In today’s fast-paced manufacturing environment, the demand for complex, high-precision metal components delivered with short lead times has never been higher. Industries ranging from automotive and aerospace to consumer electronics and medical device manufacturing are constantly seeking ways to optimize production cycles without compromising quality. At Plantmetal, we specialize in advanced metal stamping processes that help our clients stay competitive — and one of the most effective solutions we offer is the integration of progressive stamping and deep drawing in a composite die setup.

If you’re currently searching for a reliable stamping partner capable of handling intricate parts with consistent dimensional stability and surface quality, let’s explore how our expertise in composite stamping can address your production challenges.

What Is Progressive and Estampagem profunda Composite Stamping?

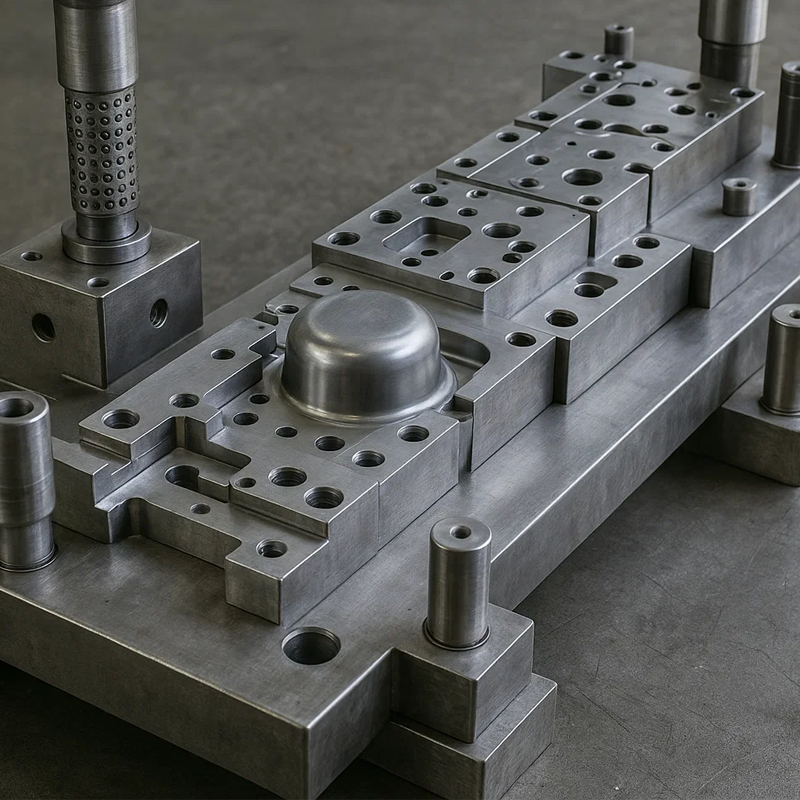

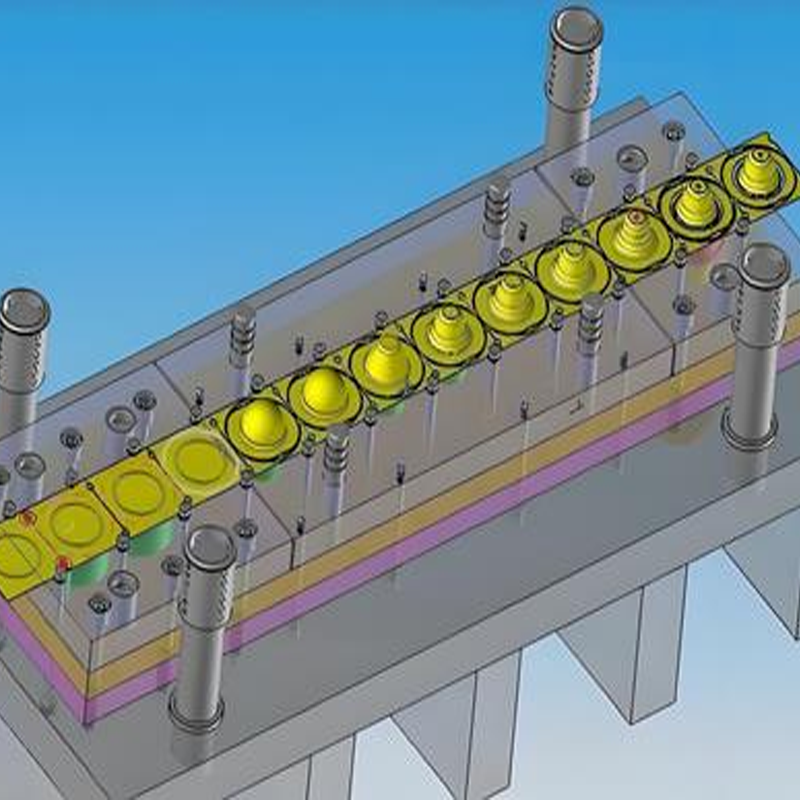

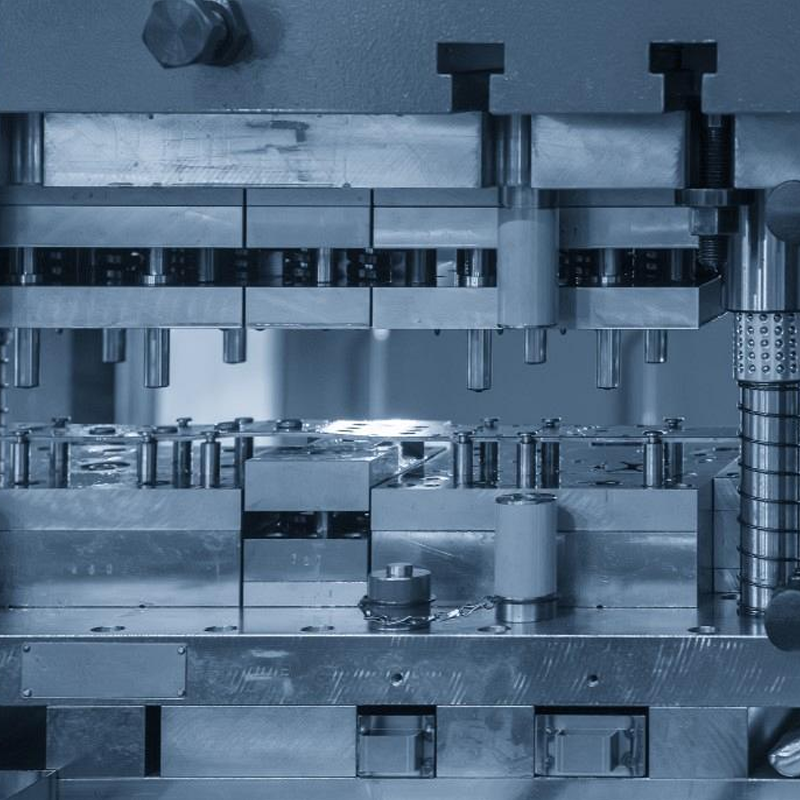

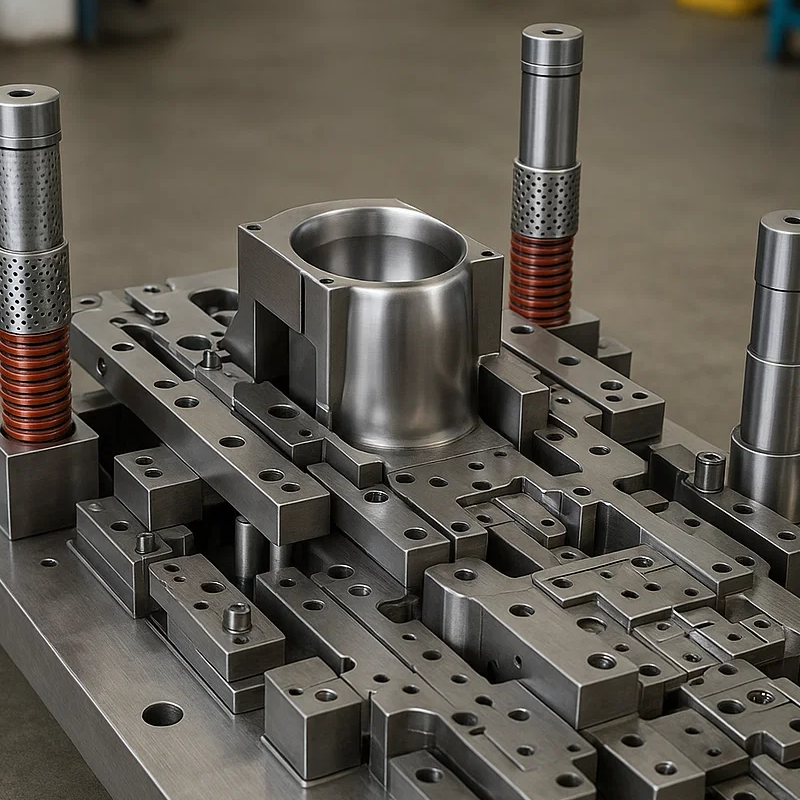

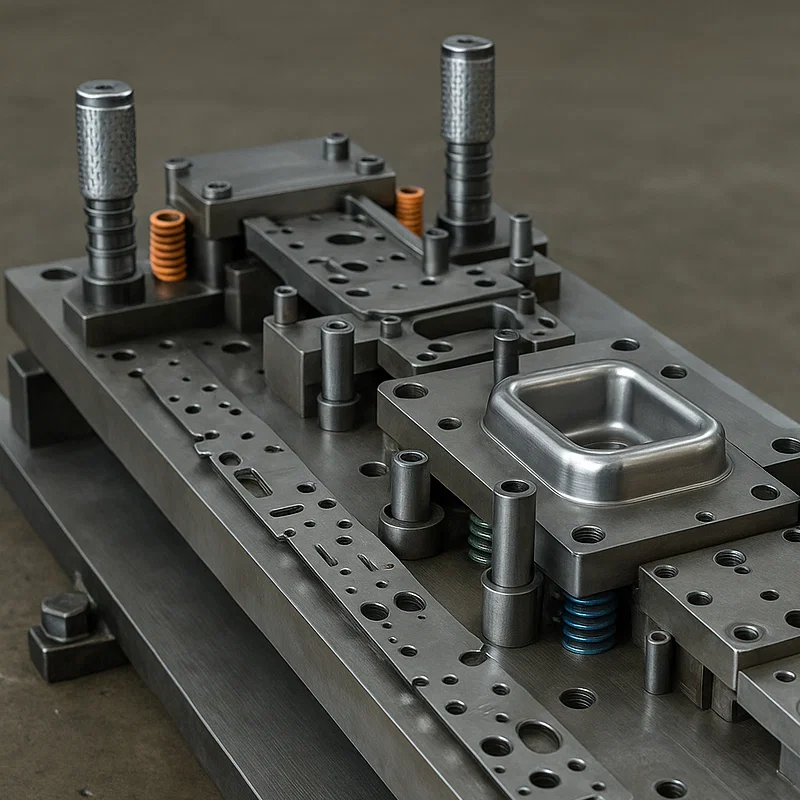

This composite process combines multiple forming operations within a single die. In a progressive stamping tool, the metal strip moves through sequential stations where it undergoes incremental forming actions — such as piercing, bending, and trimming. Deep drawing, on the other hand, involves gradually forming flat sheet metal into a deep, cup-like or cylindrical shape.

When these two are integrated, it enables complex shapes to be formed, trimmed, and finished all within one continuous stamping operation. This “one-stop” in-die forming process dramatically improves efficiency while reducing handling, tooling, and secondary operation costs.

