Обзор:

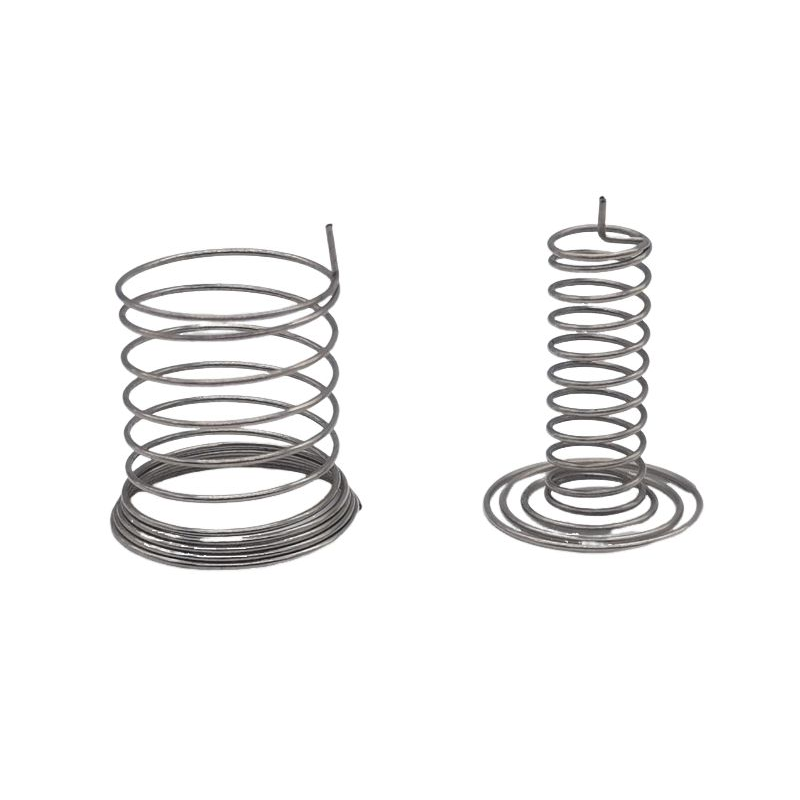

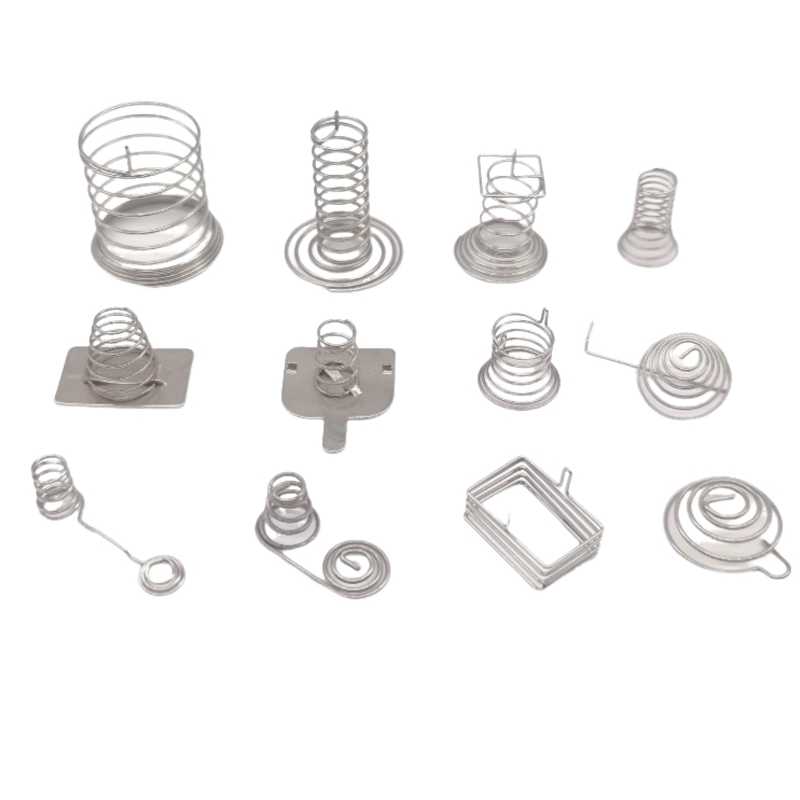

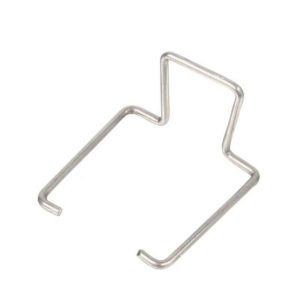

Наши пружины сжатия из нержавеющей стали OEM, предназначенные для растяжения и сжатия, разработаны для точных грузоподъемных приложений в автомобильной, промышленной и потребительской электронике. Изготовленные из высококачественной проволоки из нержавеющей стали, эти пружины проходят передовые процессы ЧПУ-намотки и термообработки, чтобы обеспечить исключительную усталостную прочность, размерную стабильность и защиту от коррозии. С настраиваемыми характеристиками нагрузки, размерами и отделкой наши пружины адаптированы для удовлетворения ваших точных требований к производительности. Поддерживаемые строгим контролем качества и сертификацией IATF 16949/ISO 9001, мы предлагаем комплексные услуги OEM — от прототипирования до серийного производства — чтобы обеспечить надежные решения с длительным сроком службы пружин.

Спецификации:

| Атрибут | Детали |

|---|---|

| Материал | Нержавеющая сталь 302, 304, 316 или специальные сплавы |

| Процесс | ЦПУ Точное Навивание, Стреляние, Термальная Обработка |

| Диаметр проволоки | 0,2 мм – 10 мм (доступны индивидуальные размеры) |

| Внешний диаметр | 1 мм – 100 мм (по дизайну) |

| Свободная длина | 5 мм – 500 мм (настраиваемый) |

| Грузоподъемность | 0.1 Н – 2000 Н (основано на геометрии катушки и материале) |

| Толерантность | Нагрузка: ±5 %; Длина и диаметр: ±0,05 мм (или в соответствии с техническими требованиями) |

| Поверхностная отделка | The translation of the provided terms into Russian is as follows: - Passivation: Пассивация - Electro‑polishing: Электрохимическая полировка - Phosphate Coating: Фосфатное покрытие - Custom: Индивидуальный (or Специальный, depending on context) |

| Сертификация | ISO 9001:2015, IATF 16949, RoHS |

| Наличие образцов | Прототипы доступны в течение 5–10 дней. |

| MOQ | В соответствии с требованием клиента. |

| Упаковка | Индивидуальная упаковка или упаковка оптом с защитными вкладышами. |

| Рабочая температура | –60 °C до +300 °C (в зависимости от выбора материала) |

| Время выполнения | 15–30 дней (в зависимости от сложности и объема) |

Ключевые преимущества:

- Высокая усталостная стойкость

