In the world of Металлическая штамповка, ensuring the production of flawless components is crucial for maintaining both performance and customer satisfaction. As a leading manufacturer in the industry, Plantmetal understands the importance of high-quality, defect-free parts, especially when dealing with critical applications such as automotive, aerospace, and electronics. One of the major challenges faced by manufacturers is detecting surface defects such as scratches, bubbles, and dents, which can significantly affect the function and appearance of stamped metal parts. This is where advanced technologies like visual inspection systems, laser scanning, and automated defect detection play a vital role.

The Role of Real-Time Surface Defect Detection

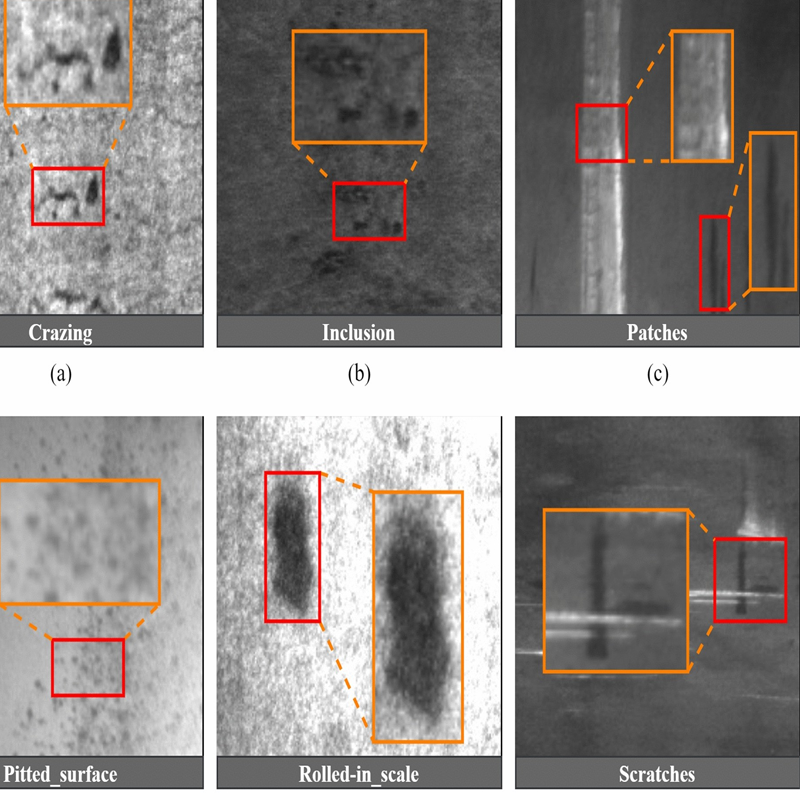

Surface defects such as scratches, bubbles, and scuffs are common during the metal stamping process, especially when handling materials like aluminum, steel, and stainless steel. These defects can occur due to a variety of reasons, including improper handling, tooling errors, or material flaws. Detecting these defects in real-time can drastically improve production efficiency, reduce rework costs, and ensure that only parts meeting the highest quality standards reach customers.

At Plantmetal, we leverage cutting-edge technologies to enhance our quality control processes, ensuring every stamped part adheres to the most stringent standards.