Why Is This Technology Gaining Attention?

Several factors are driving the rising interest in progressive-deep drawing composite stamping processes:

- High-Volume Production with Reduced Cycle Time

By integrating multiple operations into one stamping pass, the total production time per part is significantly lowered — crucial for industries like automotive and electronics, where time-to-market is vital. - Improved Dimensional Consistency

Performing deep drawing and subsequent operations in a single, closed-loop tooling system minimizes tolerance stack-ups and alignment errors. - Reduction in Secondary Operations

Parts come off the line with fewer burrs and require less downstream processing like deburring, welding, or surface finishing. - Cost-Efficient for Complex Shapes

The technology allows the economical production of intricate geometries — which might otherwise require expensive multi-step machining processes.

Key Customer Concerns — And How Plantmetal Solves Them

As a leading stamping solution provider, we understand what customers prioritize when adopting composite stamping processes:

1. Material Formability Challenges

High-strength steels, stainless steels, and aluminum alloys — while popular for their performance — are notorious for cracking and wrinkling during deep drawing.

Our solution: At Plantmetal, we optimize blank holder pressure, draw bead configurations, and progressive tool clearances to prevent defects like splits or thinning.

2. Tooling Durability and Precision

Handling multiple operations within one die increases tooling complexity and wear risks.

Our approach: We use premium tool steels (like DC53, SKD11) with advanced surface treatments (PVD coatings, nitriding) to extend tool life while maintaining tight tolerances.

3. Dimensional Accuracy and Consistency

