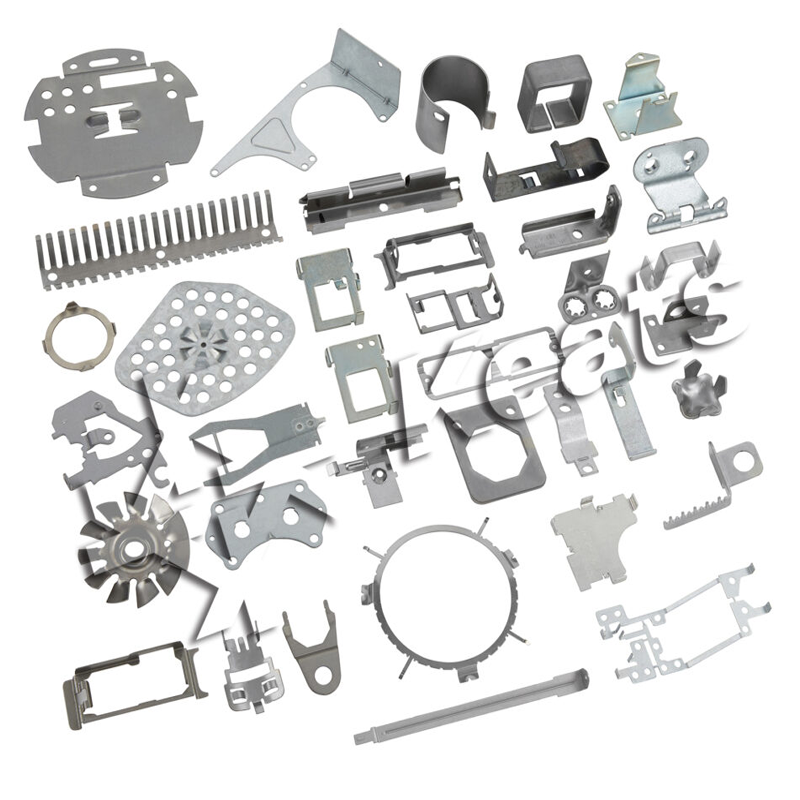

Are you in search of a reliable partner—one that can handle every step from material selection to finished stamping—in your pursuit of high‑strength, precision‑stamped components? At Plantmetal, we pride ourselves on being more than just another supplier; we’re your one‑stop service provider for custom metal stamping solutions. Whether you’re an OEM or one of many manufacturers seeking trusted suppliers for High‑Strength Low‑Alloy (HSLA) parts, our goal is to collaborate with you to deliver parts that exceed expectations in the most demanding environments.

Why HSLA Steels Are the Material of Choice for High‑Stress Applications

When safety and performance are on the line, HSLA steels offer an unmatched combination of properties:

- Superior Strength‑to‑Weight Ratio: HSLA alloys deliver high yield strength without the weight penalty of traditional alloy steels.

- Enhanced Corrosion Resistance: Tight control of microalloying elements provides better resistance to rust and environmental degradation.

- Outstanding Durability: Excellent fatigue performance makes HSLA ideal for parts subjected to repeated loading cycles.

These characteristics make HSLA steels the go‑to materials for structural brackets, chassis reinforcements, vehicle frames, and industrial enclosures that must withstand heavy loads and harsh operating conditions.

Overcoming the Forming Challenges of HSLA Steels

The very attributes that make HSLA alloys attractive also introduce significant stamping challenges. Partnering with a knowledgeable manufacturer—one equipped with both advanced machinery and deep material expertise—is essential. Here’s a look at the most common hurdles and how Plantmetal addresses them:

1. Springback Control

Challenge: HSLA steels have high elastic recovery, causing stamped parts to “spring back” and deviate from intended dimensions.

Plantmetal Solution:

- Finite Element Analysis (FEA)‑Driven Die Design: We simulate forming sequences to predict springback and incorporate compensation features into our tooling.

