Selecting the correct cutting method is crucial for ensuring the efficiency and success of any project. At Plantmetal, we understand that the right cutting process can save time, reduce costs, and improve the quality of your finished products. However, choosing between cutting technologies like laser cutting, waterjet cutting, and plasma cutting can be a daunting task. Each method offers distinct advantages and drawbacks, depending on your material type, thickness, and precision requirements. In this blog, we will guide you through the differences between these cutting methods and help you determine the best option for your next project.

Why Cutting Method Selection Matters

In the world of manufacturing and production, choosing the wrong cutting method can lead to costly delays, quality issues, and project setbacks. For suppliers who rely on timely delivery and top-notch products, these issues can result in not only financial loss but also damage to long-term customer relationships. At Plantmetal, a leading manufacturing facility in China, we work closely with our clients to understand their needs and guide them toward the right cutting solutions for their specific requirements. By understanding the key differences between cutting methods, you can avoid costly errors and ensure that your project progresses smoothly from start to finish.

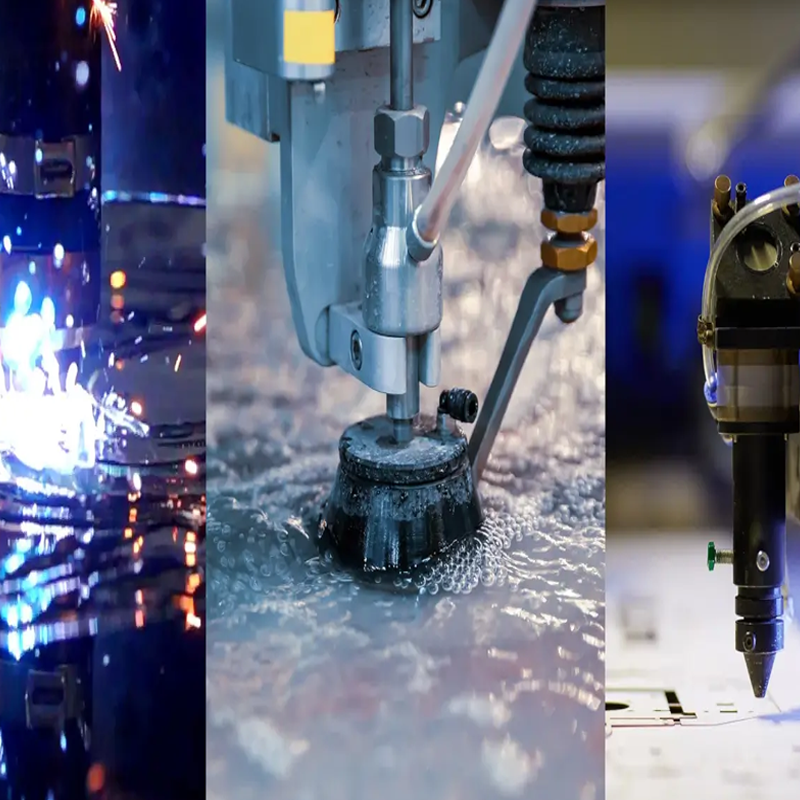

The right cutting method depends heavily on the materials you’re working with, the part’s desired thickness, and your speed and precision requirements. Let’s dive into the three most common cutting methods: laser cutting, waterjet cutting, and plasma cutting, and explore how each method performs in different scenarios.

Laser Cutting vs. Plasma Cutting: Precision vs. Cost

When it comes to cutting thick metal, plasma cutting is often the more cost-effective choice, but laser cutting offers superior precision. At Plantmetal, we frequently encounter customers who need to strike a balance between budget constraints and quality. One such client, Mark from Canada, reached out to us about his frustration with trying to find the right process for his parts. “I just need to know which process is right for my part. I can’t afford mistakes or delays,” he explained. This sentiment is common among manufacturers who depend on high-quality, defect-free parts but also have budget limitations.

Laser cutting uses a focused beam of light to achieve precise cuts on thinner materials (typically up to 20mm in thickness). It offers an unparalleled level of precision, with tolerances as tight as ±0.2mm, making it ideal for intricate parts that require tight fits, such as those found in the electronics and automotive industries. The heat-affected zone (HAZ) is minimal, meaning there is less chance of distorting the material or changing its properties.