Especially in applications like medical or precision electronics, customers demand ultra-stable part dimensions.

Our strategy: Real-time in-line quality monitoring systems combined with advanced CAD/CAM-assisted DFM analysis ensure accuracy throughout production.

4. Production Lead Times

In competitive markets, customers cannot afford long tooling setup times.

Our advantage: By investing in modular composite tooling systems and rapid tool change capabilities, we drastically reduce setup and turnaround times.

Practical Applications Across Industries

Composite progressive-deep drawing stamping is already revolutionizing several sectors:

- Automotive: Battery cell housings, bracket systems, airbag components

- Consumer Electronics: Heat sinks, EMI shielding cases, speaker frames

- Medical Devices: Surgical instrument handles, canisters, implant enclosures

- Aerospace: Fuel system components, control housings

Conclusion:

If you’re exploring ways to cut production costs, improve product precision, and consolidate forming processes into one efficient solution, composite progressive-deep drawing stamping might be your answer. At Plantmetal, we bring over a decade of experience in high-precision stamping and tool design, offering in-house tooling fabrication, advanced simulation software, and ISO-certified quality management systems.

We’d love to learn more about your upcoming project challenges and explore how our solutions can help you optimize your metal parts production. Contact our technical team today — and let’s engineer a better, smarter stamping solution together.

Would you like us to prepare a tailored technical DFM review or a quick feasibility analysis for your part drawings? Get in touch with Plantmetal and we’ll be happy to assist.