When it comes to manufacturing high-precision metal parts, two methods often come into the conversation: Electrical Discharge Machining (EDM) and traditional CNC machining. As a manufacturer at Plantmetal, we work with a wide range of clients across various industries to produce complex, high-precision metal stamping parts. The choice between EDM and CNC machining can significantly impact the quality, cost, and timeline of your project. Understanding the strengths of each process is crucial to making the right decision for your specific part requirements.

In this blog, we will dive into the key differences between EDM and CNC machining, explain the advantages of each process for precision metal parts, and explore how we help clients at Plantmetal choose the best method for their needs. By the end of this article, you’ll be equipped with the knowledge to determine which approach will provide the best results for your project.

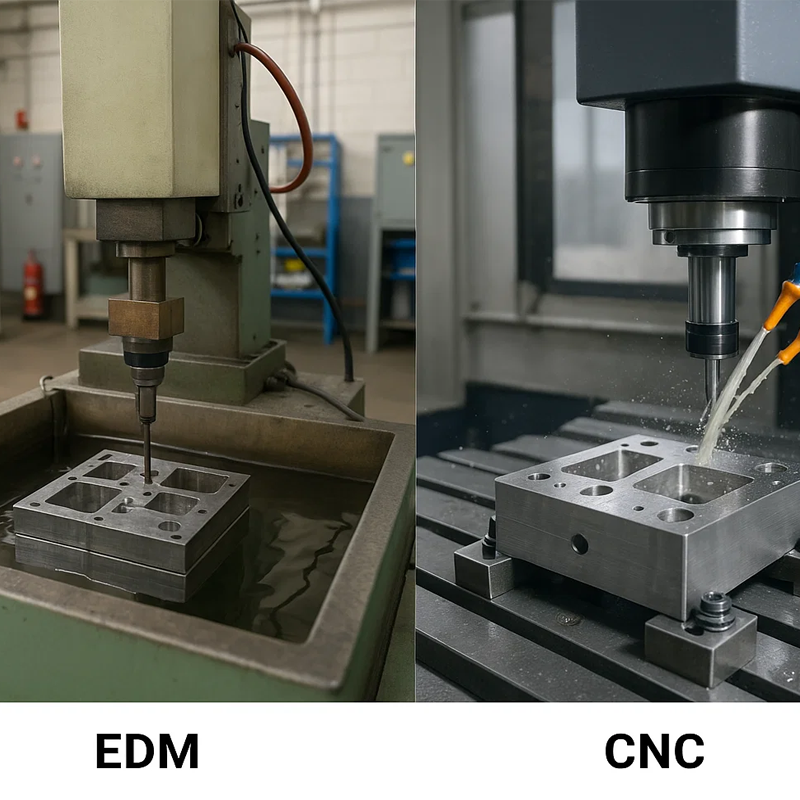

What’s the Difference Between EDM and CNC Machining for Precision Parts?

When precision is the priority, both EDM and CNC machining can deliver exceptional results. However, each method has its own unique capabilities and limitations depending on the material, complexity, and volume of parts required. At Plantmetal, we assess these factors to determine the most effective production approach.

Electrical Discharge Machining (EDM)

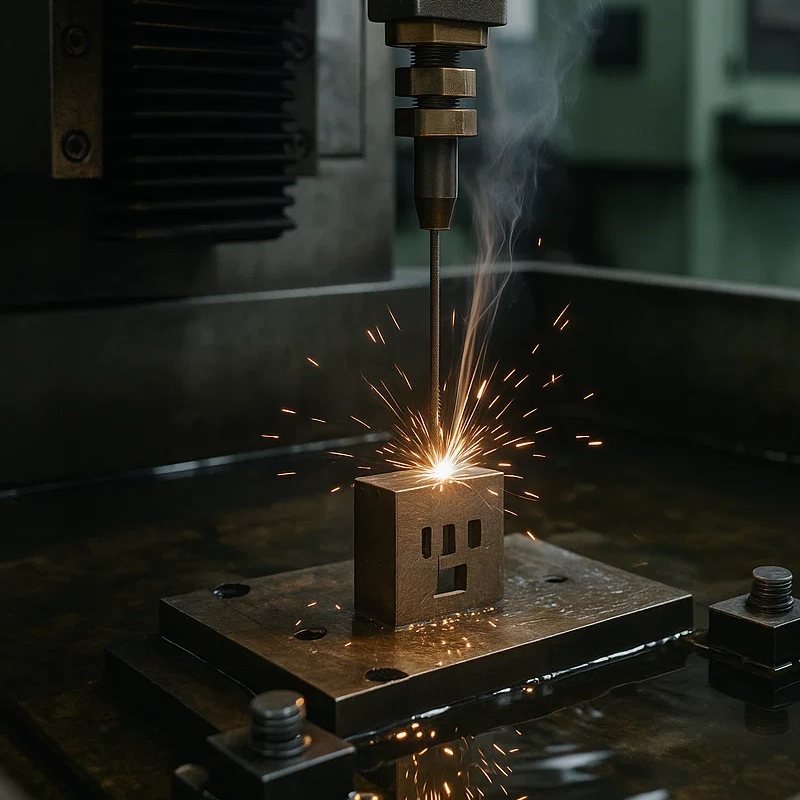

EDM is an advanced machining technique that uses a series of electrical discharges to erode material from a workpiece. It’s particularly effective when working with hard metals and complex geometries. Here’s how EDM stands out:

- Precision: EDM is renowned for its ability to achieve incredibly tight tolerances, often down to 0.001mm (1 micron). This level of accuracy makes it ideal for parts that require intricate internal features, sharp corners, or fine details that cannot be achieved using traditional cutting methods.

