Visão Geral

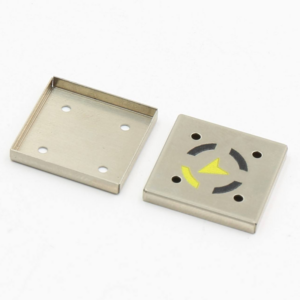

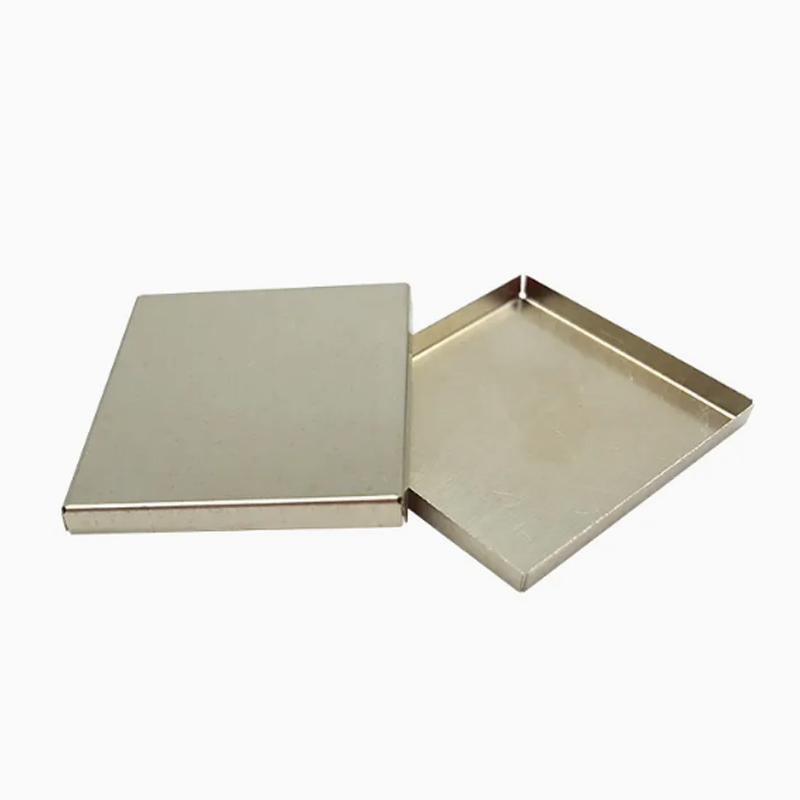

As nossas tampas de proteção em aço inoxidável, revestidas com eletroforese e moldadas a fundo, são projetadas para proporcionar uma proteção robusta contra EMI/RFI, proteção mecânica e um acabamento resistente à corrosão para placas de circuito impresso em eletrónica industrial, telecomunicações, médica e aeroespacial. Fabricadas a partir de aço inoxidável de alta qualidade (SUS301 / SUS304 / SUS316L) utilizando técnicas de moldagem profunda de precisão e estampagem progressiva, cada tampa de proteção é acabada com uma camada uniforme de eletroforese (e-coat) que oferece excelente resistência à corrosão, propriedades dielétricas consistentes e uma superfície preparada para revestimentos secundários ou juntas. Oferecemos serviços OEM de ponta a ponta — fabrico de ferramentas, prototipagem, produção em alta volume, usinagem secundária, montagem e controlo de qualidade rigoroso — para fornecer soluções de proteção otimizadas para aplicações que atendem aos requisitos elétricos, mecânicos e ambientais.

Características

| Atributo | Detalhes |

|---|---|

| Local de Origem | Xiamen, China |

| Marca | Marca Branca / OEM |

| Material Base | Aço Inoxidável SUS301 / SUS304 / SUS316L (outras ligas sob consulta) |

| Espessura do Material | 0,3 – 3,0 mm (personalizável) |

| Processo | Estampagem profunda, Estampagem progressiva,Corte a laser,Dobragem/formação CNC,Viragem,Soldadura por pontos |

| Revestimento Eletroforético | E-coat (deposição eletrofótica), espessura típica de 5–25 μm |

| Cor / Acabamento da Revestimento | Acabamento mate / satinado padrão; acabamentos RAL personalizados ou texturizados disponíveis. |

| Eficácia de Blindagem | Típico de 40 a 80 dB (dependente da aplicação; até > 80 dB com montagens vedadas/com junta) |

| Tolerância | ±0,01 mm (áreas funcionais; tolerância geral ±0,05 mm) |

| Tratamento de Superfície | Passivação, eletropolimento, jateamento de microesferas ou tratamentos pós-personalizados. |

| Certificação | ISO 9001:2015, IATF 16949 (opcional), RoHS, REACH |

| The translation of "Sample Lead Time" to Portuguese (Portugal) is "Prazo de Entrega da Amostra." | 5 a 10 dias úteis (peça de protótipo carimbada) |

| O prazo de produção | 15 a 35 dias úteis (dependente da ferramental) |

| MOQ | Flexível; prototipagem para suporte a altos volumes |

| Embalagem | Embalagem anti-corrosão, suportes em espuma, kits personalizados para montagem. |

Fabricação e Processos

- Ferramentação e Moldagem: Matrizes progressivas e ferramentas de estiramento profundo fabricadas internamente através de fresagem CNC e EDM a fio/espelho garantem uma moldagem repetível, flanges ajustadas e raios limpos para a adaptação de PCBs.