Visual Inspection Systems for Metal Stamping Defects

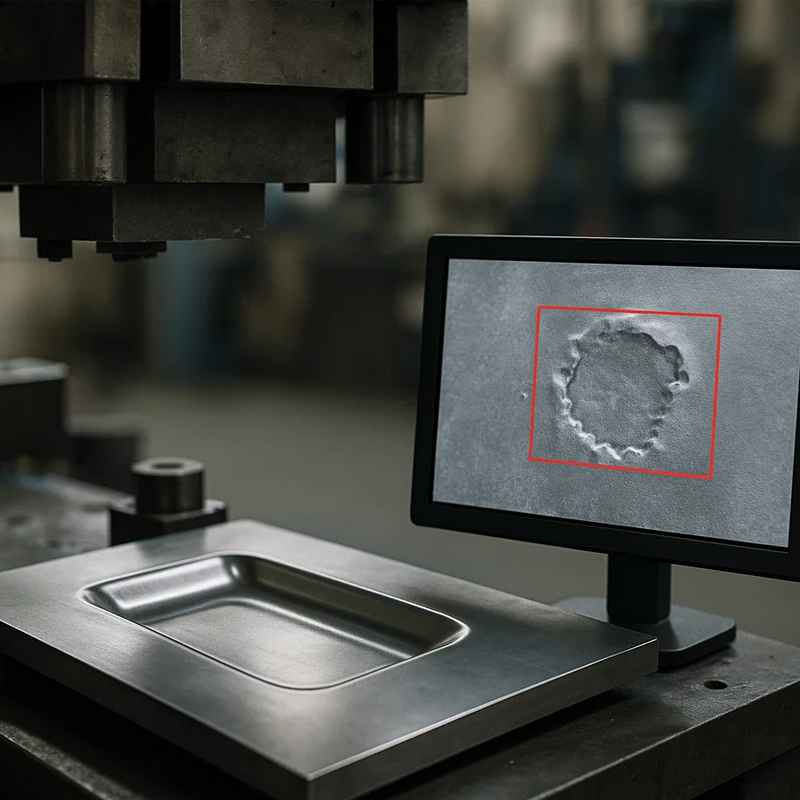

Visual inspection is one of the most widely used methods for detecting surface defects on metal stamping parts. Modern visual inspection systems are equipped with high-definition cameras and advanced image processing software that can detect even the smallest scratches, dents, and bubbles on metal surfaces. These systems use artificial intelligence (AI) and machine learning to identify and classify defects in real-time, providing instant feedback during production.

By utilizing automated visual inspection, we at Plantmetal can achieve the following:

- Real-Time Defect Detection: Detecting defects as they occur prevents flawed parts from advancing further in the production process.

- Minimized Human Error: Automated visual inspection removes the risk of human error, ensuring consistent and reliable results.

- Increased Efficiency: With real-time analysis, any defective parts can be immediately flagged, reducing downtime and improving overall throughput.

- Reduced Costs: Identifying defects early in the production process reduces the need for costly rework and scrap materials.

These advantages make visual inspection systems an invaluable tool for ensuring high-quality standards in metal stamping operations.