- Progressive Die Staging: By using multi‑stage progressive dies, we distribute deformation gradually, reducing the elastic rebound that occurs after a single heavy draw.

2. Avoiding Cracking in Deep Draws

Challenge: If the material is stretched too aggressively or lubrication is insufficient, HSLA parts can crack—especially in corners and tight radii.

Plantmetal Solution:

- Optimized Draw Beads and Die Radii: We engineer each die with draw beads that control material flow and generous radii that minimize stress concentrations.

- Specialized Lubrication Systems: Our in‑die lubrication spray and wipe stations ensure even coverage, reducing friction and void formation during deep draws.

3. Mitigating Tool Wear

Challenge: The hardness and abrasion resistance of HSLA alloys can accelerate die wear, impacting part consistency over long runs.

Plantmetal Solution:

- Wear‑Resistant Coatings: We apply PVD coatings (e.g., TiN, DLC) to critical die surfaces, extending tool life by up to 300%.

- Proactive Maintenance Regimen: Our one‑stop service includes scheduled tool inspections and refurbishments, ensuring you never face unexpected downtime.

Plantmetal’s Custom Metal Stamping Capabilities for HSLA Components

At Plantmetal, our vision is to serve as your comprehensive stamping partner—from prototype through high‑volume production—with fully integrated services that cover every need.

High‑Tonnage Presses for Forming High‑Strength Materials

Our press fleet includes hydraulic and mechanical presses up to 1,000 tons, empowering us to handle:

- Large Panels and Enclosures: Flat or complex shapes that require uniform forming force.

- Multi‑Stage Progressive Operations: Inserts, extruded lances, and compound bends—all executed in a single strip of HSLA feed material.

- High‑Precision Tolerance Control: Presses equipped with load monitors and servo‑controlled cushion systems to maintain ±0.002″ repeatability.

In‑House Tooling: Precision from Concept to Completion

By designing and manufacturing our own tooling, we maintain absolute control over:

- Material Flow Management: Custom die clearances ensure consistent part thickness and eliminate wrinkling or thinning.

- Dimensional Accuracy: Each tool is inspected via Coordinate Measuring Machines (CMMs) to guarantee that the first article meets your CAD model.

- Rapid Iteration: Should you need design modifications, our tool shop can implement changes quickly—minimizing lead time from concept validation to production.

Simulation & Prototyping: De‑Risking Your Program

Before committing to full production, we leverage:

- Virtual Forming Simulations: FEA and stamping software identify potential trouble spots—springback, thinning, or wrinkling—so we can refine tooling designs upfront.

- Short‑Run Prototyping: Pilot runs on lab‑scale presses allow you to validate form, fit, and function with actual HSLA material before scaling up.