- Hard Materials: EDM excels when working with extremely hard materials, such as tool steels, Inconel, titanium, and carbide. Unlike traditional CNC machines, EDM doesn’t rely on physical cutting tools, which means it can erode tough materials without compromising the material’s integrity.

- No Tool Pressure: Since EDM is a non-contact process, it doesn’t apply any pressure to the material. This is beneficial for parts that are delicate, thin-walled, or easily deformed. Additionally, because there is no mechanical stress, EDM can create intricate internal features like cooling channels or small cavities that would be impossible with CNC machining.

CNC Machining

CNC machining, or Computer Numerical Control machining, uses pre-programmed computer software to control the movement of a machine tool. CNC machines can handle a variety of materials and are known for their versatility, speed, and repeatability. Here’s why CNC machining is often the go-to choice for precision metal stamping:

- Speed: CNC machining is typically faster than EDM, especially for high-volume production runs. The process is automated and highly efficient, which makes it ideal for larger quantities of parts where precision and speed are critical.

- Versatility: CNC machining can handle a wide range of materials, including metals like aluminum, stainless steel, and brass, and is suited for both simple and complex parts. Whether the part has external contours or requires multi-axis machining, CNC machines can achieve high precision with a variety of cutting tools.

- Repeatability: One of the biggest advantages of CNC machining is its repeatability. Once a program is proven, CNC machines can produce thousands of identical parts, each with the same tight tolerances. This makes it a perfect choice for large production runs where consistency is essential.

- Tool Pressure: While CNC machining offers impressive precision, it does apply mechanical force through cutting tools. This can sometimes lead to micro-deflections or vibrations, which may slightly affect the part’s precision, especially for very fine features or hard materials.

Which Process Is Best for High-Precision Metal Stamping Parts?

The choice between EDM and CNC machining depends on several factors, including the material, part complexity, production volume, and tolerance requirements. Here’s a breakdown of when each process is best suited for precision metal stamping parts:

When to Choose EDM

- For Hard Materials: If you’re working with extremely hard materials such as Inconel, hardened steel, or titanium, EDM is often the better choice. Its ability to machine these tough materials without causing deformation or excessive wear on tooling is unmatched.

- For Complex Geometries: If your part requires intricate internal features, such as small holes, deep pockets, or complex cooling channels, EDM can achieve this level of detail where CNC machining may struggle.

- When Precision Is Critical: For parts that demand tolerances of 0.001mm or less, such as aerospace or medical components, EDM is the method of choice. The process eliminates tool pressure and mechanical stress, ensuring the highest levels of accuracy.

When to Choose CNC Machining

- For Faster Turnaround: If speed is essential, particularly for larger production runs of parts with complex external features, CNC machining is the way to go. It’s faster than EDM for high-volume orders and offers excellent precision.

- For Simpler Shapes: CNC machining is ideal for parts with simpler external geometries or straight cuts. It’s a versatile option for many industries, from automotive to consumer electronics, offering quick results with high repeatability.

- For Cost-Effective Production: CNC machining is often more cost-effective for producing medium to large quantities of parts. The efficiency of the process and the lower tool wear compared to EDM results in reduced overall costs for these types of orders.

The Advantages of CNC Machining and EDM for Precision

To help our clients make an informed decision, at Plantmetal, we thoroughly evaluate the unique needs of each project and provide tailored advice. Here’s a comparison chart to summarize when to use CNC or EDM:

| Caratteristica | 5-Axis CNC Machining | EDM |

|---|---|---|

| Best For | High-volume production, complex external features | Intricate internal features, hard materials |

| Velocità | Faster | Slower |

| Materiali | Aluminum, Steel, Titanium | Inconel, Tool Steel, Hardened Materials |

| Precision | High repeatability, tolerances around 0.005” | Highest precision, tolerances around 0.001mm |

| Cost | More cost-effective for high volumes | Higher setup costs but ideal for complex parts |

| Tool Pressure | Mechanical tool pressure applied | No tool pressure, ideal for delicate parts |

How Plantmetal Addresses Client Concerns During the Manufacturing Process

At Plantmetal, we understand that choosing the right machining method is not always straightforward. That’s why we take a collaborative approach, especially with clients who need high-precision metal stamping parts. For example, one of our recent clients, a company in the aerospace industry, needed parts that required extremely tight tolerances and had intricate internal features. After assessing their requirements, we recommended EDM due to the high precision needed for the internal features and the hard material being used.

We also worked closely with this client to help them navigate potential cost concerns. By using EDM for the most intricate features and CNC machining for the more straightforward aspects of the part, we were able to optimize the production process and keep costs manageable while maintaining the required precision. The result was a set of parts that met the client’s exact specifications without any compromise in quality.

Conclusion: Making the Right Choice for Your Precision Parts

At Plantmetal, our goal is to provide the best solutions for your high-precision metal stamping parts. Whether you need the extreme precision of EDM for intricate designs or the speed and efficiency of CNC machining for high-volume production, we have the expertise to guide you through the decision-making process.

If you’re unsure which method is right for your project, reach out to us for a consultation. Our experienced engineers will work closely with you to ensure that your parts meet all required tolerances and specifications, saving you both time and cost in the process. Let us help you find the best solution to bring your high-precision parts to life.