Description:

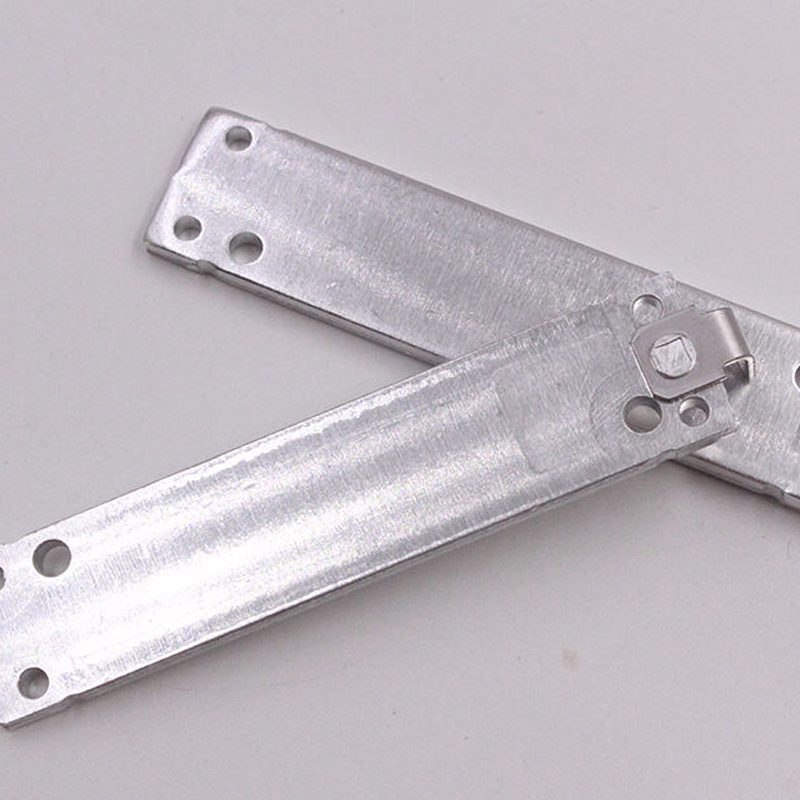

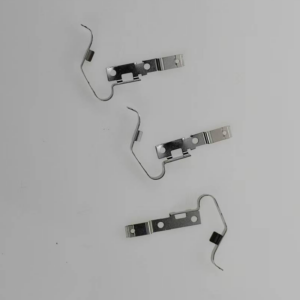

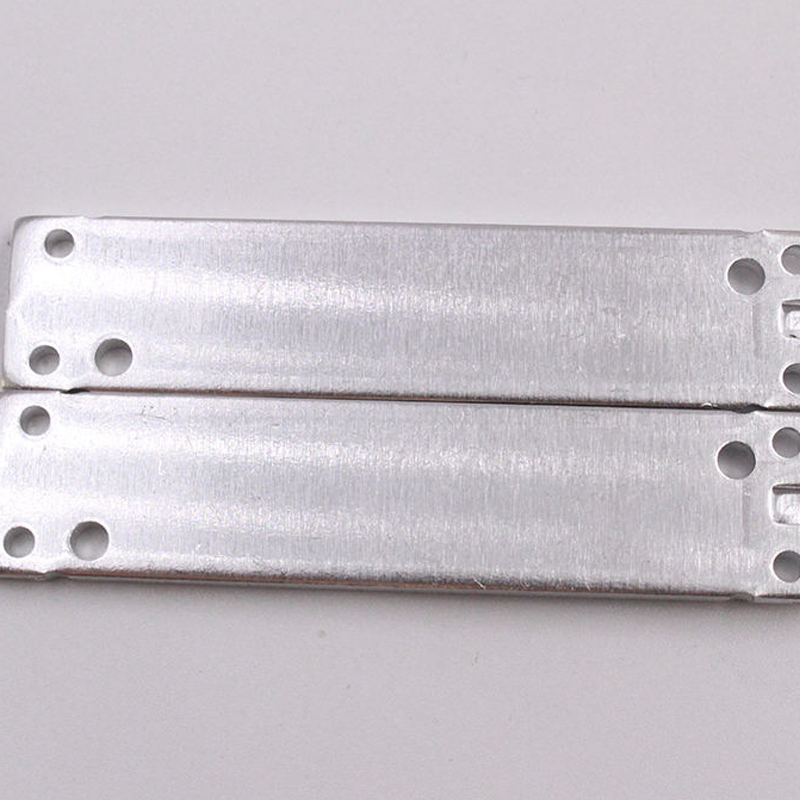

Our progressive die stamped brackets are engineered for precision and durability in demanding mechanical feeding systems. Manufactured from high-strength steel with tight tolerances, these brackets ensure reliable component mounting, alignment, and structural support in automated machinery. We offer comprehensive OEM services for custom designs and finishes.