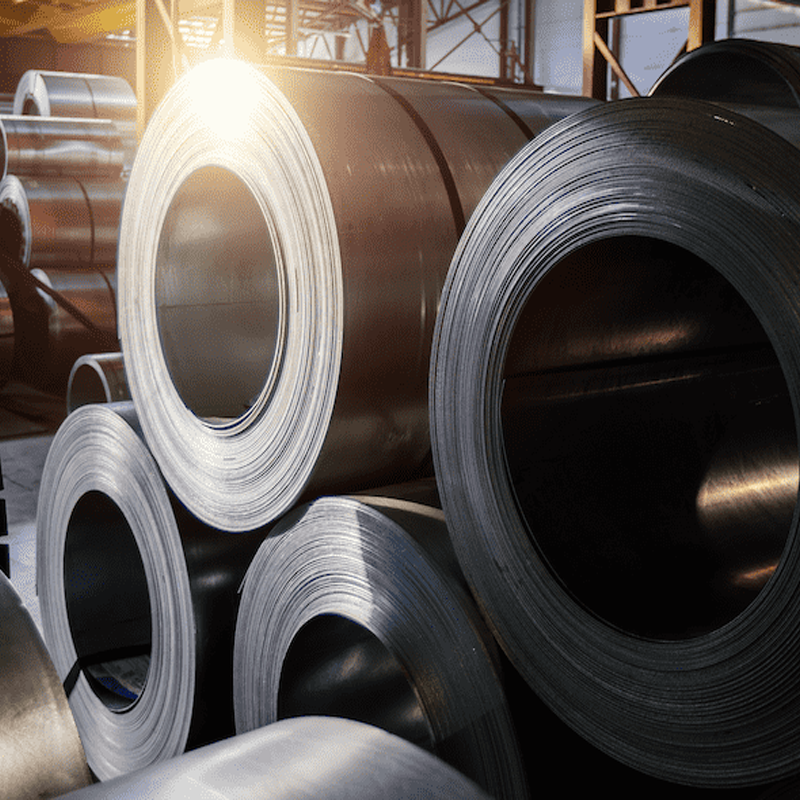

Material Expertise: Beyond the Spec Sheet

Not all HSLA steels are created equal. The choice of grade and temper can dramatically affect formability, performance, and cost. As a leading one‑stop service provider, Plantmetal:

- Analyzes Application Requirements: We consider load‑bearing demands, corrosion environments, and fatigue cycles to recommend the optimal alloy (e.g., A1011, HSLA 350, HSLA 420, etc.).

- Selects the Right Temper: Balancing yield strength and elongation to ensure both performance in service and formability during stamping.

- Optimizes Gauges: Thinner gauges can reduce weight but may challenge draw limits—our engineers model these trade‑offs to hit your targets.

By blending metallurgy with manufacturing know‑how, we help you avoid costly material changes or re‑stamping down the road.

Rigorous Quality Assurance for High‑Stress HSLA Parts

In critical applications, every stamped part must consistently meet stringent specifications. Plantmetal’s quality regimen for HSLA components includes:

- CMM Inspection: Automated CMM stations verify feature locations, radii, and flatness against tight tolerances (±0.002″).

- Vision Inspection Systems: High‑speed cameras spot surface defects—scratches, scale, or form errors—immediately after stamping.

- In‑Line Gauging: Real‑time thickness and draw depth measurements ensure continuous process control.

- Traceability & Documentation: Full lot tracking, material certifications, and Inspection Test Reports (ITRs) to satisfy IATF 16949, ISO 9001, and customer‑specific requirements.

Our defect prevention strategies—root‑cause analysis, SPC charts, and poka‑yoke fixtures—ensure you receive parts that are ready to install, without rework or scrap.

Scaling HSLA Production: From Low‑Volume to High‑Mix Programs

Whether you need a thousand brackets per month or a high‑mix mix of several dozen part numbers, Plantmetal’s flexible manufacturing platform can handle your requirements:

- Adaptive Tooling Cells: Quick‑change die mounts and modular die stations let us swap over to different HSLA components in minutes, reducing downtime.

- Batch & Continuous Production: Our scheduling integrates pilot runs, bridge tooling, and long‑run presses to meet evolving production plans.

- Integrated One‑Stop Service: From blanking and lamination to final assembly and packaging, we coordinate with sub‑suppliers or internal operations to deliver end‑to‑end solutions.

This scalability, combined with our material and process expertise, positions Plantmetal as the ideal supplier for manufacturers seeking trusted HSLA stamping services.

Partner with Plantmetal: Your HSLA Stamping Authority

High‑Strength Low‑Alloy steels unlock extraordinary performance—but only when stamped precisely, consistently, and cost‑effectively. At Plantmetal, we offer a true one‑stop service—from material sourcing and engineering analysis to prototyping, stamping, finishing, and quality documentation. Whether you’re managing a complex supply chain with multiple suppliers or consolidating with a single trusted manufacturer, our team is ready to align with your goals for strength, durability, and efficiency.

Let’s discuss your next HSLA stamping project. Contact Plantmetal today to explore how our advanced equipment, in‑house tooling, and comprehensive services can elevate your components—meeting and exceeding the toughest performance standards in automotive, aerospace, industrial, and beyond.