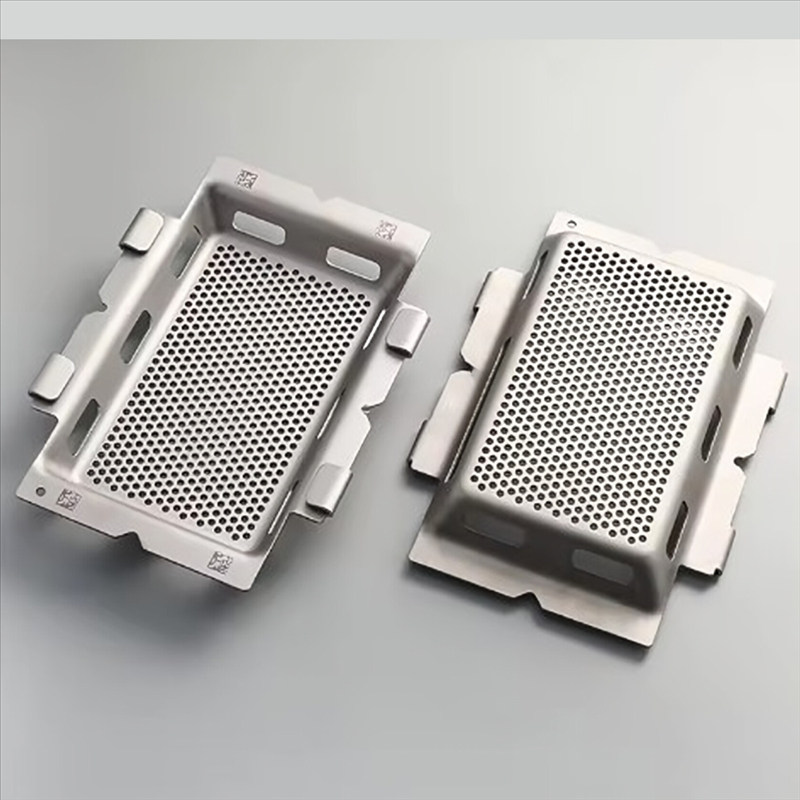

Deep drawing is a metal forming process used to create complex, hollow aluminum parts. This process involves pulling a flat piece of aluminum sheet, known as a blank, into a die cavity. By applying force, the material is stretched and compressed into a three-dimensional part with the desired shape and dimensions.

In deep-drawn aluminum, the end product can vary in shape and complexity. These parts are typically used in applications that require high strength, low weight, and excellent durability. Some examples include automotive panels, aerospace components, and medical device enclosures.

Advantages of Deep-Drawn Aluminum Parts

1. High Strength-to-Weight Ratio

One of the biggest reasons manufacturers turn to aluminum for deep-drawing applications is its exceptional strength-to-weight ratio. Aluminum is much lighter than steel, yet it can offer comparable strength, making it the ideal choice for industries where weight reduction is crucial. This is especially important in industries like aerospace and automotive, where reducing weight can lead to improved fuel efficiency, increased payload capacity, and better performance.

2. Corrosion Resistance

Unlike many metals, aluminum naturally resists corrosion due to the formation of an oxide layer on its surface. This layer protects the material from rust and other environmental damage, making it an excellent choice for parts that need to endure exposure to harsh conditions. Aluminum’s corrosion resistance eliminates the need for extensive treatment or coatings, reducing production costs and improving longevity.

3. Recyclability and Sustainability

Aluminum is 100% recyclable without loss of quality, making it a sustainable option for manufacturers looking to reduce their environmental footprint. The ability to recycle aluminum helps lower material costs and lessens the demand for new raw materials. As companies and industries strive for more sustainable manufacturing practices, deep-drawn aluminum parts align with these goals by providing a high-quality product with minimal environmental impact.

4. Durability and Impact Resistance

Deep-drawn aluminum parts are renowned for their durability. The process of deep drawing strengthens the material, increasing its ability to withstand physical impacts, making it ideal for industries where part durability is essential. In the automotive industry, for example, deep-drawn aluminum body panels are highly resistant to dents and dings, offering a longer-lasting, more aesthetically pleasing surface.

5. Cost-Effectiveness for Low and High-Volume Production

Deep-drawn aluminum parts offer significant cost advantages. Not only are aluminum materials affordable, but the deep drawing process itself is highly efficient. This process allows for high precision and minimal material waste, making it an economical choice for both low- and high-volume production runs. Furthermore, the reduced need for post-production treatments and coatings adds to the overall savings.

The Deep Drawing Process

Step 1: Preparing the Aluminum Blank

The deep-drawing process begins with a flat aluminum sheet or “blank.” This blank is cut into the desired size and shape for the specific part being created. The size and thickness of the blank play an important role in determining the final shape of the part.

Step 2: Drawing into the Die

The blank is then placed into a die cavity. The die is designed to shape the material into the desired form, whether it’s cylindrical, conical, or another complex shape. Using a punch, the operator applies force to pull the aluminum into the die. This process stretches and compresses the material, ensuring it conforms to the die’s design.

Step 3: Redrawing

In many cases, deep-drawn aluminum parts undergo a second drawing process. This step involves placing the partially formed part into another die and applying additional pressure to further shape the material and reduce its diameter while increasing its length. This ensures the part meets the required dimensions.

Step 4: Finishing

After the deep drawing process is complete, the part is often subjected to finishing steps such as trimming, deburring, and surface treatments. These processes help ensure the final product meets the desired aesthetic and functional specifications.

Why Choose Plantmetal for Deep-Drawn Aluminum Parts?

At Plantmetal, we specialize in the precision manufacturing of deep-drawn aluminum components. As an experienced manufacturer, we offer our clients high-quality, custom-made parts that meet the most stringent standards. Here are some reasons why you should consider partnering with us for your aluminum manufacturing needs:

1. High Precision Manufacturing

We utilize state-of-the-art equipment and techniques to ensure that every deep-drawn aluminum part is produced with the highest level of precision. Our experienced engineers and technicians guarantee that each part meets the required specifications and performs consistently throughout its service life.

2. Customization and OEM Service

We understand that every customer has unique needs, and we offer tailored solutions to meet those specific requirements. Whether you need a custom-designed part or a high-volume production run, our team works closely with you to ensure that your vision is realized. With our OEM services, we provide parts that are fully compatible with your existing systems, ensuring seamless integration into your products.

3. One-Stop Service

At Plantmetal, we offer a one-stop service that includes design, prototyping, manufacturing, and finishing. This streamlined approach reduces lead times and ensures the highest level of quality control at every step of the process. With our full-service capabilities, we make the process easier for our customers by handling everything from concept to finished product.

4. Commitment to Sustainability

We believe in the importance of sustainable manufacturing practices, which is why we prioritize the use of recyclable materials like aluminum. By choosing Plantmetal as your supplier, you’re partnering with a company that values environmental responsibility and offers products that are both high-quality and eco-friendly.

Conclusion

Deep-drawn aluminum parts offer a host of advantages for a wide range of applications, from automotive components to aerospace structures. The process of forming these parts allows for high precision, durability, and cost-effectiveness while maintaining aluminum’s natural strength and resistance to corrosion. At Plantmetal, we are committed to providing our clients with the highest-quality deep-drawn aluminum parts, backed by our OEM services, high precision manufacturing, and sustainable practices.

If you are looking for a reliable manufacturer of deep-drawn aluminum components, look no further. Contact Plantmetal today to learn more about our capabilities, request a free quote, or discuss your project requirements. Let us help you bring your vision to life with precision-engineered aluminum parts that meet your business needs.