Laser Scanning Technology for Surface Inspection

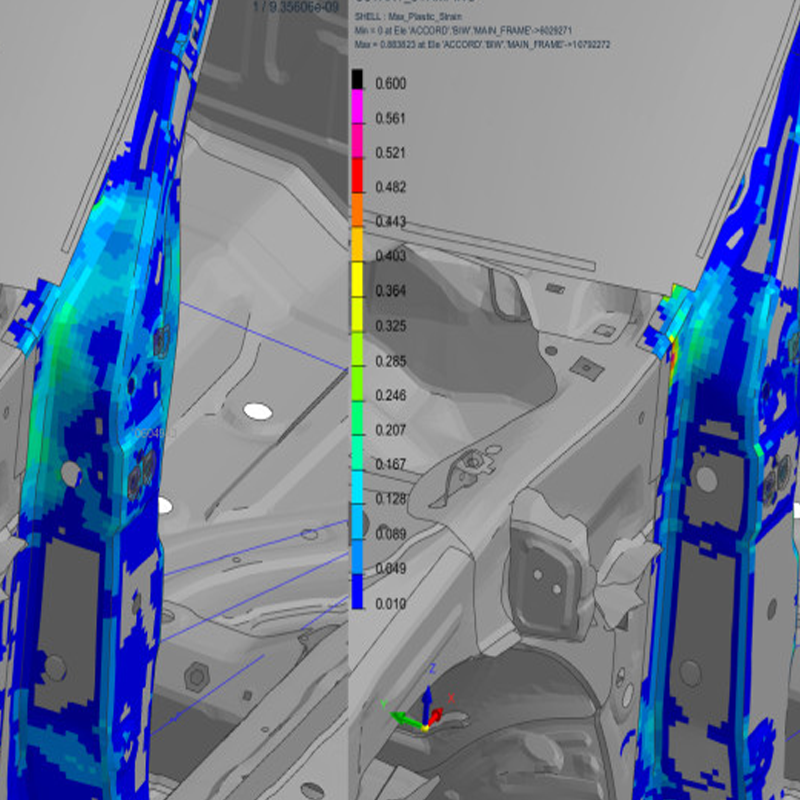

Another revolutionary technology gaining popularity in the metal stamping industry is laser scanning. Laser scanning technology uses high-precision lasers to scan the surface of stamped parts, detecting even the most minute surface imperfections. This method is ideal for identifying defects like scratches, dents, and bubbles, which may not be visible through traditional inspection methods.

How laser scanning benefits metal stamping quality control:

- High Precision: Laser scanners can detect even the tiniest surface deviations with high accuracy, ensuring that parts meet tight tolerances.

- Contactless Inspection: Since the laser does not physically contact the surface, there is no risk of damage to delicate or intricate stamped parts.

- Data Capture and Analysis: Laser scanners generate detailed 3D surface maps, enabling us to identify defects in all three dimensions. This provides a comprehensive view of the part’s quality.

- Non-Destructive Testing: Laser scanning is a non-destructive testing method, meaning that the parts remain intact after inspection, ready for further use or packaging.

At Plantmetal, we use laser scanning to complement visual inspection systems, creating a multi-layered approach to detecting and addressing defects at the earliest stage possible.

Benefits of Implementing Real-Time Surface Defect Detection at Plantmetal

By integrating visual inspection systems and laser scanning technologies into our production line, Plantmetal has been able to achieve:

- Faster Detection: These systems allow us to detect defects in real-time, ensuring minimal downtime and swift corrective actions.

- Enhanced Customer Satisfaction: With automated, high-precision defect detection, we deliver consistently high-quality stamped parts, ensuring that customers receive products that meet or exceed their expectations.

- Increased Throughput: Automated systems help speed up the inspection process without compromising on quality, allowing us to maintain high production rates and meet tight deadlines.

- Compliance with Industry Standards: Using advanced defect detection technologies helps us meet industry standards for quality control, particularly in highly regulated sectors like aerospace and automotive manufacturing.

Real-Time Data and Reporting

Another critical advantage of using these advanced technologies is the ability to collect real-time data. Both visual inspection systems and laser scanners generate valuable data during the inspection process, including defect rates, types of defects, and patterns. This data can be used for process optimization, tracking trends, and identifying potential issues in the manufacturing process.

At Plantmetal, we use this data to continuously improve our processes, monitor production quality, and implement proactive measures to reduce defects in future runs.

Overcoming Challenges in Surface Defect Detection

While visual inspection systems and laser scanning technologies offer significant advantages, integrating them into a production line can come with challenges. For instance, ensuring the accuracy of defect detection in complex geometries and varied surface textures requires careful calibration and regular maintenance of equipment. Additionally, laser scanning systems may struggle with certain materials, such as highly reflective metals, which can interfere with accurate measurements.

To mitigate these challenges, Plantmetal invests in ongoing training for our quality control teams and conducts regular system maintenance to ensure that our defect detection technologies are always performing at their peak. We also work closely with equipment suppliers to stay updated on the latest advancements in inspection technology, allowing us to adapt and optimize our systems for the best results.

Partnering with Plantmetal for Precision Metal Stamping

In today’s competitive manufacturing landscape, delivering high-quality metal stamping parts with zero defects is crucial. At Plantmetal, we leverage advanced surface defect detection technologies like visual inspection systems and laser scanning to ensure that every part meets the highest quality standards.

Whether you’re in need of precision stamping for automotive, aerospace, or electronics applications, we are equipped to meet your needs with a commitment to quality, efficiency, and customer satisfaction. If you’re looking for a trusted partner to help you produce flawless metal stamped parts, contact us today. Let’s discuss how our innovative technologies and expertise in metal stamping can help bring your projects to life with precision and reliability.

Together, we can ensure your products meet the highest standards of quality. Reach out to Plantmetal to explore how our advanced surface defect detection technologies can enhance your production process.