- Metalurgia: Estampagem progressiva de alta velocidade, corte a laser, dobragem CNC e estampagem profunda controlada para preservar a estrutura do material e as propriedades de elasticidade.

- Juntagem e Montagem: Soldadura por pontos de precisão, soldadura TIG, soldadura a laser e clinchagem para costuras ou características de montagem integradas. Dobragem e flangeamento para bordas seguras para o utilizador e superfícies de acoplamento robustas.

- Preparação da Superfície e E-Coat: As peças passam por um processo de limpeza e pré-tratamento em várias etapas (lavagem alcalina, desoxidação). A deposição eletroforética (E-coating) produz revestimentos uniformes e conformes em geometrias complexas; curados em fornos controlados para atingir a espessura de filme especificada.

- Acabamentos Secundários: Polimento eletrolítico opcional, passivação ou revestimento em pó sobre o e-coat onde é necessária resistência estética ou química adicional. Estão disponíveis ranhuras para juntas, aplicação de tinta condutora ou epóxi prateado, e integração de juntas RF.

Opções de Tratamento de Superfície e Revestimento

- Revestimento Eletroforético (E-Coat): Proteção contra corrosão uniforme; excelente base para revestimentos subsequentes; espessura típica de filme 5–25 μm.

- Electropolimento: Reduz a rugosidade da superfície, melhora a resistência à corrosão e a integridade do contacto onde é necessário contacto metal com metal.

- Passivação (Nítrica / Cítrica): Restaura a camada de óxido de cromo do aço inoxidável para uma resistência à corrosão aprimorada.

- Revestimentos Condutores / Revestimento Seletivo: Revestimento seletivo de prata ou níquel para melhorar a condutividade de contacto em superfícies de vedação ou de acoplamento.

- Revestimento em pó / Acabamento em poliéster: Acabamentos decorativos resistentes às intempéries sobre e-coat para aplicações exteriores ou estéticas.

- Integração de Gaskets Personalizados / Gaskets EMI: Integração de silicone, espuma condutora ou contactos de mola para montagens de alta SE.

Desempenho Elétrico e Mecânico

- Efetividade de Blindagem (SE): Projetada e verificada para a SE alvo utilizando medições em laboratório; desempenho típico de 40–80 dB entre 100 kHz e 6 GHz, dependendo do design, costuras e vedação. Validação da SE de acordo com os requisitos do cliente (IEEE 299, MIL-STD-285 ou equivalente disponível).

- Integridade Mecânica: A geometria profundamente moldada oferece uma elevada relação rigidez/peso e tensão de mola repetível para montagens por pressão ou montadas com parafuso.

- Térmico e Ambiental: O revestimento E-coat, juntamente com a construção em aço inoxidável, suporta uma ampla gama de temperaturas e resiste à humidade, à névoa salina e a agentes de limpeza comuns.

Garantia de Qualidade

Aplicamos um rigoroso programa de QA em controlo de materiais, ferramentas, produção e inspeção final.

- Inspeção de Entrada: Verificação química e mecânica (certificados de material, dureza e espessura).

- Controlo Dimensional: CMM, digitalização óptica 2D/3D e monitorização SPC para garantir a forma, a posição dos furos e as tolerâncias críticas.

- Revestimentos e Ensaios de Superfície: Medição da espessura do filme (XRF / corrente de Foucault), ensaios de adesão (crosshatch), ensaios de corrosão por névoa salina (ASTM B117) e verificações de brilho/aparência.

- Teste Elétrico: Validação da eficácia de blindagem, verificação da resistência de contacto nas superfícies de acoplamento e testes de continuidade onde aplicável.

- Rastreabilidade do Processo: Codificação de lotes serializados, relatórios de Inspeção do Primeiro Artigo (FAI), indexação da capacidade do processo (Cp/Cpk) em dimensões críticas.

Aplicações

- Latas e capas de blindagem EMI/RFI para PCB para: estações base de telecomunicações, routers, eletrónica médica, controladores industriais, ECUs automotivos, aviónica aeroespacial e instrumentação de precisão.

- Fechamentos e divisórias internas que requerem tanto proteção eletromagnética como proteção mecânica.

Perfil da Fábrica (um parágrafo)

A nossa instalação combina a precisão na conformação de metais e a experiência em acabamentos superficiais para fornecer soluções completas de blindagem: sala de ferramentas para a fabricação de matrizes progressivas e de fundo (CNC, EDM, WEDM), prensas de estampagem progressiva e de fundo de vários toneladas, linhas de corte a laser e de dobragem CNC, células automatizadas de soldadura por pontos/laser, e linhas dedicadas de e-coating com fornos de cozedura controlados. O pós-processamento inclui eletropolimento, passivação, análise de revestimento por XRF e uma capacidade interna de teste EMI para verificação de blindagem. Fluxos de trabalho alinhados com ISO 9001 e IATF, monitorização SPC e total rastreabilidade de materiais garantem peças consistentes e prontas para produção, desde protótipos até produções em alta volume.