Обзор:

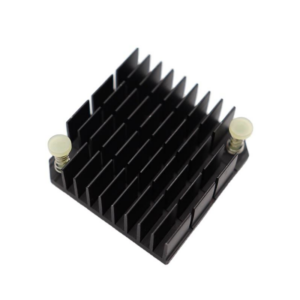

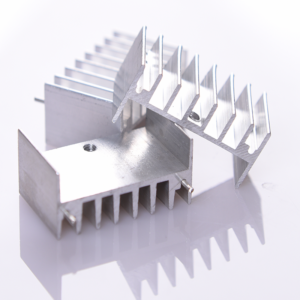

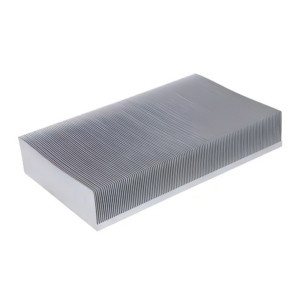

Мы производим высокопроизводительные металлические штампованные радиаторы из нержавеющей стали для приложений печатных плат BMS (систем управления батареями), обеспечивая эффективное тепловое управление и отличную механическую надежность. Изготовленные из высококачественной нержавеющей стали, наши радиаторы спроектированы для эффективного рассеивания тепла, что обеспечивает оптимальную работу и надежность электронных систем на основе печатных плат. Поверхность обработана прочным порошковым покрытием для повышения коррозийной стойкости, эстетики и улучшенной долговечности в сложных условиях.

С помощью современных технологий штамповки металлов, фрезеровки с ЧПУ и точной сварки мы достигаем строгих допусков и однородного качества. В качестве надежного партнера в области оригинального оборудования (OEM) мы предлагаем комплексные решения — от быстрого прототипирования до серийного производства, поддерживаемые обширными испытаниями на тепловую производительность и механическими испытаниями. Наши индивидуально разработанные радиаторы помогают повысить эффективность и надежность систем управления батареями (BMS), одновременно снижая затраты на сборку.

Основная информация:

| Атрибут | Детали |

|---|---|

| Место происхождения | Сямынь, Китай |

| Название бренда | OEM |

| Материал | Нержавеющая сталь (304, 316 или специальные сплавы) |

| Настройка | Доступно по запросу |

| Образец | Предоставлено по запросу |

| Спецификация | Стандартный или изготовленный по спецификациям клиента |

| Упаковка | Стандартная экспортная упаковка или индивидуальные решения в соответствии с требованиями клиента. |

| Цвет | Настраиваемый в соответствии с предпочтениями клиента |

| Поверхностная отделка | Порошковая покраска, анодирование или другие индивидуальные отделки |

Варианты поверхностного покрытия:

- Порошковое покрытие: Обеспечивает прочное, коррозионно-устойчивое покрытие, идеально подходящее для жестких условий окружающей среды. Порошковое покрытие повышает эстетическую привлекательность и увеличивает срок службы радиатора.

- Электролитическое покрытие: обеспечивает надежную защиту от коррозии, гарантируя долговечность и оптимальную тепловую производительность в условиях повышенных требований.

- Анодирование: Улучшает твердость поверхности и износостойкость, делая радиаторы подходящими для применения в условиях, требующих отличной durability.

- Цинковое и никелевое покрытие: обеспечивает защиту от коррозии и гарантирует надежную работу в течение длительного времени при различных условиях окружающей среды.

Ключевые преимущества:

- Эффективное тепловое управление: Наши радиаторы из нержавеющей стали разработаны для эффективного рассеивания тепла с плат BMS PCB, что обеспечивает долгий срок службы и оптимальную производительность критически важных электронных устройств.

- Настраиваемая обработка поверхности: Мы предлагаем гибкие отделки поверхности, такие как порошковая покраска и гальванизация, чтобы удовлетворить эстетические и функциональные требования.

- Precision Manufacturing: Through high-accuracy metal stamping, CNC machining, and welding, our heat sinks are produced to the tightest tolerances, ensuring consistent quality and precise fitment.

- Сопротивление коррозии: благодаря порошковому покрытию или электрохимическому покрытию наши радиаторы обладают стойкостью к коррозии, что делает их подходящими для высокопроизводительных и жестких промышленных условий.

Обеспечение качества:

Наши OEM металлические штампованные радиаторы из нержавеющей стали проходят строгий процесс контроля качества, чтобы обеспечить высокую производительность и надежность.

- Материальная проверка: Нержавеющая сталь проверяется на чистоту и качество перед производством.

- Дименсиональная точность: Каждый радиатор проходит проверку размеров с использованием координатных измерительных машин (CMM) и 3D лазерных сканеров Zeiss, чтобы обеспечить строгие допуски.

- Тепловое тестирование: Тепловые характеристики испытываются для обеспечения того, чтобы радиаторы соответствовали необходимым требованиям охлаждения для приложений печатных плат BMS.

- Проверка поверхности: Финиш порошкового покрытия, электроосаждения или анодирования проверяется с помощью оптических профилометров и тестеров на адгезию для обеспечения долговечности и однородности.

- Механические испытания: Испытываются прочность на растяжение, твердость и общая структурная целостность, чтобы обеспечить надежность в условиях эксплуатации.

Фабричные возможности:

Наш современный производственный объект оснащен новейшими технологиями для обеспечения точности и высокого качества производства:

- Высокопроизводительные штамповочные прессы: Мы используем 25 высокопроизводительных штамповочных прессов (в диапазоне от 25 до 300 тонн) для стабильного, массового производства с высокой точностью.

- CNC Обработка и Прецизионная Проволочная EDM: Современные системы CNC обработки и прецизионной проволочной EDM обеспечивают точное создание форм и проектирование полостей для оптимальной тепловой производительности.

- Станции порошковой покраски и гальваники: Наше предприятие оснащено современными системами покрытия и гальваники для нанесения прочных, коррозионностойких покрытий на радиаторы.

- Автоматизированная сборка и тестирование: Мы используем автоматизированные сборочные линии, 3D проекторы, испытатели на растяжение и устройства для измерения усадки для тщательного тестирования продукции, обеспечивая надежную работу.

- Сертификаты ISO 9001 и IATF 16949: Наши производственные процессы соответствуют самым высоким отраслевым стандартам, что обеспечивает надежные и точно спроектированные радиаторы для приложений BMS PCB.

Почему выбирают нас?

- Индивидуальные решения: Мы предлагаем индивидуальные дизайны, размеры и отделки поверхностей, чтобы удовлетворить специфические потребности вашей системы BMS и приложений печатных плат.

- Превосходная прочность: Наши радиаторы спроектированы из высококачественной нержавеющей стали и прочных покрытий, что обеспечивает долговечную защиту и тепловое управление.

- Точное машиностроение: Современные технологии производства обеспечивают высокую точность и надежную работу для ваших критически важных электронных приложений.

- Эффективное производство: От быстрого прототипирования до массового производства мы предлагаем быстрое выполнение заказов и надежную доставку, чтобы соответствовать срокам вашего проекта.

- ISO-Сертифицированный Контроль Качества: Процессы обеспечения качества на нашем заводе гарантируют, что каждый радиатор соответствует самым высоким стандартам производительности и глобальным производственным нормам.

Используя передовые технологии и обширный опыт в области тепловых решений, мы предоставляем индивидуальные штампованные радиаторы из нержавеющей стали, которые улучшают производительность, надежность и долговечность ваших систем BMS PCB. Свяжитесь с нами сегодня, чтобы обсудить ваши потребности в индивидуальных радиаторах, и позвольте нам помочь оптимизировать ваш следующий проект.