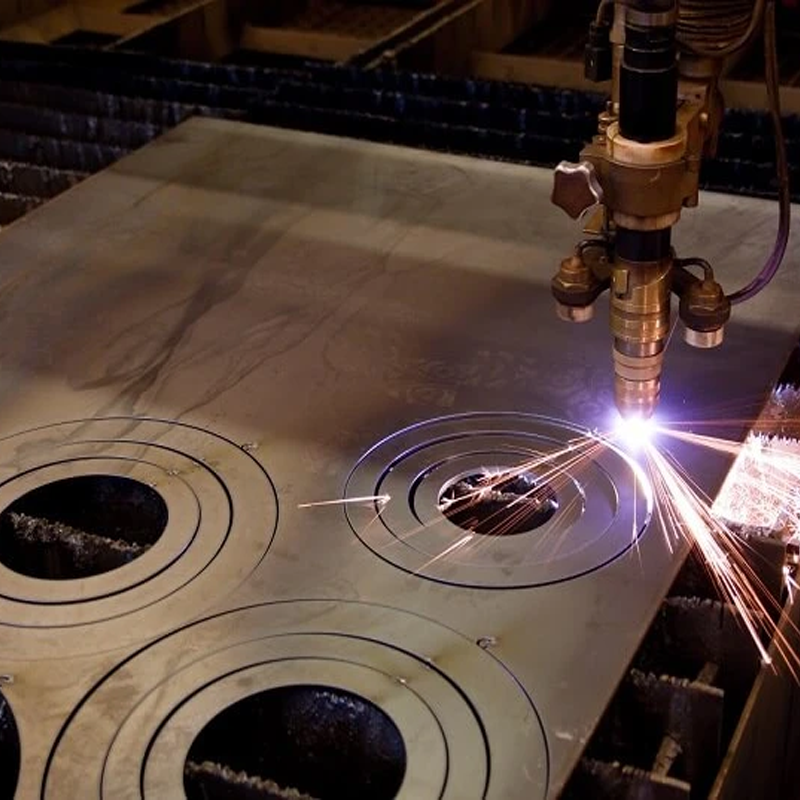

In contrast, plasma cutting uses superheated, ionized gas to slice through thicker materials, typically between 1mm to 120mm. While it is significantly faster and less expensive, plasma cutting sacrifices precision. It typically achieves tolerances of about ±1mm, and the heat generated can cause a larger HAZ, potentially altering the material’s properties. This may be a problem for clients who need parts to fit together precisely or require minimal post-cutting work. A customer of ours in the automotive sector initially chose plasma cutting for their bracket production, only to find that the holes weren’t precise enough, leading to additional costs for grinding and adjustments. For their next order, they opted for laser cutting, which offered higher precision, saving time and labor in the long run.

| Funcionalidade | Laser Cutting | Plasma Cutting |

|---|---|---|

| Precision | High (±0.2mm) | Low (±1mm) |

| Metal Thickness | Up to 20mm | 0mm to 120mm |

| Velocidade | Fast on thin materials | Fast on thick materials |

| Heat Affected Zone | Minimal | Significant |

| Best For | Intricate designs, tight tolerances | Thick conductive metals, cost-savings |

Laser Cutting vs. Waterjet Cutting: Heat vs. Versatility

When working with materials that are sensitive to heat or extremely thick, waterjet cutting is often the better option. Laser cutting, though fast and precise, is a thermal process, which means it uses heat to melt or vaporize the material. This makes it unsuitable for heat-sensitive materials, as it can cause warping, discoloration, or even release toxic fumes in the case of certain plastics.

Waterjet cutting, on the other hand, is a cold cutting process that uses high-pressure water mixed with an abrasive to cut through materials. Since it does not generate heat, it is ideal for cutting materials like plastics, composites, and thick metals that might be damaged by heat. At Plantmetal, we use waterjet cutting for applications requiring zero heat distortion, such as aerospace components or medical parts. In fact, one of our aerospace clients needed to cut titanium for a specialized project. Plasma cutting could have handled the thickness, but the heat would have compromised the material’s properties. Waterjet cutting was the only viable solution.

Waterjet cutting also offers higher precision compared to plasma cutting, typically achieving tolerances as tight as ±0.1mm, making it a great choice for prototyping and small-batch production where quality is a top priority. However, the trade-off is that waterjet cutting is slower than laser cutting, which makes it less ideal for high-volume production.

| Funcionalidade | Laser Cutting | Waterjet Cutting |

|---|---|---|

| Processo | Thermal (Heat) | Mechanical (Erosion) |

| Applicable Materials | Metals, some plastics, wood | Almost any material |

| Heat Affected Zone | Yes (small) | No |

| Precision | High (±0.2mm) | Very High (±0.1mm) |

| Best For | Speed, mass production | Heat-sensitive materials, very thick materials |

Plasma Cutting vs. Waterjet Cutting: Speed vs. Quality

When cutting very thick metal, both plasma and waterjet can get the job done. Plasma cutting, which uses a high-temperature arc of ionized gas, is ideal for conductive metals like steel. It’s fast and cost-effective but produces a rougher edge with some dross, meaning that a secondary operation, such as grinding, is often necessary to clean up the edges.

Waterjet cutting is a slower, more expensive process, but it offers superior edge quality and precision. Its cold cutting process prevents any thermal damage to the material, which is particularly valuable for delicate or heat-sensitive materials. While waterjet cutting is more versatile in terms of the range of materials it can process, it is much slower than plasma cutting, making it more suitable for lower-volume runs or applications where precision and edge quality are paramount.

| Funcionalidade | Plasma Cutting | Waterjet Cutting |

|---|---|---|

| Processo | Thermal (Heat) | Mechanical (Erosion) |

| Material Scope | Conductive metals only | Nearly any material |

| Precision | Low (±1mm) | Very High (±0.1mm) |

| Edge Finish | Good, some dross | Excellent, smooth |

| Best For | Cost-effective thick metal cutting | Precision cutting on any material, no HAZ |

Conclusion: Making the Right Choice

At Plantmetal, we believe in helping our clients make informed decisions that align with their needs. The right cutting method depends on various factors, including the material, thickness, required precision, and your budget. Whether you’re working with thin metals, heat-sensitive materials, or thick metals, understanding the strengths and limitations of each cutting method will allow you to choose the best option for your project.

As a leading manufacturing facility and supplier in China, we are dedicated to providing the highest quality cutting services tailored to your specifications. If you’re unsure which method is best for your parts, contact us today. Our team of experts at Plantmetal is ready to guide you through the process and ensure that your project is a success from start to finish. Choose the right cutting method, save time, reduce costs, and enjoy the peace of mind that comes with high-quality manufacturing.