CNC-изготовленные пружины проходят прецизионную термообработку и shot peening, что значительно увеличивает их усталостную прочность при многократных циклах нагрузки. - Коррозионная защита

Изготовленные из высококачественной нержавеющей стали и отделанные пассивацией или электрохимической полировкой, эти пружины устойчивы к ржавчине и окислению в жестких условиях. - Кастомные нагрузки и точность размеров

Современные технологии намотки и строгий контроль процессов обеспечивают пружины с точными нагрузочными характеристиками и размерными допусками, соответствующими критическим требованиям применения. - OEM и Поддержка Быстрого Прототипирования

От малосерийного прототипирования до массового производства, наши внутренние команды по инструментальному производству и инженерии предлагают полную кастомизацию, обеспечивая быструю реализацию и бесшовную интеграцию в ваш дизайн.

Обеспечение качества:

Наша программа контроля качества сертифицирована по стандартам ISO 9001 и IATF 16949 и включает строгие многоступенчатые проверки. Мы используем оптические компараторы для проверки размеров, испытатели пружин для точности нагрузки и хода, а также камеры солевого тумана для проверки коррозионной стойкости. Каждая партия проходит выборочную проверку, а финальные инспекции гарантируют, что каждая пружина соответствует или превышает спецификации производительности перед отправкой.

Обзор завода:

Наше предприятие оснащено современными ЧПУ-станками для намотки пружин, высокоточными выпрямителями проволоки и современными печами для термообработки. Мы также поддерживаем камеры для shot-peening и несколько линий для финишной обработки поверхностей, включая пассивацию, электрохимическую полировку и нанесение покрытий. В наших комплексных испытательных лабораториях имеются автоматизированные стенды для испытания пружин, оптические системы измерения и климатические камеры для обеспечения целостности продукции.

Наше предприятие оборудовано современными станками для намотки пружин с ЧПУ, прецизионными выпрямителями проволоки и новейшими печами для термообработки. Мы также поддерживаем камеры для shot-peening и несколько линий для обработки поверхности для пассивации, электрохимической полировки и нанесения покрытий. Комплексные испытательные лаборатории на месте оснащены автоматическими испытателями пружин, оптическими измерительными системами и климатическими камерами для обеспечения целостности продукции.