Product Details:

-

Type: Progressive Die Stamping

-

Processing Type: Metal Forming & Fabrication

-

Material: Carbon Steel (Q235, SS400), Stainless Steel (SUS304), Spring Steel (SK5), Aluminum

-

Mould: Custom Progressive Dies (8-20 stations)

-

Surface Processing: Zinc Plated, Nickel Plated, Powder Coating, Passivation

-

Fine Blanking: Precision Burr-Free Edges

-

Process: Stamping, Forming, Piercing, Bending

-

Industry: Automation Equipment, Packaging Machinery, Conveyor Systems, Medical Devices

-

Tolerances: ±0.05mm (standard), ±0.02mm (precision)

-

Customized: Fully Supported (Design to Production)

-

Color: Custom (RAL/Pantone Matched for coatings)

-

Transport Package: Custom (Anti-tarnish bags, Cartons, Pallets)

-

Specification: Customer Drawings & 3D Files Accepted

-

Trademark: OEM

-

Origin: Xiamen, China

Production Process:

-

Material Selection & Inspection: We select premium steel coils (carbon steel, stainless steel, or spring steel) based on required tensile strength, hardness, and corrosion resistance. Each batch undergoes material certification and incoming inspection.

-

Progressive Die Stamping: The coil is fed through a custom progressive die in a high-speed press. The die performs multiple operations (piercing, blanking, forming, bending) in successive stations to transform flat metal into a complete, complex bracket in a single pass.

-

Deburring & Surface Preparation: After stamping, parts undergo tumbling or vibratory finishing to remove micro-burrs and sharp edges, ensuring safety and preparing the surface for subsequent treatments.

-

Surface Treatment Application: Based on specifications, brackets receive surface treatment—such as electroplated zinc for corrosion resistance, nickel plating for wear resistance, or powder coating for aesthetic appeal and additional protection.

-

Precision Measurement & Quality Control: Each production batch is sampled for rigorous inspection using CMM (Coordinate Measuring Machine), optical projectors, and hardness testers to verify critical dimensions, hole positions, flatness, and coating thickness against engineering drawings.

-

Custom Assembly & Packaging: For turnkey solutions, we can perform secondary operations (tapping, welding, assembly) and package brackets in custom dividers or kits to prevent damage and facilitate easy integration into your assembly line.

Surface Treatment Options:

-

Electro-Zinc Plating (Blue/White/Yellow Chromate): Provides excellent corrosion resistance and a conductive surface at a competitive cost, ideal for indoor machinery components.

-

Nickel Plating (Electroless or Electrolytic): Offers superior wear resistance, hardness, and a smooth finish that reduces friction, suitable for high-wear contact points in feeding mechanisms.

-

Powder Coating: Delivers a thick, durable, and decorative finish in any color. It provides excellent chemical and abrasion resistance, perfect for brackets requiring both protection and brand-specific aesthetics.

-

Black Oxide/Phosphating: Creates a non-reflective, corrosion-resistant magnetite layer that retains lubricants and reduces galling, ideal for parts requiring precise mating and reduced light reflection.

Our Factory:

Our advanced metal stamping facility is equipped with a comprehensive range of machinery to handle complex bracket production. We operate 30+ high-precision punch presses (25 to 500-ton capacity) integrated with automated feeding and vision inspection systems. Our in-house tool and die department features CNC wire-cut EDM, CNC machining centers, and precision grinding equipment for manufacturing and maintaining complex progressive dies with micron-level accuracy.

To enhance part functionality and lifespan, we have dedicated surface treatment lines for electroplating (zinc, nickel) and a fully automated powder coating booth with a curing oven. Our quality assurance is supported by a metrology lab equipped with 3D CMM, contour projectors, coating thickness gauges, and salt spray test chambers.

This integrated setup—from raw material to finished, treated part—ensures we deliver structurally sound, dimensionally accurate, and reliably protected brackets that meet the rigorous demands of high-cycle mechanical feeding systems.